How To Determine The Accuracy Of Your CNC Machine Shop

March 20, 2023

How To Determine The Accuracy Of Your CNC Machine Shop

The quality of CNC machined parts depends on many factors, including part design, tool selection, tool path programming, machinist skill set, workpiece clamping strategy, etc. Critical path functional components, such as robotic arms for laser surgery or landing gear components of high-performance aircraft, must operate reliably. Reliability requires accuracy, precision, and the ability of the CNC machining shop that manufactures the parts to maintain tight tolerances.

In order to maintain the precision and precision required for milling parts, a good machining shop will prioritize the following points in its process and procedures:

Working Environment:

The accuracy depends on the working environment that provides stable conditions such as temperature and humidity.

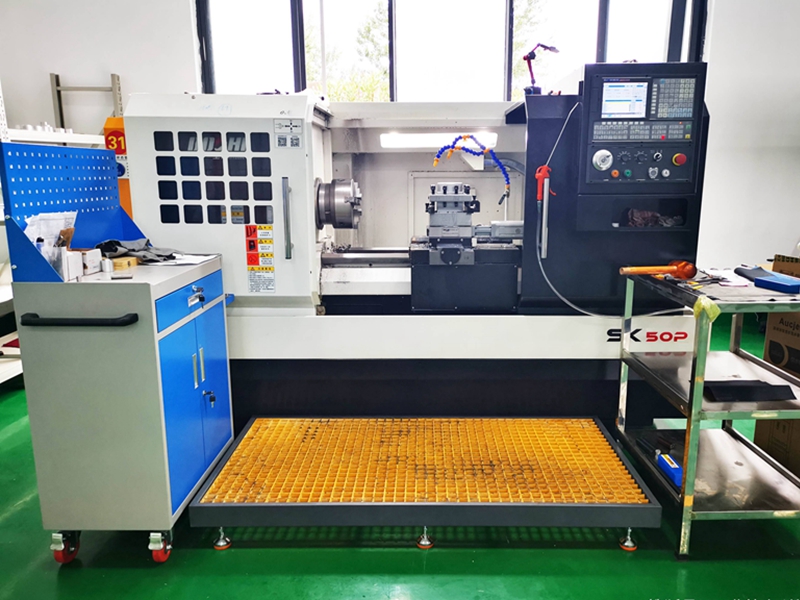

Equipment Status:

CNC milling accuracy requires consistent preventive maintenance to keep all equipment in perfect operating condition.

Machine Calibration:

The machine shop must periodically recalibrate all precision milling equipment to maintain its factory settings.

Accuracy Of CNC Milling: 3 Measurements

Three different measurements determine the overall accuracy of the milled part: position accuracy, accuracy or repeatability, and tolerance.

Position Accuracy

The position accuracy is equal to the difference between the specified distance between the points on the part and the actual measured distance of these points after milling. For a CNC milling machine, accuracy depends on its ability to follow its programmed path. The machining shop determines the accuracy of the rolling mill by taking multiple measurements and calculating the statistical average of the deviations.

Repeatable Accuracy

The machining shop defines the accuracy of the milling machine by precisely repeating the same commands so that one part after the other provides the same result. Similar to accuracy, the workshop can calculate the accuracy of the CNC milling machine through multiple measurements when commanding the machine’s cutting path. The measure of accuracy lies in the repeatability of cutting the same precise path, resulting in an accurate copy of the part over and over again.

Finished Product Tolerance

Machinists and engineers use the term tolerance when referring to the allowable deviation from the CNC milling machine to measure the set value. CNC programmers and machinists program the milling machine to manufacture parts within the tolerances required by the customer. When cutting materials and producing parts, the milling machine should stay within the set tolerance of the specified measurement value.

The goal of a CNC milling machine is to keep it within a specified tolerance range by repeatedly maintaining high positioning accuracy. For example, imagine shooting an arrow at a target. The distance between the arrow and the bull’s eye measures accuracy. Arrow finds that the closeness of its grouping is equal to the repeatable accuracy. Repeatability without precision when machining a batch of parts will not produce any useful results, because the parts are also out of tolerance. Or, accuracy without repeatability will result in only one or two parts available. The combination of precision and repeatability will produce whole batches of intact products. The machining shop uses this precision to ensure the quality of your parts.

Tool Monitoring:

The shop must also monitor the cutting tools—they wear out over time—for maintenance or replacement.

Workpiece Clamping:

In order to minimize vibration and ensure accuracy, the shop must use proper workpiece clamping settings to hold the workpiece in place for processing.

Machinist Experience:

Experienced machinists are more likely to understand the nuances that lead to the manufacture of precise parts.

Programming:

Skilled manufacturing engineers understand how to use different tools, with different methods and speeds, to efficiently manufacture precise CNC milled parts.

Whenever parts are set up on the rolling mill, a high-quality machining shop should have a documented first article inspection process. It will also have regular checkpoints throughout the manufacturing process for quality control.