Blog

Read informational articles, guides & tips, Learn about the manufacturing world in China

The Benefits of CNC Machining over 3D Printing

For manufacturers that need to produce high-quality, durable parts with tight tolerances, CNC machining is the superior choice. On the other hand, 3D printing excels in customization, prototyping, and niche applications, but its limitations in material strength and production speed make it less suitable for high-volume manufacturing.

When choosing between CNC machining and 3D printing, it’s essential to consider the specific needs of the project, including material requirements, production volume, and budget. For most large-scale manufacturing applications, CNC machining offers a more efficient, reliable, and cost-effective solution.

CNC Milling vs CNC Turning-The Differences

CNC Milling vs CNC Turning-The Differences Before we go on to discuss the difference between CNC milling and CNC turning, let’s define what CNC milling is. A CNC machine works towards producing a finished product through an automated process, receiving commands from a computer with pre-programmed software. What is CNC milling? Turning is a process in which a workpiece rotates …

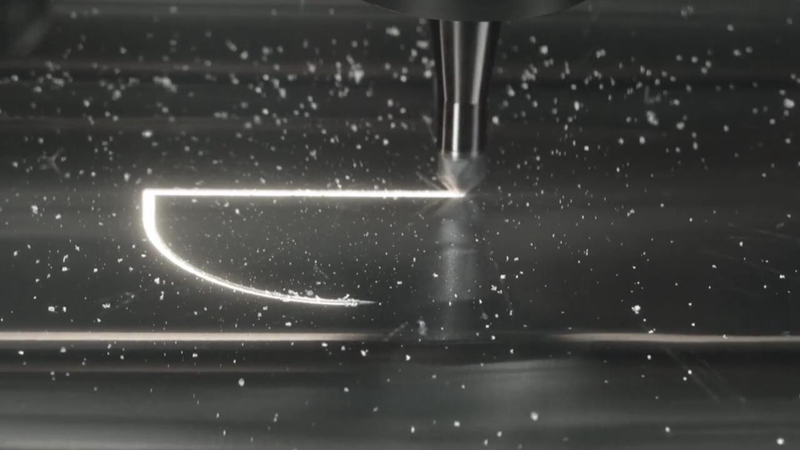

How to Control the Precision of CNC Milling Machining

How to Control the Precision of CNC Milling Machining The quality of CNC machined parts depends on many factors, including part design, tool selection, tool path programming, machinist skill set, workpiece clamping strategy, Position Accuracy, etc. Follow these methods of improving CNC machine accuracy and productivity. get the most out of the equipment you have and increase your project precision. …

Types of CNC Milling Operations

Types of CNC Milling Operations Various types of CNC milling operations are designed to achieve specific outcomes depending on the material type. These operations differ in the type of cutting tool used, the cut’s direction, the cut, the depth of the cut, the speed & feed rate, and other machining parameters. In addition, choosing the proper milling operation for a …

How to Create Your Product Prototype

How to Create Your Product Prototype In this post, we’ll walk you through a step-by-step process for creating a product prototype. You’ll learn how to develop your ideas, find manufacturers, and even file for patents. And yes, you can do it. Your next step is to turn this rough idea into a functional prototype. We’ll share a process to create …

Why Every Engineer Should Be Using CAD

Why Every Engineer Should Be Using CAD CAD is an acronym for Computer-Aided Design. It refers to the method of using computer software to create virtual models of proposed products. There is a variety of CAD software available, each with special features that sometimes make the suitable for a particular application. Capabilities of CAD

Metal Surface Finishes

Below is some common metal surface finishes: Anodized Metals Machinists use this electrolytic passivation process to increase the thickness of the natural oxide layer on the surface of metals. Machinists anodize metals to increase their resistance to wear and corrosion. It also helps primers and glues adhere more easily to metal surfaces than ordinary metals do. If you anodized a …

Surface Finishes Basics

Surface Finishes Basics Metal surface finishing is essential in part production. No matter how good the finished part is, quality metal surface finishing can only make it better. Surface finishing is also referred to as surface texture, surface roughness, or surface topology. It is the process of altering a metal’s surface by adding, removing, or reshaping. Machinists use metal surface …

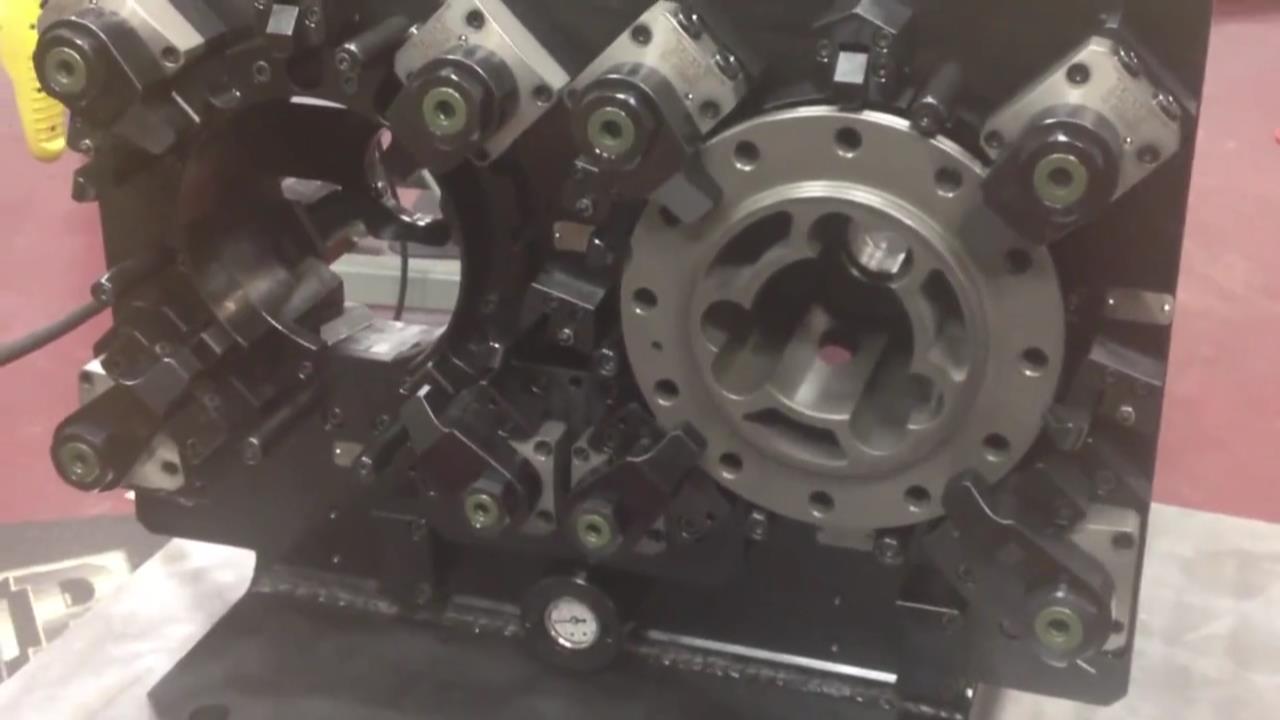

Seven Steps to Choosing the Right CNC Machine Tool

Mooming in a variety of different shapes, sizes, speeds, and other dimensions, CNC machine tools are the workhorses of the precision engineering and manufacturing industry. These indispensable machines on your shop floor have a wide variety of uses – from mold & die to fabricating complex medical, automobile, or aircraft parts, just to name a few. Equipped with varying degrees …

what is aluminum machining

Indeed, when used in machining, the different types of aluminum alloys possess some distinct and unique advantages. They come in a range of options which gives you huge flexibility when embarking on a machining project. However, narrowing the best aluminum alloy for the job also becomes harder. This guide attempts to provide a quick comparison of five of the most …

Aluminum material application

parts: aluminum 6061 CNC machining Aluminum is a relatively soft, durable, lightweight, ductile, and malleable metal with appearance ranging from silvery to dull gray, depending on the surface roughness. It is nonmagnetic and does not easily ignite. Aluminum is a tin-white metal which melts at 640 degrees and is very light, having a density of 2.68. It is stiff and …

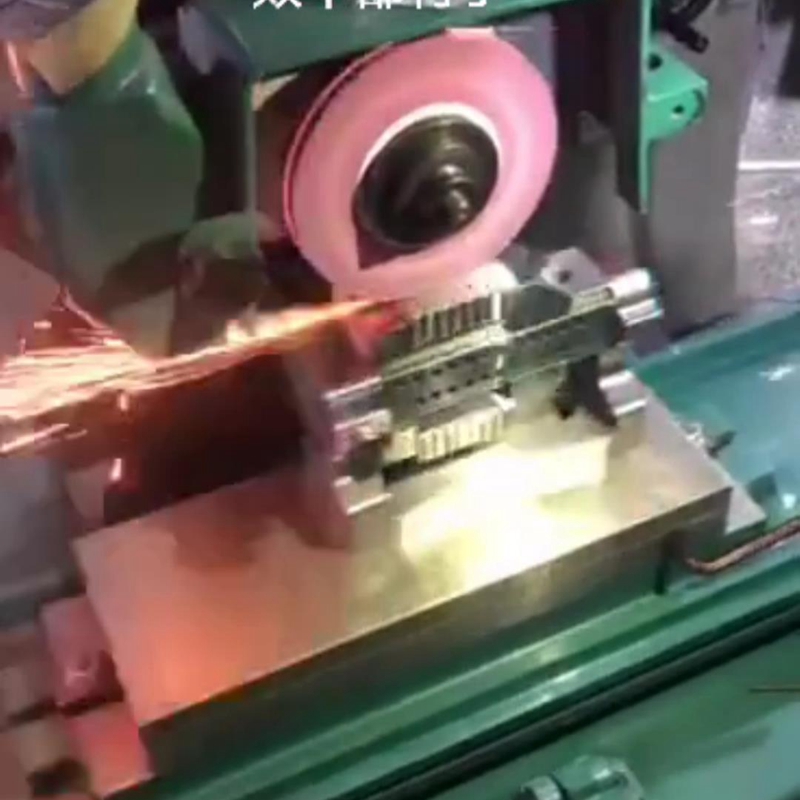

How to avoid deformation in CNC aluminum machining

Aluminum is an essential industrial material, but it has a major undoing. The alloys contain relatively low hardness and their thermal expansion are high, can deform when being machined into a thin part. However, several steps can be taken to avoid the deformation of the material beforehand. Symmetrical Machining It’s essential to avoid extreme concentration of heat but rather to …