Why Every Engineer Should Be Using CAD

March 16, 2023

Why Every Engineer Should Be Using CAD

CAD is an acronym for Computer-Aided Design. It refers to the method of using computer software to create virtual models of proposed products. There is a variety of CAD software available, each with special features that sometimes make the suitable for a particular application.

Capabilities of CAD

The design of a product must be ready down to the last detail before putting it into production. This ensures that no setbacks through necessary changes to the product can occur afterward.

Traditionally, doing this required manual drawing and designing using paper and pencil. Today, using CAD systems significantly reduces the amount of work. Creating 3D models and 2D drawings is faster and easier than ever before.

Although the projects can vary greatly, many of them still use a plethora of standard parts. For example, bolts, nuts, washers and other fasteners belong to the list of components when creating any kind of machinery.

In such cases, engineers can turn to part libraries to just pick the most suitable size for the application and use it in the assembly. This reduces time spent on creating small parts while making sure that fewer easy mistakes happen due to not displaying them in the model at all.

1.Rendered image

The parts and assemblies can be created, analyzed, improved and shared with others in CAD. You can apply colors, look at different angles and create rendered images for a life-like experience. This is especially common for displaying visuals for future products.

You can separate a large assembly into parts or display a predefined layer at a time. Many CAD programs have the essential tools of finite element analysis software. This helps to test the parts for force-bearing capabilities and dynamic loads.

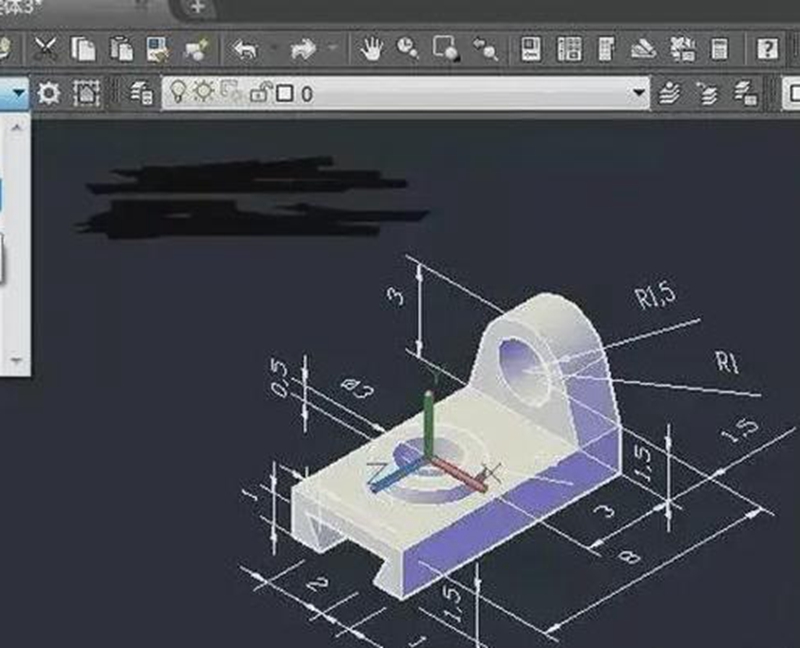

2. CAD can create 3D models

If you’ve ever tried to create a 3D model manually, you know how difficult and time-consuming a process it is.

A CAD 3D modeling package can take your 2D model and turn it into 3D quickly and easily. And if you’re going to be using 3D printing at any point during the product development process – say, for rapid prototyping – you have to have a CAD 3D model for the printer software to read.

3. CAD is easy to learn and use

You’d think that a computer program as complex as CAD would be a nightmare to learn, but that’s actually not the case. CAD is fairly easy to learn for engineers and product designers – in other words, for people who are used to thinking spatially and who have a background in design.

One of the best parts of CAD designing is that you have the same simple tools that we all use on our computers every day: cut, paste, copy, and delete. These have virtually no learning curve at all.

4. CAD designs can be replicated almost instantly

With CAD software, you can create as many copies of a design as you like. This is a huge advantage over manual drafting. If designs need to be shared with multiple departments, for example, or handed over to another product designer, being able to replicate your designs exactly is vitally important.

5. CAD designs can be modified quickly

Modifying a CAD design for, say, a second generation of a product, can be done quickly and easily. What’s more, all your modifications can be tracked and saved in the file. That means a lower chance of modifications being lost or forgotten.

Lost or unnoticed modifications can create huge costs and time disadvantages for companies, so any method that reduced the chance of this happening is something worth considering.

6. CAD files can be shared worldwide, instantly

In the global economy, the product development process can be distributed among different companies, some of which may be across the world from each other (unless you use an all-in-one product development partner).

Thus, a CAD system is much more than a replacement for manual drawings. It brings about a whole new level of possibilities that engineers can utilize for creating better products with fewer mistakes faster.

These values also align well with lean manufacturing methods and their principles of minimizing waste and maximizing productivity.

Advantages of CAD

CAD has a variety of advantages over manual drawings that have made it absolutely essential in the design market today. Let’s take a look at how they help contemporary engineers or product designers.

1. Saves Time

The ongoing era of product development entails a lot of competition. The time it takes to bring a product to market can be essential to its success.

With CAD, time is our lucrative reward. It saves the engineer a lot of work that can be put to good use on different projects or perfecting the design of the ongoing one. You can easily visualize the ideas you gathered during the product design concept generation phase.

Creating simple shapes and parts takes seconds. The biggest win, though, comes with more complex parts. For example, you can create a flat pattern of an intricate bent sheet metal part with a click of a mouse. No need to contemplate how to present it correctly.

At the same time, making changes is really easy. Or creating new models based on previous ones. You can just re-use a 3D model and add the necessary features to create a similar but unique part in a lot less time.

2. Increases Productivity

Time saved translates directly into augmented productivity. The same amount of time can result in a higher number of completed projects.

The repeatability of design is an option. Modifying the same design is possible to make infinite variations of the final product.

On average, a 3x increase in employee productivity is noticed. With time, this productivity can approach 10x. A large part of it comes down to the ability to create simulations in CAD rather than doing manual calculations.

This improvement is seen on multiple fronts like quality, time, and cost reduction in manufacturing.

3. Improves Accuracy

Manual sketching cannot measure up to the accuracy of CAD drawings. CAD design’s accuracy is unparalleled with almost no errors. This gives it a huge advantage over manual designing and drafting.

Of course, the designer must still pay attention to the outcome. The “retrieve dimensions” function does not replace an engineer, as it does not recognize the base planes for measurements, for example. And this can be crucial with parts like shafts.

Complex surfaces and shapes can be created comparatively easily in CAD. These surfaces are extremely difficult to get right with manual sketching but with CAD systems’ tools, a perfect result can be obtained.