Why Every Engineer Should Be Using CAD

Why Every Engineer Should Be Using CAD CAD is an acronym for Computer-Aided Design. It refers to the method of using computer software to create virtual models of proposed products. There is a variety of CAD software available, each with special features that sometimes make the suitable for a particular application. Capabilities of CAD

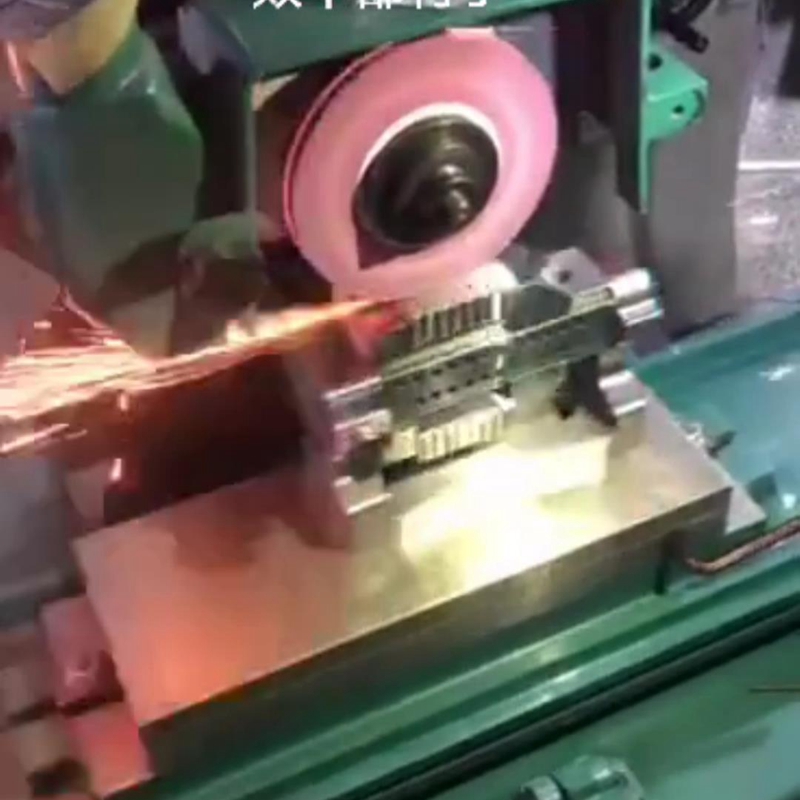

Surface Finishes Basics

Surface Finishes Basics Metal surface finishing is essential in part production. No matter how good the finished part is, quality metal surface finishing can only make it better. Surface finishing is also referred to as surface texture, surface roughness, or surface topology. It is the process of altering a metal’s surface by adding, removing, or reshaping. Machinists use metal surface …

Various Aluminum Alloy For Manufacturing

Often chosen for its weight-to-strength ratio, aluminum is one of the most abundant and versatile metals used in manufacturing. In most manufacturing applications, different types of aluminum alloys are chosen because their properties are well-suited to the manufacturing process or the end-use of a component or structure. Aluminum alloys are produced by adding elements such as zinc, copper, magnesium, manganese, …

GPT precision manufacturing shop It is worth to remember

Workpiece-tool interaction, when machining aluminum cast alloys results in an abrasive flank wear, influences the shape and the dimensional accuracy as well as the surface integrity of the work piece. Cutting forces in the machining of aluminum alloys are usually low compared to those of ferrous alloys due to their lower mechanical strength, which may generate 70 % lower specific …

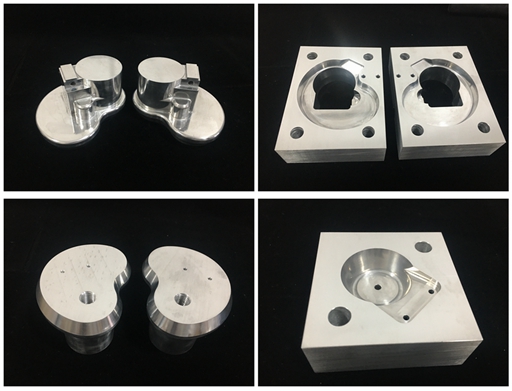

About CNC Machined Aluminium

A CNC machine runs on a computer program; it can either be for prototyping or in full item production. Aluminum is the commonly machined material, as it exhibits excellent machinability, and is thus the preferred material in the most manufacturing sector. Aluminum as a material offers some interesting thermal and mechanical properties. Besides, the aluminum metal is relatively easy to …

CNC Machining Vs Die Casting – Which Is Better?

Two of the most popular industrial processes for creating metal parts are die casting and CNC machining. Both processes can even be combined for the best possible finish. However, when it comes to choosing one process over the other, there are several important factors to consider. Two of the most popular industrial processes for creating metal parts are die casting …

How can you improve the machinability of Aluminium

The machine-friendliness of aluminum has made it the number one metal for machining. Its material properties make it easy to mill, drill, cut and punch, while aluminum machined parts can be strong, durable and aesthetically pleasing. All in all, aluminum is the most machinable metal on the market. Despite this, aluminum is far from perfect. Its easy machinability is counteracted …

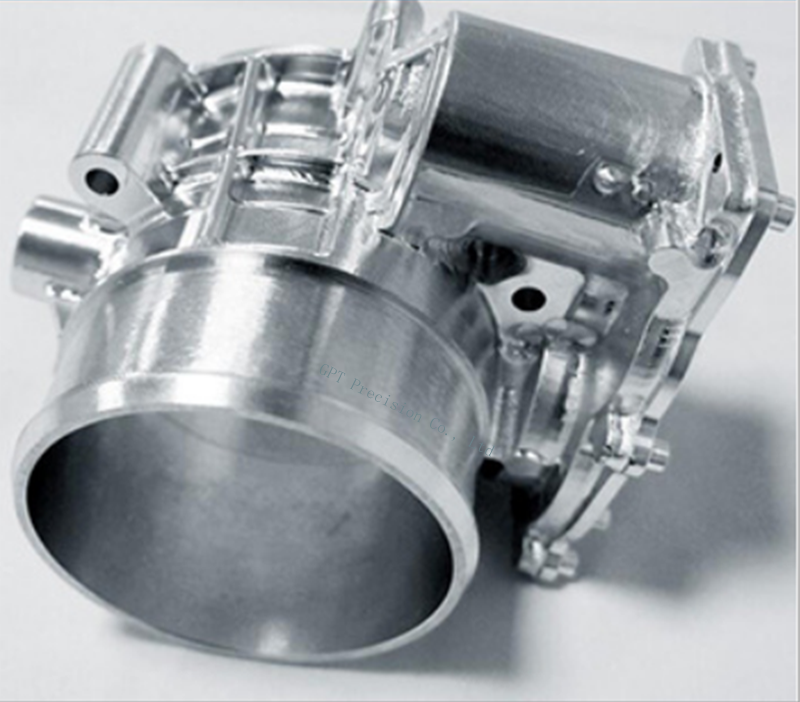

OEM Precision Aluminum Cnc Machining Parts Service

GPT Precision has more than decades of experience in CNC manufacturing services in China and can offer one-stop service (CNC machining parts & CNC machining prototype) for our OEM customers. All processes are carried out through hundreds of advanced CNC Machining machines, lathes, and other manufacturing facilities, ranging from blasters to Ultra Sonic washing machines. GPT Precision CNC Machining Center …

WHAT’S THE DIFFERENCE BETWEEN 3-AXIS, 4-AXIS & 5-AXIS MILLING?

At GPT Precision, we have a range of state of the art 3-axis, 4-axis and 5-axis milling machines. As a designer, having an understanding of which type of machine your part will be manufactured on is critical in optimising your design. When designing a CNC machined part, you might not have thought about which type of machine your part will …

HOW TO CHOOSE THE PERFECT CNC MACHINE FOR YOUR PRODUCTION

Machine centers are known for their high precision, high reliability, high efficiency, and the ability to machining complex workpieces. However, if the selection is not thought of thoroughly, you will not be able to exert its due benefits, and with the high cost of the machining centers now a days, you really want to guaranty your ROI (return of investment). …

When to avoid CNC machining

When to avoid CNC machining Our advice on when to choose CNC machining should give you a fairly good idea of when to avoid CNC machining. The limitations of the process making it less desirable in situations when complex geometries are required, or when extreme order quantities are needed. The turnaround can also be a factor: if a part is …

Application of precision aluminum products

Aluminum alloys are a common material used for investment casting, and cast aluminum parts can be post-machined and given a coating for refinement. What is aluminum parts Machining? Aluminum is one of the most popular machining materials thanks to its workability, strength, and versatility. What’s more, its low cost makes it perfect for prototypes, end-use products, and custom tools for …