CNC Milling vs CNC Turning-The Differences

CNC Milling vs CNC Turning-The Differences Before we go on to discuss the difference between CNC milling and CNC turning, let’s define what CNC milling is. A CNC machine works towards producing a finished product through an automated process, receiving commands from a computer with pre-programmed software. What is CNC milling? Turning is a process in which a workpiece rotates …

Why Every Engineer Should Be Using CAD

Why Every Engineer Should Be Using CAD CAD is an acronym for Computer-Aided Design. It refers to the method of using computer software to create virtual models of proposed products. There is a variety of CAD software available, each with special features that sometimes make the suitable for a particular application. Capabilities of CAD

Surface Finishes Basics

Surface Finishes Basics Metal surface finishing is essential in part production. No matter how good the finished part is, quality metal surface finishing can only make it better. Surface finishing is also referred to as surface texture, surface roughness, or surface topology. It is the process of altering a metal’s surface by adding, removing, or reshaping. Machinists use metal surface …

Various Aluminum Alloy For Manufacturing

Often chosen for its weight-to-strength ratio, aluminum is one of the most abundant and versatile metals used in manufacturing. In most manufacturing applications, different types of aluminum alloys are chosen because their properties are well-suited to the manufacturing process or the end-use of a component or structure. Aluminum alloys are produced by adding elements such as zinc, copper, magnesium, manganese, …

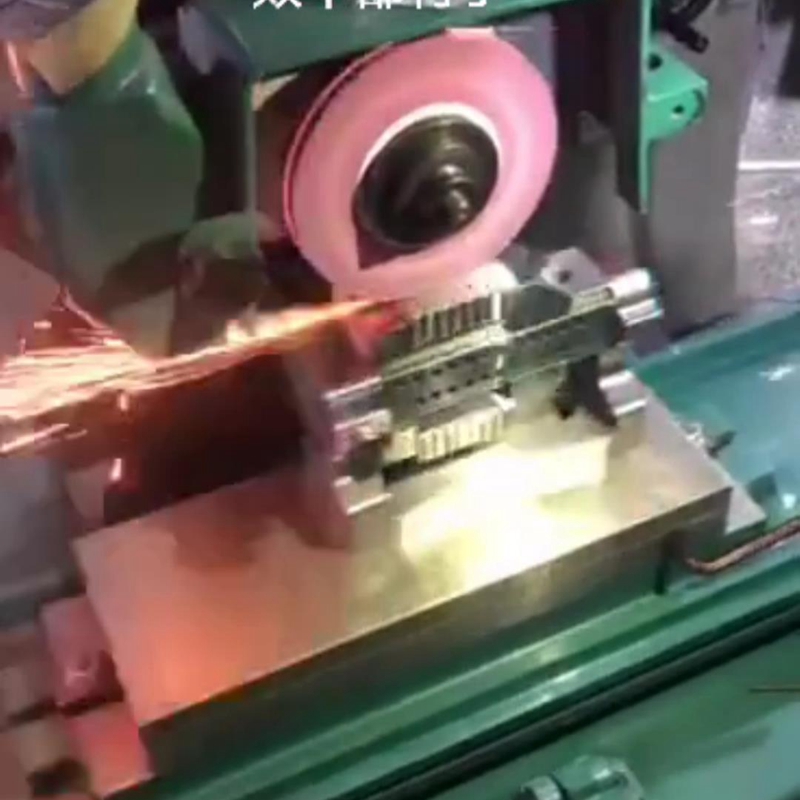

What is CNC Turning?

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret (shown center), with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result. This …

CNC Milling vs. CNC Turning

CNC machining service come in different shapes and forms. This article explains the difference between CNC machining and CNC turning, two common CNC technologies. CNC machining is a rapid manufacturing process that turns digital 3D designs into plastic or metal parts by selectively cutting away material. Many companies require CNC machining services to make parts and prototypes, and many industries …

The Applications of CNC Machining

Everyone involved in manufacturing should take advantage of what this technology can do for their company. For instance, CNC machines:Have a high degree of automation that lowers a company’s labour intensity;Achieve a more precise level of production that produces good product consistency exponentially faster;Have a multi-axis linkage that allows you to attain complex processing of the prototype machining. So, what …

WHAT’S THE DIFFERENCE BETWEEN 3-AXIS, 4-AXIS & 5-AXIS MILLING?

At GPT Precision, we have a range of state of the art 3-axis, 4-axis and 5-axis milling machines. As a designer, having an understanding of which type of machine your part will be manufactured on is critical in optimising your design. When designing a CNC machined part, you might not have thought about which type of machine your part will …

What is CNC Bending?

Computer numerically controlled (CNC) bending is a manufacturing process that is carried out by CNC press brakes (also known as CNC brake presses). These machines can bend sheet metal work from just a few mm across to sections many metres long on the largest industrial machines. CNC press brakes either have a fixed bottom bed with the V block tooling …

What Is CNC?

CNC stands for Computer Numerical Control is an automated control of machining tools such as; drills, lathes, mills, and 3D printers using a computer. It takes digitized data and is controlled, automated and monitored by a computer and CAM (Computer-Aided Manufacturing) program. CNC machines are fully automated, needing only digital files with instructions about cutting trajectories and tooling. It is …

When Should You Choose CNC Machining?

When Should You Choose CNC Machining? CNC machining is a hugely versatile and reliable manufacturing process used for a variety of applications. Whether for prototyping or production, metals or plastics, CNC machining is an essential tool for engineers in manufacturing, automotive, aerospace, medicine, consumer products, and many other industries. But that doesn’t make CNC an automatic choice for all projects. …

WHAT IS PRECISION MACHINING USED FOR?

Precision machining is a subtractive process used in cases where material needs to be removed from a raw product to create the finished product. Precision machining can be used to create a wide variety of products, items, and parts for any number of different objects and materials. These parts usually require tight tolerances variation from nominal dimensions and from part …