Types of CNC Milling Operations

Types of CNC Milling Operations Various types of CNC milling operations are designed to achieve specific outcomes depending on the material type. These operations differ in the type of cutting tool used, the cut’s direction, the cut, the depth of the cut, the speed & feed rate, and other machining parameters. In addition, choosing the proper milling operation for a …

How To Determine The Accuracy Of Your CNC Machine Shop

How To Determine The Accuracy Of Your CNC Machine Shop The quality of CNC machined parts depends on many factors, including part design, tool selection, tool path programming, machinist skill set, workpiece clamping strategy, etc. Critical path functional components, such as robotic arms for laser surgery or landing gear components of high-performance aircraft, must operate reliably. Reliability requires accuracy, precision, …

Metal Surface Finishes

Below is some common metal surface finishes: Anodized Metals Machinists use this electrolytic passivation process to increase the thickness of the natural oxide layer on the surface of metals. Machinists anodize metals to increase their resistance to wear and corrosion. It also helps primers and glues adhere more easily to metal surfaces than ordinary metals do. If you anodized a …

Seven Steps to Choosing the Right CNC Machine Tool

Mooming in a variety of different shapes, sizes, speeds, and other dimensions, CNC machine tools are the workhorses of the precision engineering and manufacturing industry. These indispensable machines on your shop floor have a wide variety of uses – from mold & die to fabricating complex medical, automobile, or aircraft parts, just to name a few. Equipped with varying degrees …

GPT precision manufacturing shop It is worth to remember

Workpiece-tool interaction, when machining aluminum cast alloys results in an abrasive flank wear, influences the shape and the dimensional accuracy as well as the surface integrity of the work piece. Cutting forces in the machining of aluminum alloys are usually low compared to those of ferrous alloys due to their lower mechanical strength, which may generate 70 % lower specific …

What Are the Basics of CNC Milling and Turning?

Computer Numerical Control (CNC) technology has dominated the metal forming industry in recent years, as it offers advanced precision and repeatability that can be impossible to achieve with manual processes alone. With so many CNC technologies on the market, it can be difficult to distinguish between them and what they are used for. While there are many similarities between CNC …

HOW TO CHOOSE THE PERFECT CNC MACHINE FOR YOUR PRODUCTION

Machine centers are known for their high precision, high reliability, high efficiency, and the ability to machining complex workpieces. However, if the selection is not thought of thoroughly, you will not be able to exert its due benefits, and with the high cost of the machining centers now a days, you really want to guaranty your ROI (return of investment). …

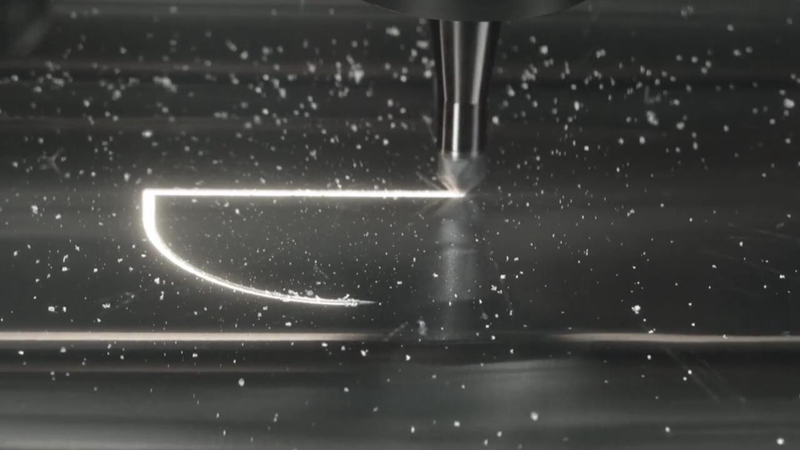

milling Machining components

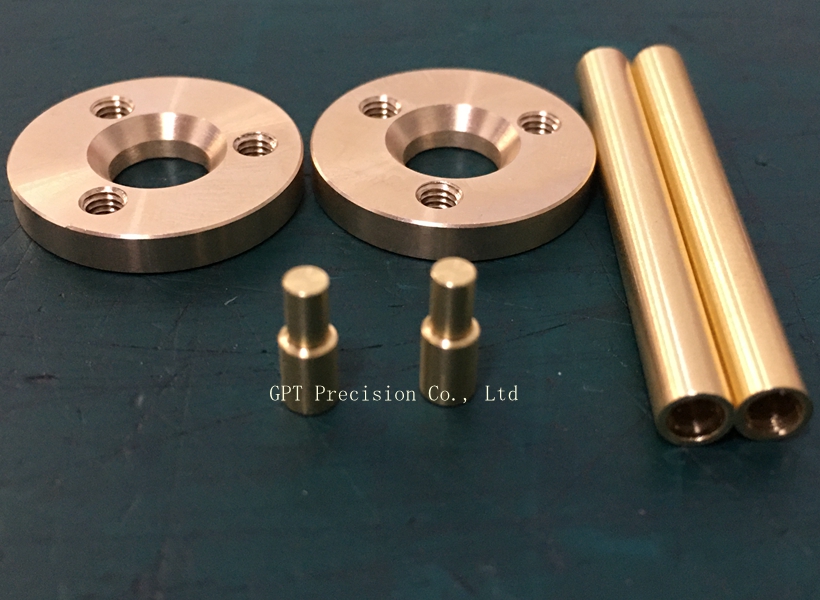

GPT Precision Co., Ltd provides a comprehensive and high-quality CNC milling service from a 1200 square meter specialist machining facility in Shenzhen, China. CNC milling parts CNC machined components are the most commonly used machining process.It is the process that removes the material from a workpiece by using rotary cutters.CNC milling machines are often classified by the number of axes …

CNC milling services

CNC Machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers and grinders. The CNC in CNC Machining stands for Computer Numerical Control. Under CNC Machining, machine tools function through numerical control. A computer program is customized for an …

CNC Machining China components

CNC milling is used to apply a machined surface finish on plastic or metal or for creating complex 3D shapes. Looking something like a drill press, a milling machine uses a cutting tool that moves in all three dimensions, removing material to achieve the desired part shape , A block of material is placed on a moving table below the …