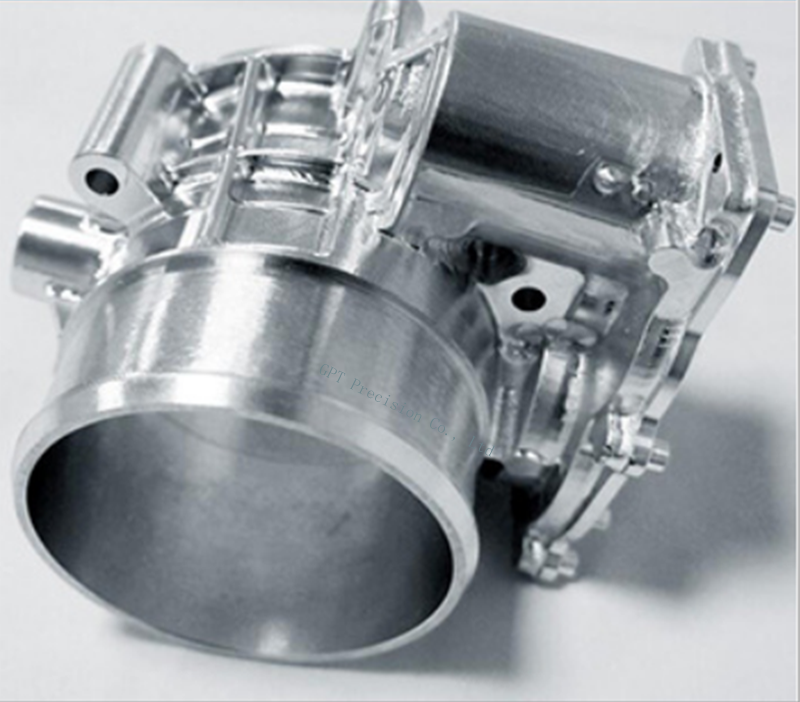

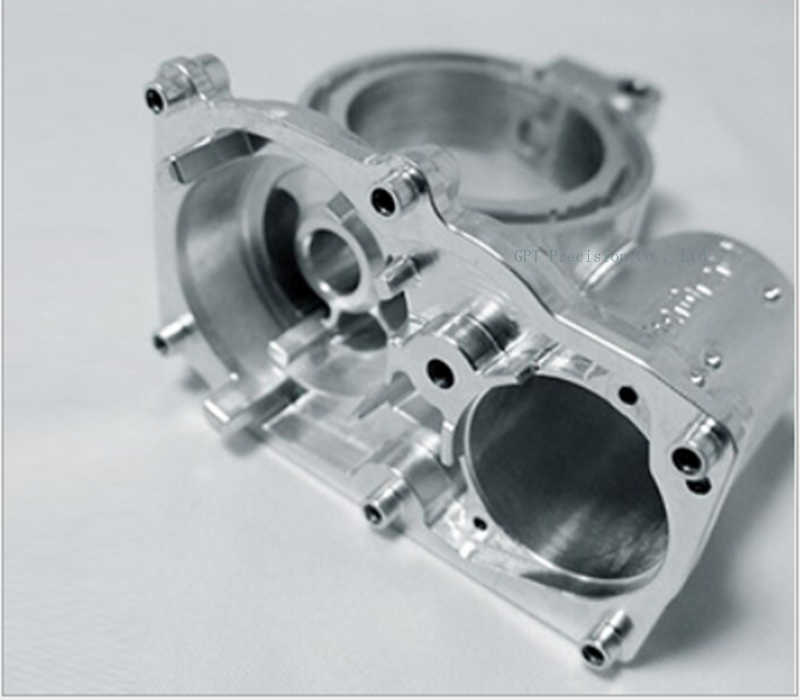

Application of precision aluminum products

Application of precision aluminum products

Port: Shenzhen China

Production Capacity:20000

Payment Terms:L/C, T/T, Western Union

Shaping Mode: CNC professional turning,milling,drilling

Surface treatment: Polishing, Anodizing, Painting, Silk Print, etc

Material: Stainless steel, mald steel ,zinc alloy ,aluminium alloy,brass ,bronze ,copper ,etc.

Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Specifications

Aluminum alloys are a common material used for investment casting, and cast aluminum parts can be post-machined and given a coating for refinement.

What is aluminum parts Machining?

Aluminum is one of the most popular machining materials thanks to its workability, strength, and versatility. What’s more, its low cost makes it perfect for prototypes, end-use products, and custom tools for molding. From standard grades like 6061 to high-quality aerospace grades like 7075, we have an aluminum alloy for every CNC machining project.

We also have the skills and the cutting-edge equipment to handle every challenge that might arise during production and improve the machinability of aluminum compared to our competitors. Our team has years of experience in machining with complex aluminum machined, as it makes up roughly 60% of used materials.

Our in-house equipment includes HAAS 5-axis mills with edge finding equipment, Hexagon CMMs, Olympus XRF analyzers, and a range of cutting tools for efficient chip removal. We machine at a fast rate, offering fast speeds and excellent material properties from your CAD files. With the help of our cutting-edge equipment, we can avoid aluminum part deformation and produce consistent results for our clients.

Industries using CNC Machined Aluminum Parts

Aerospace: due to its high strength to weight ratio, several aircraft fittings are made from machined aluminum;

Automotive: similar to the aerospace industry, several parts such as shafts and other components in the automotive industry are made from aluminum;

Electrical: having high electrical conductivities, CNC precision machining aluminum parts are often used as electronic components in electrical appliances;

Food/Pharmaceutical: because they do not react with most organic substances, aluminum parts play important roles in the food and pharmaceutical industries;

Sports: aluminum is often used to make sports equipment such as baseball bats and sport whistles;

Cryogenics: aluminum’s ability to retain its mechanical properties at sub-zero temperatures, makes aluminum parts desirable for cryogenic applications.

In Summary

Aluminum is a versatile material with a high level of machinability. We have a full understanding of its capabilities and machining requirements. Use our inquiry form if you require CNC Machining or contact us for any questions that you may have.

We can machine aluminum using several CNC machining processes available today. customized aluminum parts processes are as follows.

Turning

In CNC precision turning operations, the workpiece rotates, while the single-point cutting tool stays stationary along its axis. Depending on the machine, either the workpiece or the cutting tool carries outfeed motion against the other in order to achieve material removal.

Milling

Milling operations are perhaps the most commonly used in CNC machining aluminum parts. These operations involve the rotation of a multi-point cutting along its axis, while the workpiece stays stationary along its own axis.

Cutting action and subsequently, material removal is achieved by the feed motion of either the workpiece, the cutting tool, or both of them combined. This motion can be carried out along multiple axes.

Pocketing

Also known as pocket milling, pocketing is a form of CNC milling in which a hollow pocket is machined in a part.

Facing

Facing in machining involves creating a flat cross-sectional area on the surface of a workpiece through either face turning or face milling.

Drilling

Drilling is the process of making a hole in a workpiece. In this operation, a multi-point rotating cutting tool of a particular size moves in a straight line perpendicular to the surface to be drilled, thereby effectively creating a hole.