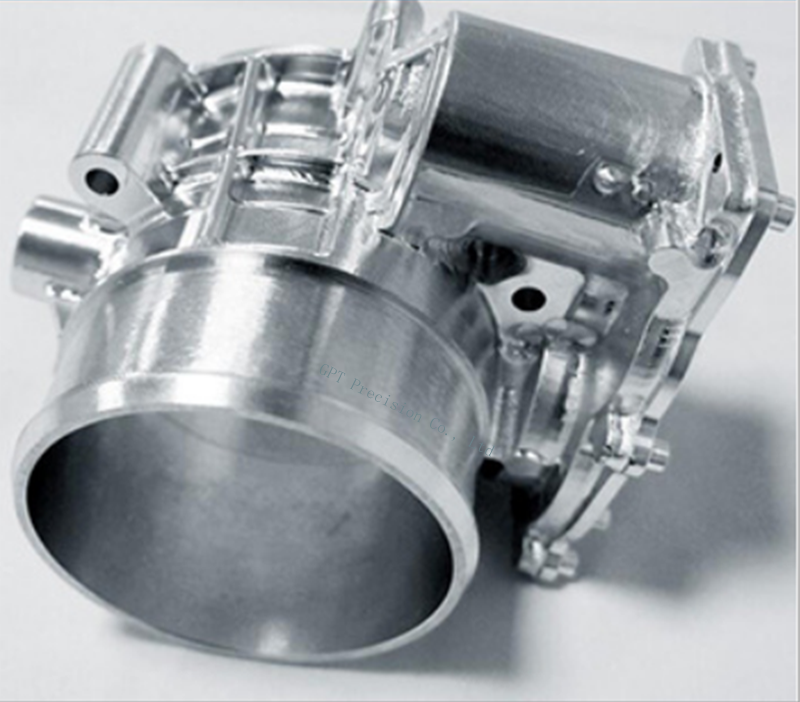

CNC Machined Manufacturing Technique

Port: Shenzhen, China

Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram

Application: Auto and Motorcycle Accessory, Machinery Accessory, Medical

Standard: GB, JIS Code, TEMA, ASME

Surface Treatment: Zinc plating, chrome palting ,nickel plating ,painting ,sand blasting ,powder coating ,polishing ,anodized ,baking finish ,oxidation ,electroplate ,passivate.

Production Type: Batch Production

Machining Method: CNC Machining

Material: Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, Nylon

- Specifications

Angular Milling: also written a angle milling, milling flat surfaces which are neither parallel nor perpendicular to the axis of the cutter.

Gear Milling: the milling process for creating a gear.

Thread Milling: the interpolation of a thread mill around or inside a workpiece to create a desired thread, requires machines capable of moving on the X, Y, and Z axis simultaneously.

Profile Milling: rough or finish mill vertical or slanted surfaces, continuous tool path.

Straddle Milling: machine two or more parallel vertical surfaces at a single cut.

Other milling operations: Gang Milling, Side Milling, End Milling, Saw Milling, Helical Milling, Cam Milling, Milling Keyways, Grooves and Slot.

Plain Milling: also called surface or slab milling, refers to the milling operation utilize plain milling cutters with teeth on the periphery to perform the cutting, the axis of rotation of the cutting tool is parallel to the workpiece surface.

Face Milling: the operation use milling cutters have teeth both on the periphery and tool face, the rotating axis of cutting tool is perpendicular to the surface of the workpiece,generally for producing flat surfaces and contours.

Form Milling: uses form cutting tools or fly cutters for specific purposes, including convex, concave cutters, typically for creating irregular surfaces and contours like curved surfaces.

CNC Milling Machines – What Is A CNC Mill & Types of Milling Machines

CNC milling machine employs a rotating cylindrical tool (milling cutter) held in a spindle to perform the milling operations, for getting a wide array of shapes, slots, holes, and other necessary impressions. As a common Computer Numerical Control machine, CNC mill has the ability to cut in different angles and move along several axes, allows a variety of milling parts features and designs. The workpiece on CNC mill can be moved across the tool in certain direction.

There are different types of CNC mills divided according to the number of axes:

2-axis CNC milling machine: cut holes and slots in the x- and z-axes

3-axis CNC milling machines: added y-axis, can cut vertically and in any direction

4-axis CNC milling machines: add the ability to rotate the x-axis, similar to a lathe.

5-axis CNC milling machines: most complete milling machine, incorporate rotation in both the x- and y-axes.