News

Read company news,machining news,components making process informational articles, guides & tips, Learn about the manufacturing world in China

TOOLS OF CNC MILL

CNC tools come in nearly as many varieties as products created by the milling process. Understanding the uses of these tools will make it easier to choose the ones you need for your project. Selecting the right tools makes the process of CNC machining more accurate. 1. End mill The end mill is the most widely used tool for vertical …

The Applications of CNC Machining

Everyone involved in manufacturing should take advantage of what this technology can do for their company. For instance, CNC machines:Have a high degree of automation that lowers a company’s labour intensity;Achieve a more precise level of production that produces good product consistency exponentially faster;Have a multi-axis linkage that allows you to attain complex processing of the prototype machining. So, what …

Affects the Machinability of Aluminum

Metallurgical Structure Affects the Machinability of Aluminum Advancements in grain structure consistency and mechanical properties help to make this extremely machinable metal suitable for an ever growing range of applications. The term “machinability” refers to the ease with which a metal can be machined to an acceptable surface finish. But maximizing machinability is a complex, sometimes trial-and-error process that is …

Medical Device Prototyping

At GPT precision, we offer reliable rapid prototyping and rapid manufacturing solutions crafted to suit the needs of the medical devices industry. Regardless of our project load, our customers can rest assured that we will deliver high quality, precision products on time and at affordable rates. The Medical Prototyping Process The medical device prototyping process consists of four key stages: …

Rapid Manufacturing on Demand

Within the medical industry, prototyping is a critical step in the time-, cost-, and labor-intensive process of launching a new product. The medical device prototyping process produces functional samples to exact design and material specifications for use in product testing and evaluation stages and business presentations. These samples enable manufacturers to verify the efficacy and manufacturability of the design and …

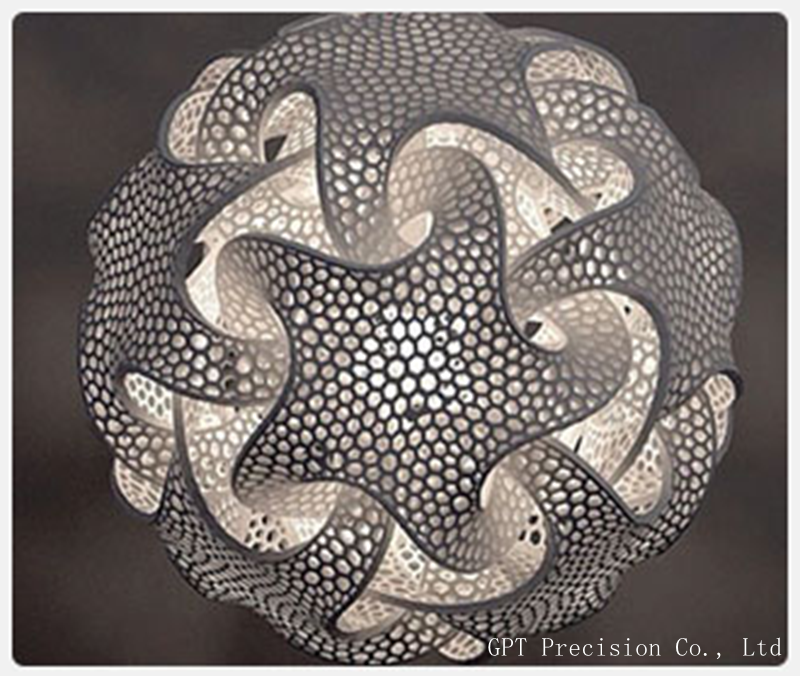

3D Printing (additive manufacturing) Techniques for Medical Device

Additive manufacturing is the ideal way to create medical products. A variety of production processes allow you to design parts with internal tubes, channels, curves, and other features that are impossible to create with traditional machining or molding. 3D printing is a great way to create one-off parts or small batches, and can be used to create complex geometries that …

CNC vs. 3D Printing: What’s the Best Way to Make Your Part?

3D printing is a rapidly growing technology with many advantages over traditional manufacturing methods. It however has its problems, including that 3D printing cannot be effectively used for mass production, and is limited in speed and accessibility. Another manufacturing technique for low-to-mid production is CNC machining (computer numerical control), a fairly common subtractive technique for part creation. We decided to …

CNC Milling & Aluminum Heat Treatment

Part of the designing and engineering process is to determine what physical properties the part needs and the best metal chose to provide those requirements. Having metal alloys heat treated, either before or after machining, can immensely improve key physical properties. Heating treatments can add to the hardness of the metal, its strength, or its machinability. When are heat treatments …

OEM Precision Aluminum Cnc Machining Parts Service

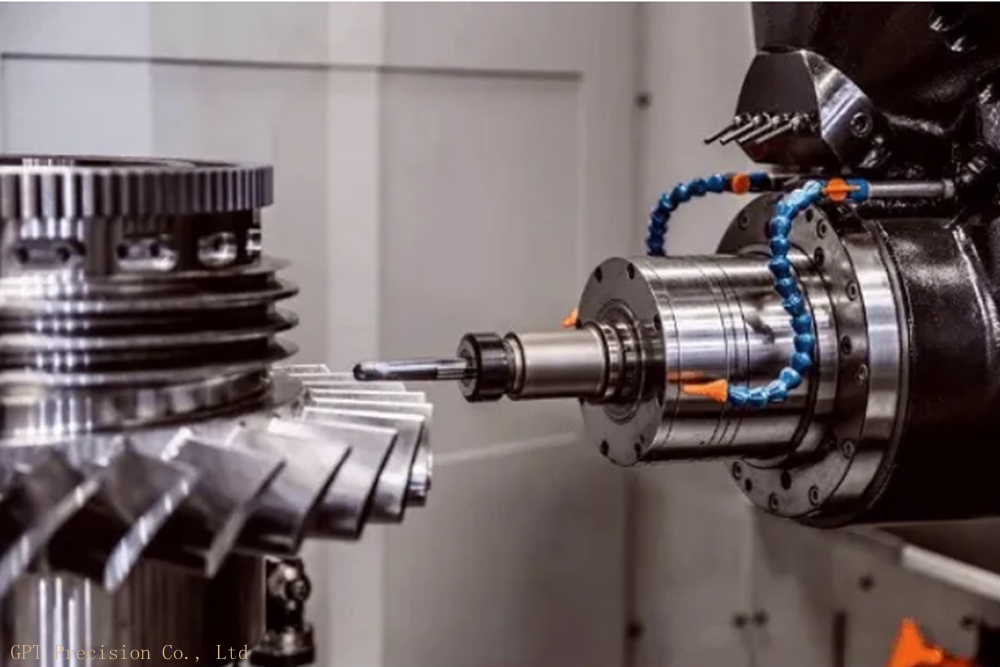

GPT Precision has more than decades of experience in CNC manufacturing services in China and can offer one-stop service (CNC machining parts & CNC machining prototype) for our OEM customers. All processes are carried out through hundreds of advanced CNC Machining machines, lathes, and other manufacturing facilities, ranging from blasters to Ultra Sonic washing machines. GPT Precision CNC Machining Center …

How To Carry Out Precision CNC Machining?

Precision CNC machining is a general term used for a variety of machining applications. “CNC” stands for Computer Numerical Controlled and refers to the programmable feature of the machine, allowing the machine to perform many functions with minimal human control. Precision CNC machining is the fabrication of a component using a CNC controlled machine. The term describes a range of …

WHAT’S THE DIFFERENCE BETWEEN 3-AXIS, 4-AXIS & 5-AXIS MILLING?

At GPT Precision, we have a range of state of the art 3-axis, 4-axis and 5-axis milling machines. As a designer, having an understanding of which type of machine your part will be manufactured on is critical in optimising your design. When designing a CNC machined part, you might not have thought about which type of machine your part will …

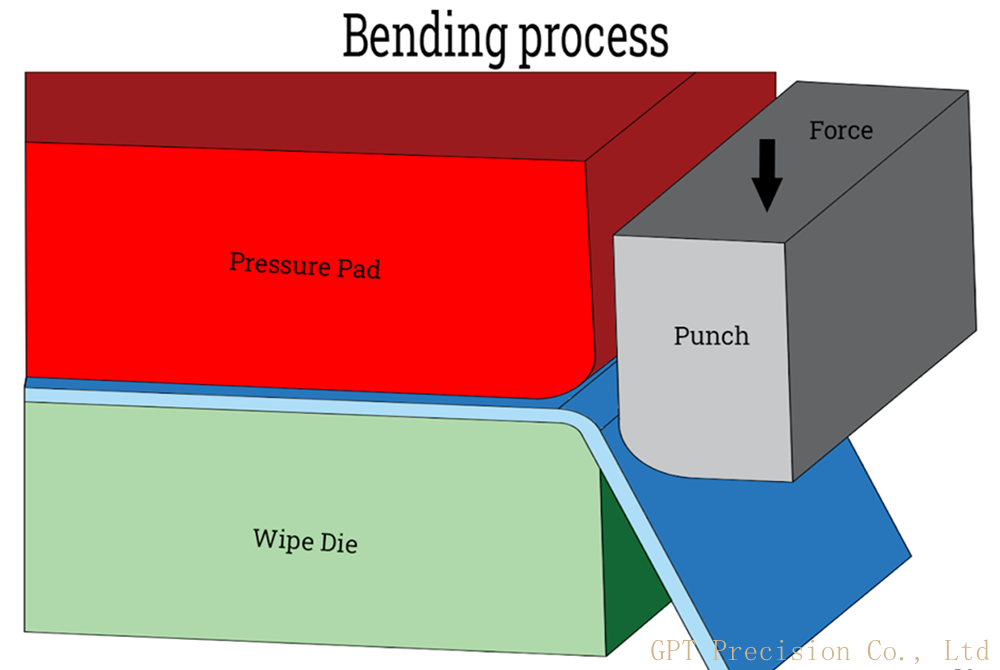

How Does Sheet Metal Fabrication Work?

illustration of sheet metal process During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry, a sheet metal punch (2) can form additional features. Once the parts are deburred, they move to the press brake (3) where they are formed …