News

Read company news,machining news,components making process informational articles, guides & tips, Learn about the manufacturing world in China

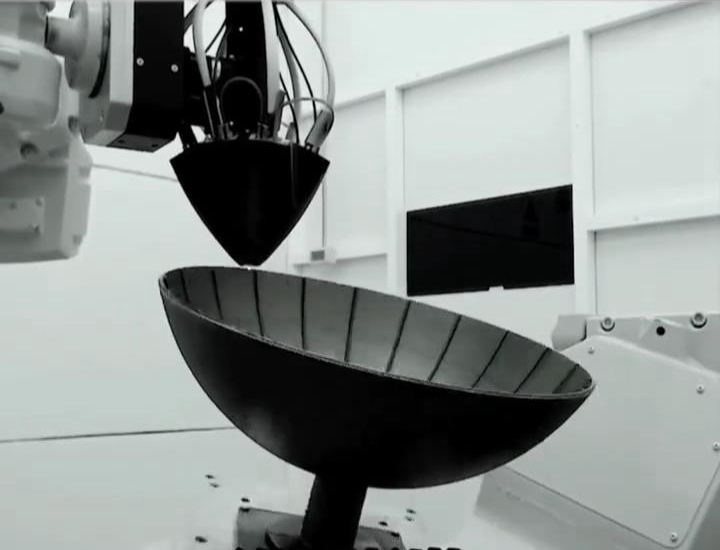

3D Printing vs CNC Machining

3D printing is a rapidly growing technology with many advantages over traditional manufacturing methods. It however has its problems, including that 3D printing cannot be effectively used for mass production, and is limited in speed and accessibility. Another manufacturing technique for low-to-mid production is CNC machining (computer numerical control), a fairly common subtractive technique for part creation. We decided to …

What Should I Do When My Rapid Prototypes Don’t Work?

What Should I Do When My Rapid Prototypes Don’t Work? Bringing a great idea to reality means you need to take a number of works starting from 3D model building to prototype manufacturing then functional verification. If the idea can’t go through the rapid prototypes stage, the product/idea has no chance to present and show in public, which means your …

How To Determine The Accuracy Of Your CNC Machine Shop

How To Determine The Accuracy Of Your CNC Machine Shop The quality of CNC machined parts depends on many factors, including part design, tool selection, tool path programming, machinist skill set, workpiece clamping strategy, etc. Critical path functional components, such as robotic arms for laser surgery or landing gear components of high-performance aircraft, must operate reliably. Reliability requires accuracy, precision, …

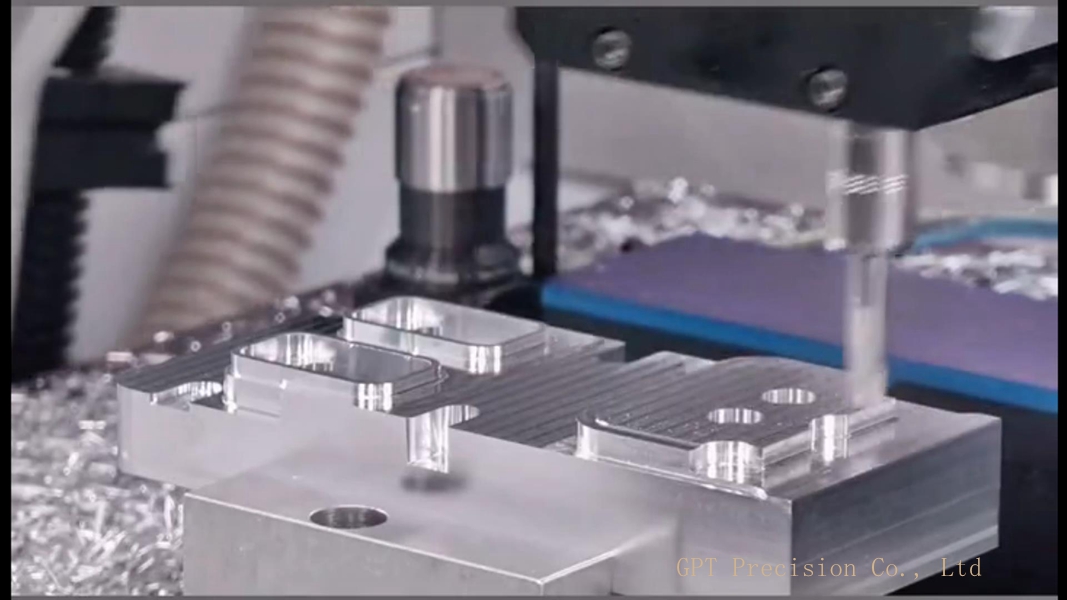

CNC prototyping cost drivers

In the following article, we’ll break down the costs associated with CNC prototyping, showing you exactly where cost matters and where costs can be reduced. A skilled manufacturing service such as GPT Precision Co., Ltd understands the ins and outs of CNC prototyping and can therefore deliver high-quality parts at competitive costs. The first thing to realize is that the …

Various Aluminum Alloy For Manufacturing

Often chosen for its weight-to-strength ratio, aluminum is one of the most abundant and versatile metals used in manufacturing. In most manufacturing applications, different types of aluminum alloys are chosen because their properties are well-suited to the manufacturing process or the end-use of a component or structure. Aluminum alloys are produced by adding elements such as zinc, copper, magnesium, manganese, …

About the Aluminum material

Aluminum is one of the most commonly used metals in the world because of its excellent strength-to-weight ratio, low cost, and recyclability. GPT precision offers multiple aluminum alloys parts. Our standard alloy on platform is 6061, a versatile and easy-to-machine metal. It is corrosion-resistant, non-magnetic, and heat treatable. 7075 Aluminum is a hard, high strength alternative to 6061 Aluminum . …

GPT precision manufacturing shop It is worth to remember

Workpiece-tool interaction, when machining aluminum cast alloys results in an abrasive flank wear, influences the shape and the dimensional accuracy as well as the surface integrity of the work piece. Cutting forces in the machining of aluminum alloys are usually low compared to those of ferrous alloys due to their lower mechanical strength, which may generate 70 % lower specific …

About CNC Machined Aluminium

A CNC machine runs on a computer program; it can either be for prototyping or in full item production. Aluminum is the commonly machined material, as it exhibits excellent machinability, and is thus the preferred material in the most manufacturing sector. Aluminum as a material offers some interesting thermal and mechanical properties. Besides, the aluminum metal is relatively easy to …

Types of Lathes Simplified

Lathe machines are machines used for shaping various types of workpieces, but they don’t come one size fits all. There are many types of lathe and which one you need will depend on the material you are shaping and your specific requirements. For those who are looking to clarify the differences of lathe machines, look no further. This guide will …

CNC Turning Center Basics

What is a CNC Turning Center? (Centre) CNC turning centers are advanced computer numerically controlled machines. They can have 3, 4, or even 5 axes, along with a multitude of cutting capabilities, including milling, drilling, tapping, and ofcourse, turning. Often these machines have an enclosed setup to ensure any cut material, coolant, and components remain within the machine. What is …

CNC Milling vs. CNC Turning

CNC machining service come in different shapes and forms. This article explains the difference between CNC machining and CNC turning, two common CNC technologies. CNC machining is a rapid manufacturing process that turns digital 3D designs into plastic or metal parts by selectively cutting away material. Many companies require CNC machining services to make parts and prototypes, and many industries …

Application Of CNC Milling

The CNC machining quality is stable, the machining accuracy is high, and the repeat accuracy is high. Under the conditions of multi-variety and small batch production, CNC machining has high production efficiency, which can reduce the time of production preparation, machine tool adjustment and process inspection, and reduce the cutting time due to good use and cutting volume. Milling is …