How to Create Your Product Prototype

April 20, 2023

How to Create Your Product Prototype

In this post, we’ll walk you through a step-by-step process for creating a product prototype. You’ll learn how to develop your ideas, find manufacturers, and even file for patents. And yes, you can do it.

Your next step is to turn this rough idea into a functional prototype. We’ll share a process to create your own prototype below:

1. Create a detailed diagram or sketch

The first step in creating a prototype is to create a detailed concept sketch or diagram. Your objective should be to capture as many ideas as possible in a visual manner.

Ideally, you should have two concept sketches:

A design sketch showing how the product might appear upon completion

A technical sketch showing the product’s dimensions, materials, and working.

You can use software to do this, but pen and paper work better. You can even turn to these pen and paper drawings when you’re filing a patent. Feel free to experiment and be creative in this step. You’re a long way from manufacturing at this point; don’t be afraid to try new things.

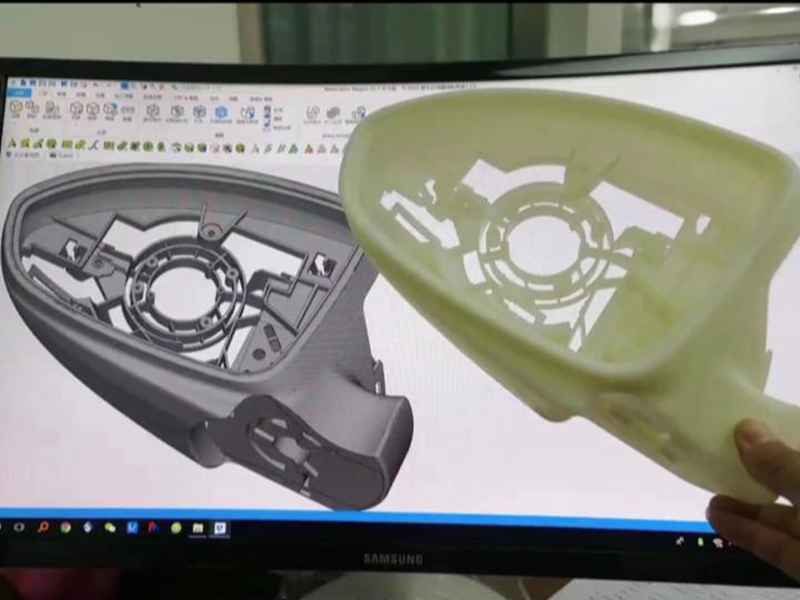

2. Create a 3D model (optional)

The next (optional) step is to transfer your concept sketches to 3D modeling software. This will help you (and any third-parties such as investors or partners) visualize the product better. You can also use this model to create a 3D-printed copy of your prototype.

Another benefit of a 3D model is that you can use augmented reality apps such as Precisiontoolingchina.com to visualize it in the real world. This works particularly well to demonstrate the size, shape, and design of a product idea. It can be expensive for a small business that hasn’t launched yet, though.

3. Create a “proof of concept”

Now comes the fun part: actually building the product idea.

How you build your first proof of concept will depend on a number of things. If you have a simple product that you’ve already modeled in a 3D software, you can simply get it 3D printed to create your “proof of concept”.

However, if you have a complex product with a number of mechanical or electronic parts, you’ll have to improvise harder.

Remember that the proof of concept doesn’t have to look good or even resemble the final product. It simply has to work. You can even use common household products to create this early-stage model.

For more complex products, you might have to seek help from a handyman or machinist.

4. Create your first prototype

Your proof of concept shows that your product works. Your 3D model shows what it might look like.

Your next step is to combine the learnings from the proof of concept and 3D model to create your first prototype.

This should be a fairly detailed model that looks like your final product and has the same functions.

It’s not always possible to create this detailed first prototype alone. Depending on the complexity, you might want to get help from a machinist or a specialized prototype designer.

Since this is just the first prototype, you shouldn’t worry too much about the kind of materials used or even the cost. Your objective is to get a working model that resembles your final product.

5. Create a production-ready prototype

The final step before you get to manufacturing is to trim the fat off your first prototype and get it to the production-ready state.

This is essentially a process of cost and feasibility analysis. You have to go through every part of the prototype and figure out ways to cut costs without compromising functionality.

At the same time, you should look at ways to improve the product’s aesthetics or durability.

For example, you might replace an oft-used plastic part with metal, and a little-used metal part with plastic. This will help you cut costs while still retaining quality.

It helps to work with a manufacturer and figure out how different components in the prototype might impact its cost and quality. You should also look at different raw materials and see which ones are more pleasing aesthetically.

Your goal should be to find a balance between cost and quality depending on your target customers. If you’re targeting luxury buyers, for example, quality will be more important than cost. For budget customers, it will be the opposite.

Once you have a production-ready prototype, you can find GPT Precision manufacturer and start selling your idea to the world.