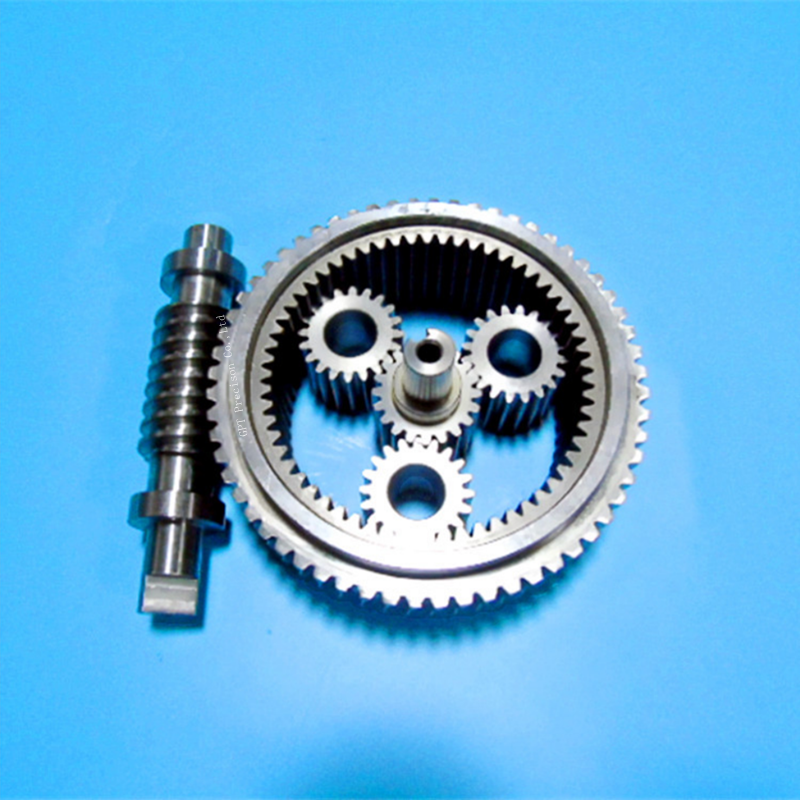

Custom CNC Machining Plastic Small Planetary Gear Set

Customization: Free design(Min. Order: 5000 Pieces)

Shipping: Support Express · Sea freight · Land freight · Air freight

Standard or Nonstandard: Nonstandard

Product name: Custom CNC Machining Plastic Small Planetary Gear Set

Application: Machinery

Module:M1.25 M1.5 M2 M3

Service: OEM Services

Color: Customers' Demands

Package: Customers Specific Requirement

Quality: High-level

Payment Term: T/T L/C Paypal

Sample: Available

- Specifications

In an epicyclic or planetary gear train, several spur gears distributed evenly around the circumference run between a gear with internal teeth and a gear with external teeth on a concentric orbit. The circulation of the spur gear takes place in analogy to the orbiting of the planets in the solar system. This is how planetary gears acquired their name.

The components of a planetary gear train can be divided into four main constituents.

The housing with integrated internal teeth is known as a ring gear. In the majority of cases the housing is fixed. The driving sun pinion is in the center of the ring gear, and is coaxially arranged in relation to the output. The sun pinion is usually attached to a clamping system in order to provide the mechanical connection to the motor shaft. During operation, the planetary gears, which are mounted on a planetary carrier, roll between the sun pinion and the ring gear. The planetary carrier also represents the output shaft of the gearbox.

The sole purpose of the planetary gears is to transfer the required torque. The number of teeth has no effect on the transmission ratio of the gearbox. The number of planets can also vary. As the number of planetary gears increases, the distribution of the load increases and therefore the torque that can be transmitted. Increasing the number of tooth engagements also reduces the rolling power. Since only part of the total output has to be transmitted as rolling power, a planetary gear is extremely efficient. The advantage of a planetary gear compared to a single spur gear lies in this load distribution. It is therefore possible to transmit high torques with high efficiency with a compact design using planetary gears.

Provided that the ring gear has a constant size, different ratios can be realized by varying the number of teeth of the sun gear and the number of teeth of the planetary gears. The smaller the sun gear, the greater the ratio. Technically, a meaningful ratio range for a planetary stage is approx. 3:1 to 10:1, since the planetary gears and the sun gear are extremely small above and below these ratios. Higher ratios can be obtained by connecting several planetary stages in series in the same ring gear. In this case, we speak of multi-stage gearboxes.

With planetary gearboxes the speeds and torques can be overlaid by having a ring gear that is not fixed but is driven in any direction of rotation. It is also possible to fix the drive shaft in order to pick up the torque via the ring gear. Planetary gearboxes have become extremely important in many areas of mechanical engineering.

They have become particularly well established in areas where high output levels and fast speeds must be transmitted with favorable mass inertia ratio adaptation. High transmission ratios can also easily be achieved with planetary gearboxes. Because of their positive properties and compact design, the gearboxes have many potential uses in industrial applications.