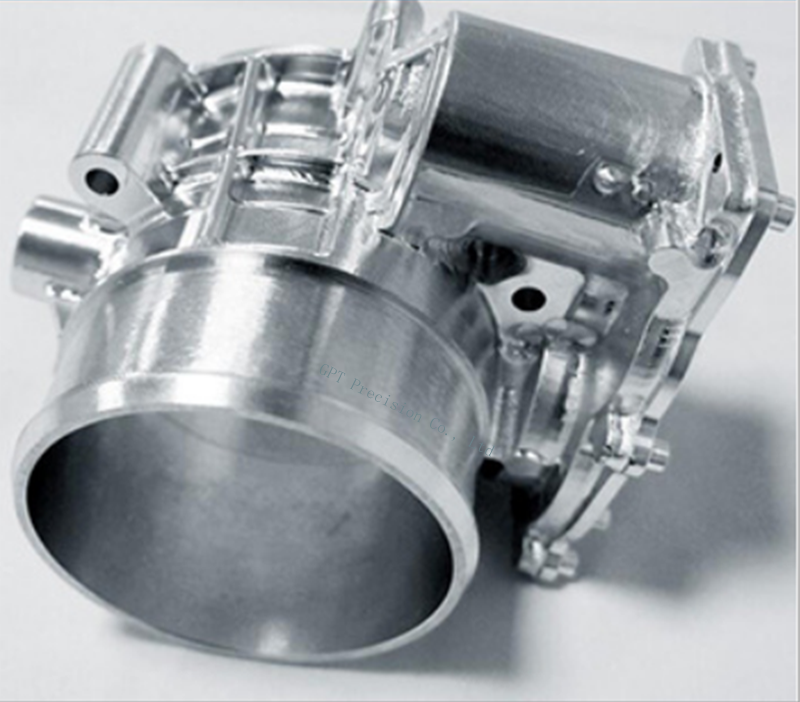

CNC Swiss turning Cold Forging services

Tolerance : 0.01-0.05mm can also be customized

Precision: Average level: ±0.01mm, depending the part size and thickness and material

Quality System: 100% inspection(offer QC report)

Process type: Stamping Surface treatment: Sand blasting, polishing, brush, Anodized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Color: As customer's specific requirements

Standard: GB, EN, API650, China GB Code, JIS Code

Material: Stainless steel,mald steel,zinc alloy,aluminium alloy,brass,bronze,copper,etc.

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

Delivery time: 7-30 days after receive the pre-payments

- Specifications

GPT Precision Co., Ltd is a HARDWARE manufacturing expert in China. We provide the professional CNC turning parts service for you.

Regarding fastener, GPT Precision Co., Ltd satisfies your needs using any of several CNC turning processes including Cold, Warm heading, thread rolling, drilling, Philip head, Pozi head. Available materials have 300 series stainless steel, carbon steel, alloy steel, aluminum and brass.

We know that quality is king. So GPT Precision Co., Ltd has serious QC control system. We follow up ISO9001 which have IQC, IPQC, and FQC to make sure the highest level CNC turning parts to our customers.

GPT Precision CNC Turning Capabilities and Features:

GPT Precision is capable to provide cost-effective CNC Swiss turning services and quality products with high precision and accuracy for vast projects.

Low, medium to high volume batches production run

Rapid prototyping and end-use manufacturing

High dimensional accuracy, high speed and high reliability

A wide range of compatible metal and plastics materials

Great productivity and improved efficiency

Smooth finishes and tight tolerances can be achieved

What is CNC Turning Center – Difference between CNC Lathe and Turning Center

CNC turning center, the equipment or machines for CNC turning service, is a computer controlled 3, 4 or 5-axis machine has capabilities of turning, drilling, tapping, and milling, using live tools with powered rotary tool turret, dual spindles, Y-axis, and multiple turrets. While CNC lathe is a simpler 2-axis machine with one spindle, basically composed of headstock, carriage, tailstock and bed.

When it comes to the CNC turning process, the subtractive manufacturing method is typically performed on CNC lathe or turning center. Before the cutting, G-code and turning machine need to be prepared, then secure the blank bar of stock material in the chuck of spindle, the chuck holds the piece in place when the spindle rotates. With the spindle spins to certain speed, a stationary single-point CNC turning cutter will move on a linear path that parallel to the axis of rotation and remove excess material, reduce the diameter of the block, specify the dimension and create smooth finish, to get final custom CNC turned parts with desired specification.

CNC turning centers have more complex structure than CNC lathes.

CNC turning centers has higher production capabilities and versatility than CNC lathes.

CNC lathes are generally flat-bed type while turning center usually slant-bed type.

There are only minimal protective enclosure around the lathe while turning center commonly equipped with full enclosures to keep chips and coolant splashes within the machine.