CNC turning brass parts

Process type: CNC turning, milling, drilling, grinding, wire EDM cutting etc.

Tolerance : 0.01-0.05mm can also be customized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Color: As customer's specific requirements

Standard: GB, EN, API650, China GB Code, JIS Code

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

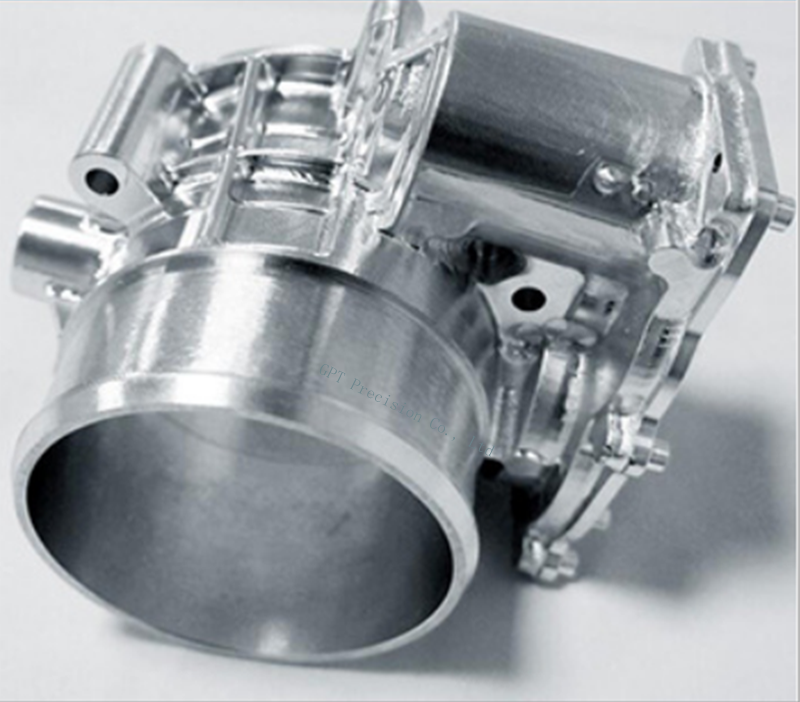

Precision Cnc Machining: 5/4/3 Axis 7075 Aluminum/304 Stainless Steel/brass Parts

Delivery time: 7-30 days after receive the pre-payments

Port: Shenzhen China

- Specifications

Brass machining parts (5 axis and Precision CNC Swiss turning machining) have several key advantages compared to machining other materials. Brass parts and components are durable, cost-efficient, and even create a tighter seal for fittings and have a high heat and corrosion resistancmethodology and application. Brass CNC machining is used in a wide variety of industries, including medical, electrical, plumbing, and even consumer goods. Companies prefer small brass turned parts and components because it's one of the easiest materials to machine. Brass fittings are often used in electronic hardware because of its low stregnth and weight properties and in precision engineering for manufacturing cylinder parts. We use 5 axis machines such as Haas UMC 750 and Haas VF-5SS as well as conventional milling equipment

It can be precision machined easily. Although ductile in its softened state, it is a strong material to work with and maintains its strength even under some of the most demanding conditions. 360 Brass forms a thin protective "patina", which, unlike steel and iron, will not rust when exposed to the atmosphere. As a high-density material is ideal for heavy industrial parts

In CNC turning parts services, brass is one of the most used materials because of its excellent ductility, thermal conductivity, durability, mechanical and highly resistant to corrosion properties. Brass is a malleable alloy mainly composed of copper and zinc, easy to machine, mold, stamp. In addition, according to the use for which it is intended, the brass may also contain lead, tin, nickel, chromium or magnesium. It is generally called tombac, Florentine (or Venetian) bronze, similor, archal or pinchbeck. Due to its varied properties, brass has been the most widely used copper alloy in the world, and CNC Turning is the best cost effective way to process the brass for manufacturing CNC Brass precision Turning Parts and end-use bronze products, which are widely used in watch making, decoration, metalwork, advanced industry, the manufacture of musical instruments or in our bathrooms (faucet, shower hose, lock, etc.) .

Properties of Brass, Copper, Bronze

Resistance to salt water

Easy to machine, cut and die-cast

Corrosion resistance

Forming capacity by casting, forging, cutting and machining

Lamination possible

The malleability varies according to the composition and temperature

Recyclable