China CNC Turning and Milling Services

Tolerance : 0.01-0.05mm can also be customized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Color: As customer's specific requirements

Standard: GB, EN, API650, China GB Code, JIS Code

Material: Stainless steel,mald steel,zinc alloy,aluminium alloy,brass,bronze,copper,etc.

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

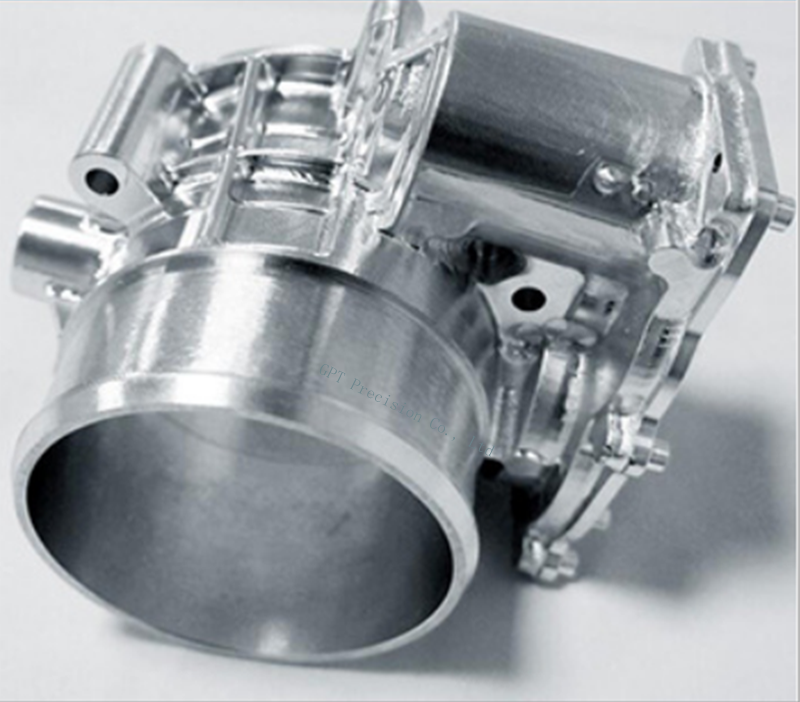

Precision Cnc Machining: 5/4/3 Axis 7075 Aluminum/304 Stainless Steel/brass Parts

Surface treatment: Zinc plating,chrome palting,nickel plating,painting,sand blasting,powder coating,polishing,anodized,baking finish,oxidation,electroplate,passivate

- Specifications

CNC Turning and Milling Services – Top China CNC Mill-CNC turning parts & Products Manufacturer

GPT Precision is a leading CNC manufacturing company in China, providing efficient and quick CNC milling and turning services for precision machined components manufacturing and prototyping. We have sophisticated high-performance multi-axis CNC milling-turning center, accomplished workers and operators to provide quality custom CNC turn-mill parts with improved productivity and outstanding flexibility. Our CNC design and engineering team will review your drawings carefully and rigorously, then give you proper advice or start the machining cycle. You can get detailed CNC mill-turning quote fast as long as you sent your metal or plastic parts design drawings. Highly automated CNC programming will speed up and simplify the machining of CNC milling and turning components and achieve tight tolerance, smooth surface and complex geometries to meet your requirements.

What is CNC Milling and Turning Service (CNC Turn-Milling Compound)

CNC turning or CNC milling allows to manufacture CNC parts in single handling, while CNC milling-turning is a compound machining technology, to execute designed multiple kinds of tasks with the computer numerical control when the cutting tool and workpiece are both rotating. With CNC milling and turning services, complex curved or special-shaped parts can be produced through the processing of multiple surfaces on the CNC milling-turning center. CNC turn-milling machine can reach any surface of the components. Most of the CNC turn-milling compound process can be completed on the CNC turning center. There are two different CNC turning-milling types:

– Contour machining when the workpiece is parallel to the cutter axis

– Surface machining when the workpiece is vertical to the cutter axis.

Features of CNC Milling and Turning

– Shorten manufacturing process chain and higher efficiency

– Reduced clamping times and improved machining accuracy

– Free-moving worktable and high precision built-in spindle

– Mainly for mass production of small parts or complex components in high speed and diversified processing.

– Designed parts can be produced in one-time processing

– Suitable for cutting copper, iron, aluminum, stainless steel(China CNC turning Stainless Steel parts), brass(China CNC Brass Turning parts), plastics and more materials.

– More precise products, faster speed and decreased cost than single machining

Metals:

Aluminum, alloy, titanium, stainless steel, steel, copper, bronze, brass, etc.

Plastics:

POM, ABS, PEEK, PMMA, HDPE, Nylon, PLA, PC, PP, PTFE, etc.

Other Materials: Graphite, VeroClear