China CNC Brass Turning Services

Port: Shenzhen China

Production Capacity: 20000

Tolerance : 0.01-0.05mm can also be customized

Payment Terms: L/C, T/T, Western Union

Shaping Mode: CNC professional turning

Surface treatment: Polishing, Anodizing, Painting, Silk Print, etc

Material: Stainless steel, mald steel ,zinc alloy ,aluminium alloy,brass ,bronze ,copper ,etc.

Application:Car, Household Appliances, Furniture, Commodity, Electronic, Home Use, Hardware

- Specifications

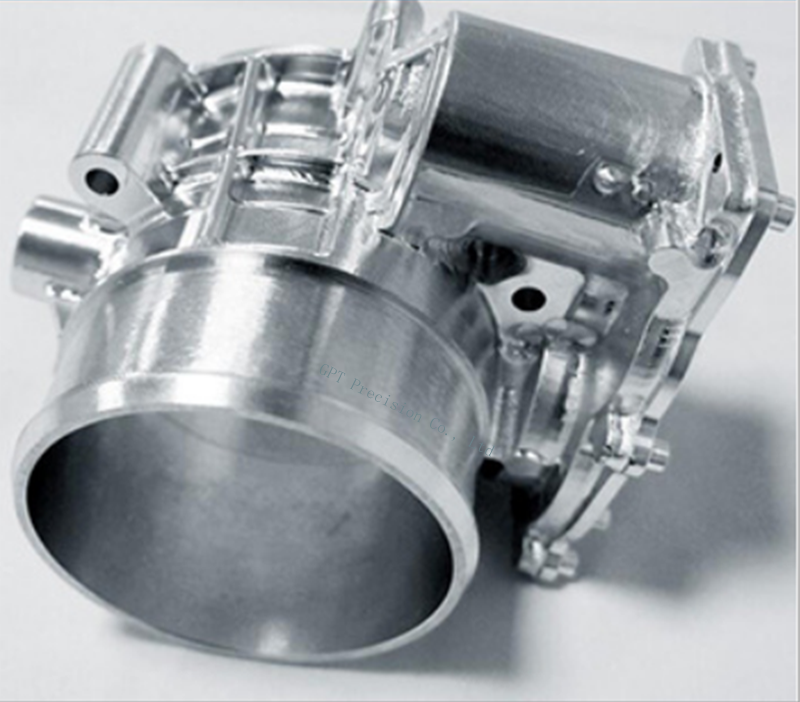

China Top-Grade Precision Brass CNC Turning Supplier

Are you looking for the most profitable but excellent quality CNC Brass (Copper, Bronze) Turning services for your project? GPT Precision Co., Ltd as one of the China Leading brass CNC machining services suppliers and CNC brass turning parts manufacturers, has complete confident to be your best business partner. Now you can easily order your bronze turned products and receive them anywhere in the world by express parcel. Our CNC Copper turning processing technology selects a variety of excellent materials, integrating industry-standard brass single prototypes and complex bronze component products. Get the most cost-effective high quality custom brass CNC turning service (CNC Copper Turning, CNC Bronze Turning) from GPT Precision, send us your drawing to us now, in less than 24 hours, you will receive a quote online and inform you of your expected delivery time.

In CNC turning parts services, brass is one of the most used materials because of its excellent ductility, thermal conductivity, durability, mechanical and highly resistant to corrosion properties. Brass is a malleable alloy mainly composed of copper and zinc, easy to machine, mold, stamp. In addition, according to the use for which it is intended, the brass may also contain lead, tin, nickel, chromium or magnesium. It is generally called tombac, Florentine (or Venetian) bronze, similor, archal or pinchbeck. Due to its varied properties, brass has been the most widely used copper alloy in the world, and CNC Turning is the best cost effective way to process the brass for manufacturing CNC Brass Turning Parts and end-use bronze products, which are widely used in watch making, decoration, metalwork, advanced industry, the manufacturing of musical instruments or in our bathrooms (faucet, shower hose, lock, etc.) .

Various Quality Copper Materials: Brass 360, Brass 308, Copper 101, Copper 110, Copper 11000, Bronze

Multiple Surface Finishes: Electroplating, Galvanizing, Gilding, Glazing, Knurling, Painting, Passivation, Anodizing, Peening, Powder coating, Vacuum plating, Abrasive blasting etc

Quality Guarantee: Advanced CNC turning machines, capable designers and engineers, and experienced production workers ensure excellent quality

Custom OEM Capacity: Provide customers with the best design and production solutions according to the drawings and parameters

Competitive Prices: Offer the advanced CNC Brass Turning technology currently available to large companies at the profitable prices accessible to any user.

Properties of Brass, Copper, Bronze

Resistance to salt water

Easy to machine, cut and die-cast

Corrosion resistance

Forming capacity by casting, forging, cutting and machining

Lamination possible

The malleability varies according to the composition and temperature

Recyclable