Blog

Read informational articles, guides & tips, Learn about the manufacturing world in China

What is CNC Bending?

Computer numerically controlled (CNC) bending is a manufacturing process that is carried out by CNC press brakes (also known as CNC brake presses). These machines can bend sheet metal work from just a few mm across to sections many metres long on the largest industrial machines. CNC press brakes either have a fixed bottom bed with the V block tooling …

What Is CNC?

CNC stands for Computer Numerical Control is an automated control of machining tools such as; drills, lathes, mills, and 3D printers using a computer. It takes digitized data and is controlled, automated and monitored by a computer and CAM (Computer-Aided Manufacturing) program. CNC machines are fully automated, needing only digital files with instructions about cutting trajectories and tooling. It is …

When to avoid CNC machining

When to avoid CNC machining Our advice on when to choose CNC machining should give you a fairly good idea of when to avoid CNC machining. The limitations of the process making it less desirable in situations when complex geometries are required, or when extreme order quantities are needed. The turnaround can also be a factor: if a part is …

When Should You Choose CNC Machining?

When Should You Choose CNC Machining? CNC machining is a hugely versatile and reliable manufacturing process used for a variety of applications. Whether for prototyping or production, metals or plastics, CNC machining is an essential tool for engineers in manufacturing, automotive, aerospace, medicine, consumer products, and many other industries. But that doesn’t make CNC an automatic choice for all projects. …

WHAT IS PRECISION MACHINING USED FOR?

Precision machining is a subtractive process used in cases where material needs to be removed from a raw product to create the finished product. Precision machining can be used to create a wide variety of products, items, and parts for any number of different objects and materials. These parts usually require tight tolerances variation from nominal dimensions and from part …

WHAT IS PRECISION MACHINING

WHAT IS PRECISION MACHINING? Precision machining is a type of technical manufacturing that is essential in creating and designing machines, parts, tools, and other hardware that are essential in modern manufacturing to maintain process controls and tolerances that function under extremely tight specifications. It is used to make up the many large and small objects and their components that we …

What are the benefits of CNC bending technology?

CNC bending is an economical method of producing 3D parts from metal sheets. Bent sheet metal parts are commonly made using a pneumatic or hydraulic press brake, where a metal sheet is pressed between a punch and die to bend it to the desired angle or shape. Prior to the introduction of CNC bending technology, producing sheet metal components with …

What is Shearing

Shearing is a scissor-like process used to rough-cut materials in preparation for other manufacturing processes. In a machine shop setting, shearing is commonly done by a hydraulic squaring shear, sometimes referred to as a guillotine shear. Depending on the tooling used, shearing can be used to make straight cuts in materials including sheets, bars, and angle stock. The shearing process …

What is Countersinking

A countersink is a conical hole cut into a manufactured object, or the cutter used to cut such a hole. A common use is to allow the head of a countersunk bolt, screw or rivet, when placed in the hole, to sit flush with or below the surface of the surrounding material (by comparison, a counterbore makes a flat-bottomed hole …

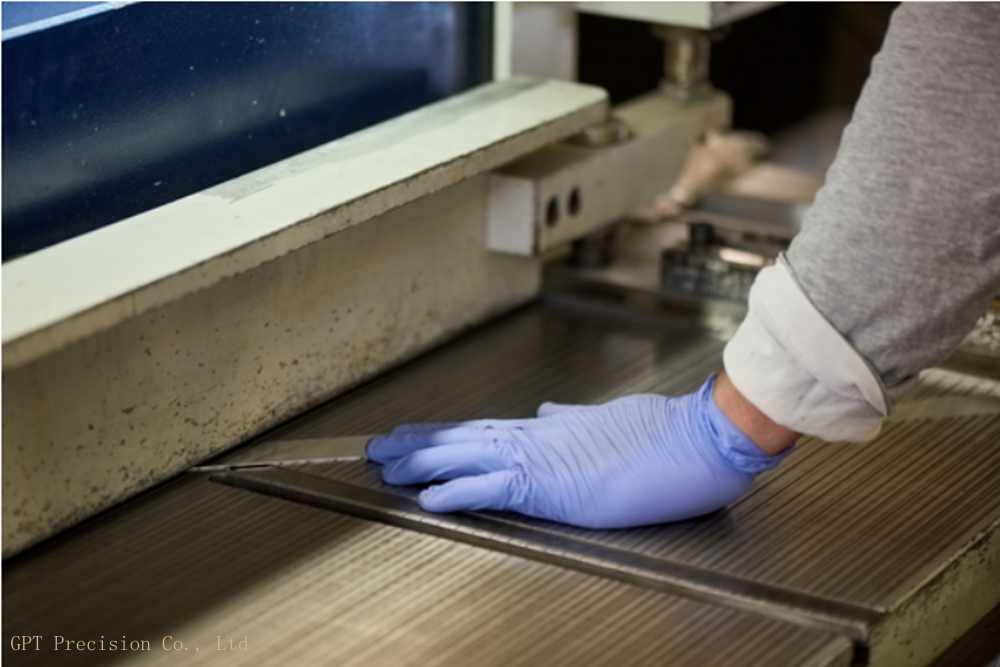

What is Surface Grinding

Surface grinding is a process that creates a precise, smooth flat-surface by moving a workpiece back and forth under an abrasive grinding wheel. Surface grinders produce flat parts with high tolerances and low surface roughnesses. They are commonly used when making machine tools, reference surfaces, jig plates, and optical platforms. Surface Grinder Surface grinding is an abrasive process. It involves …

What is the purpose of Knurling

Knurling is a process that creates a rough-textured pattern on ductile metals, usually for the purpose of enhancing grip and appearance. Common applications include handles, knobs, and thumbscrews. Knurling is made by pressing a hardened tool with the reverse of the pattern against a part being rotated by a lathe. Common patterns include straight, angled and diamond knurls. In manufacturing, …

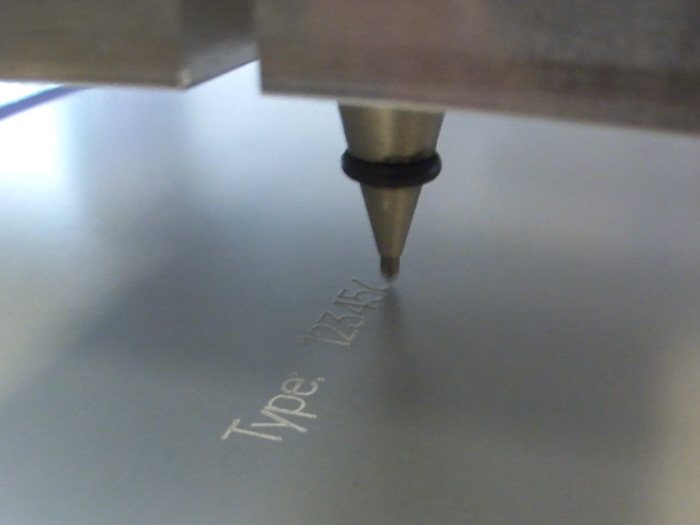

What is CNC Engraving?

Engraving is the art of carving a design into a hard surface.CNC engraving is a computer-controlled method of cutting designs into metal and plastic surfaces. Applications of engraving include logos, text, serial numbers, QR codes and more. Types of Engraving Dot peen engraving, also known as “pin marking,” is performed utilizing a probe that rapidly indents dot-shaped marks into a …