Blog

Read informational articles, guides & tips, Learn about the manufacturing world in China

CNC Machining Vs Die Casting – Which Is Better?

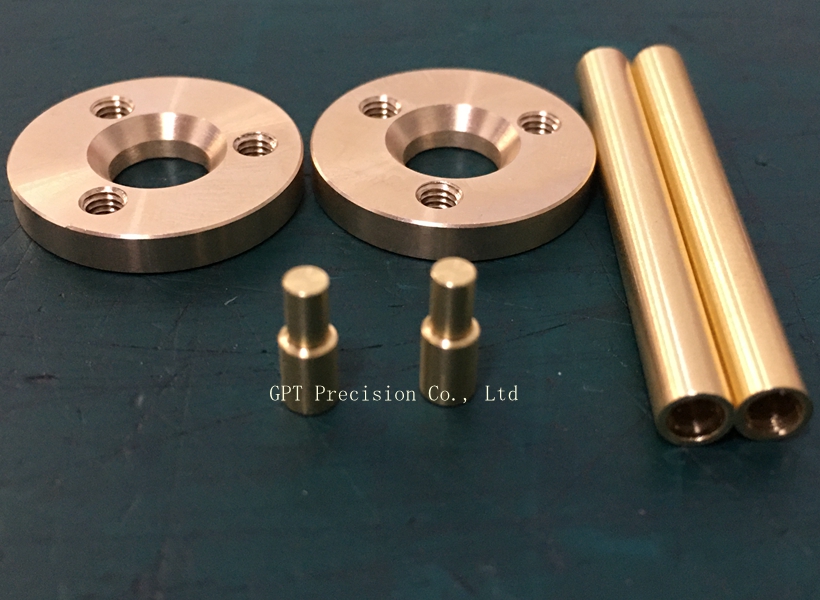

Two of the most popular industrial processes for creating metal parts are die casting and CNC machining. Both processes can even be combined for the best possible finish. However, when it comes to choosing one process over the other, there are several important factors to consider. Two of the most popular industrial processes for creating metal parts are die casting …

What are the Benefits of CNC Turning?

CNC machining is far better than manual machining for a few specific reasons: Accuracy: Programming a CNC to complete a job creates a consistent and accurate cut to ensure product quality. It can be repeated over and over in the exact same manner. Cost Effectiveness: The cost of hiring a person to manually machine parts at scale is far more …

What is a lathe?

A lathe is a machine tool that is used to remove metal from a workpiece to give a desired shape and size. A lathe machine is typically used for shaping the material into the desired form by removing the excess material from a given workpiece. Lathes are commonly used in metal working and metal spinning. A lathe is one of …

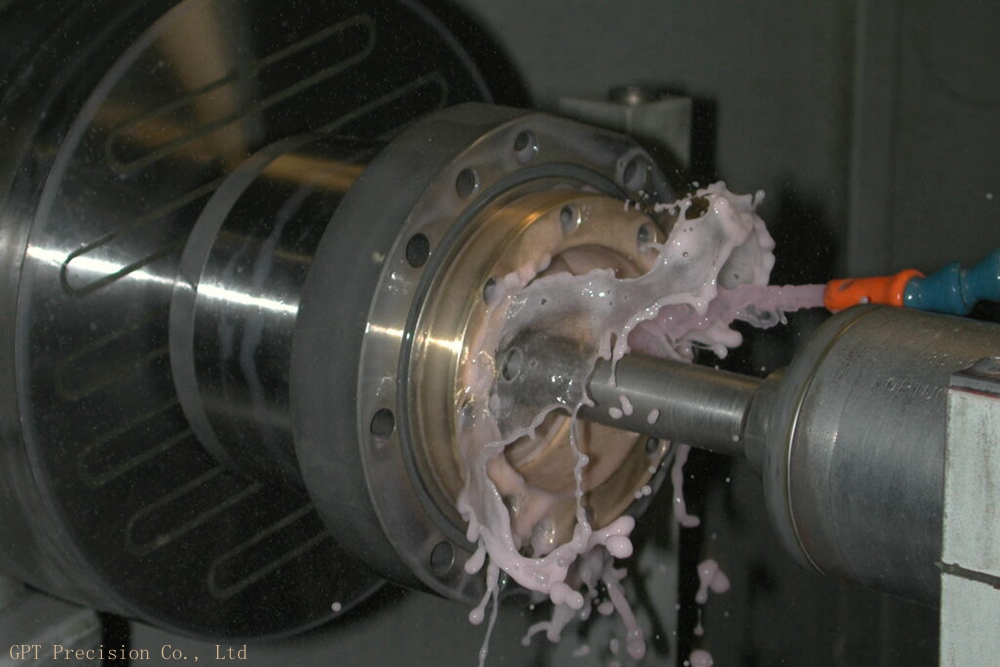

What is CNC Turning?

CNC Turning is a manufacturing process in which bars of material are held in a chuck and rotated while a tool is fed to the piece to remove material to create the desired shape. A turret (shown center), with tooling attached is programmed to move to the bar of raw material and remove material to create the programmed result. This …

What Are the Common Types of Lathes?

The most common machine tool is a lathe, which can be divided into different types according to different processing conditions for the turning process. The lathe machine is used to remove excess material from the workpiece so that the workpiece conforms to the desired style and size. Depending on the characteristics, the following types can be divided into several types: …

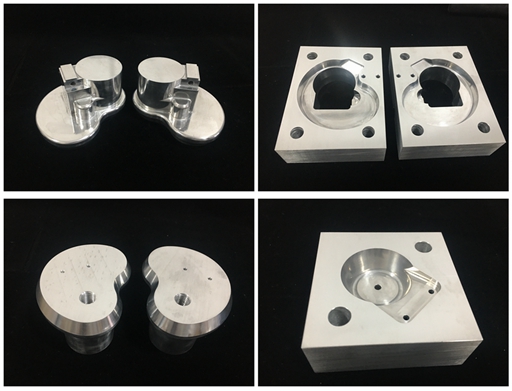

What Are the Basics of CNC Milling and Turning?

Computer Numerical Control (CNC) technology has dominated the metal forming industry in recent years, as it offers advanced precision and repeatability that can be impossible to achieve with manual processes alone. With so many CNC technologies on the market, it can be difficult to distinguish between them and what they are used for. While there are many similarities between CNC …

the many tools available for CNC milling

What Are Chamfer Mills? Chamfer mills do not have blades along the edges, only at the tip. These are used to cut angled edges. The cutting blades on each chamfer mill are called “flutes.” The more flutes on the mill, the more delicate the cut. But fewer flutes on the mill remove more material each turn, for faster production. Balancing …

How can you improve the machinability of Aluminium

The machine-friendliness of aluminum has made it the number one metal for machining. Its material properties make it easy to mill, drill, cut and punch, while aluminum machined parts can be strong, durable and aesthetically pleasing. All in all, aluminum is the most machinable metal on the market. Despite this, aluminum is far from perfect. Its easy machinability is counteracted …

How To Carry Out Precision CNC Machining?

Precision CNC machining is a general term used for a variety of machining applications. “CNC” stands for Computer Numerical Controlled and refers to the programmable feature of the machine, allowing the machine to perform many functions with minimal human control. Precision CNC machining is the fabrication of a component using a CNC controlled machine. The term describes a range of …

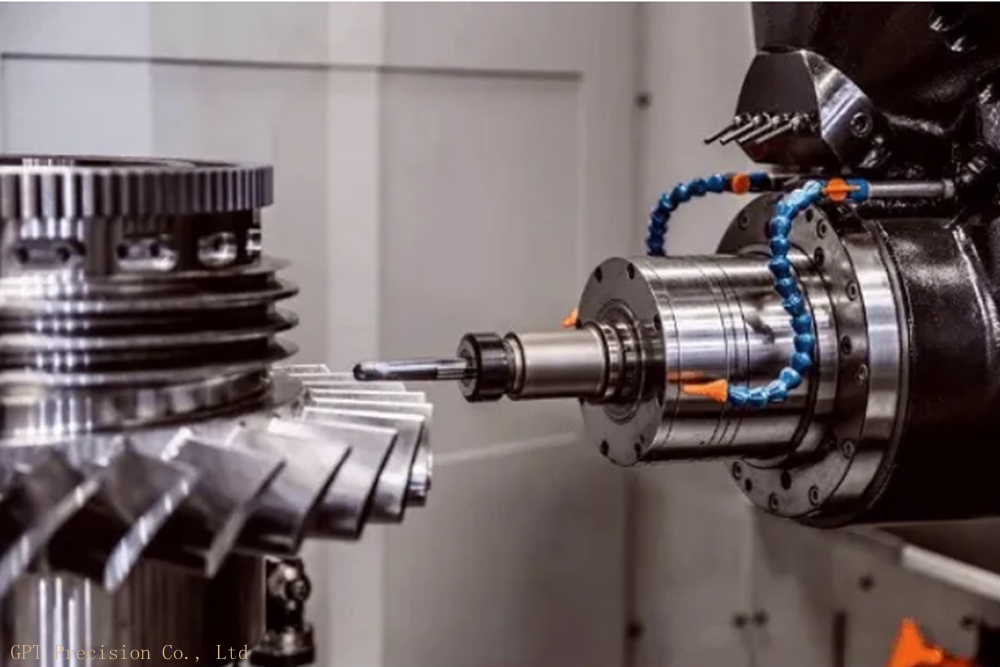

WHAT’S THE DIFFERENCE BETWEEN 3-AXIS, 4-AXIS & 5-AXIS MILLING?

At GPT Precision, we have a range of state of the art 3-axis, 4-axis and 5-axis milling machines. As a designer, having an understanding of which type of machine your part will be manufactured on is critical in optimising your design. When designing a CNC machined part, you might not have thought about which type of machine your part will …

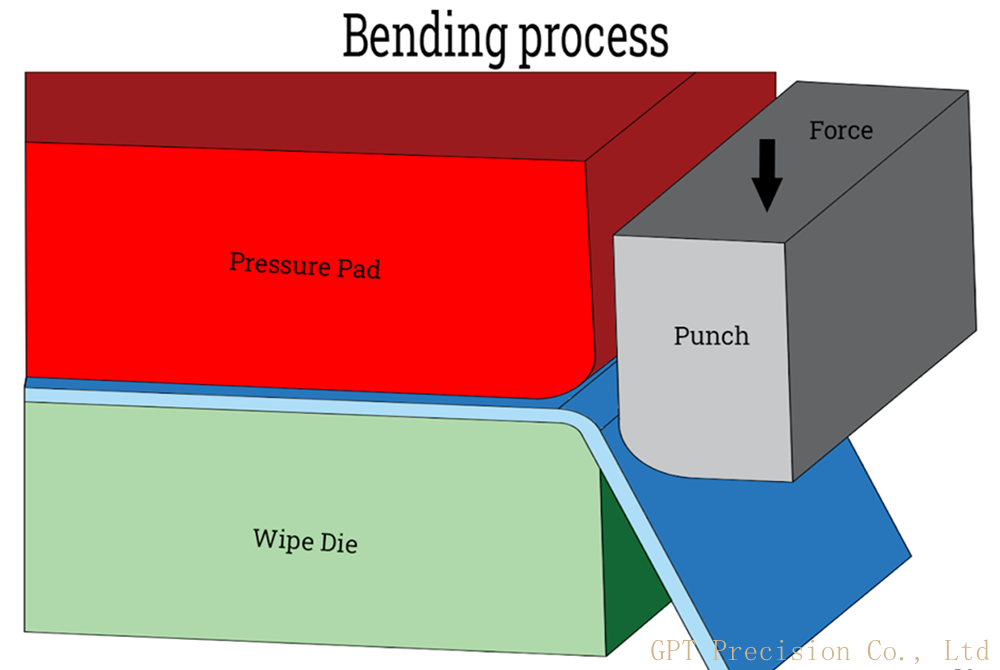

How Does Sheet Metal Fabrication Work?

illustration of sheet metal process During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry, a sheet metal punch (2) can form additional features. Once the parts are deburred, they move to the press brake (3) where they are formed …

HOW TO CHOOSE THE PERFECT CNC MACHINE FOR YOUR PRODUCTION

Machine centers are known for their high precision, high reliability, high efficiency, and the ability to machining complex workpieces. However, if the selection is not thought of thoroughly, you will not be able to exert its due benefits, and with the high cost of the machining centers now a days, you really want to guaranty your ROI (return of investment). …