Surface Finishes Basics

February 16, 2023

Surface Finishes Basics

Metal surface finishing is essential in part production. No matter how good the finished part is, quality metal surface finishing can only make it better.

Surface finishing is also referred to as surface texture, surface roughness, or surface topology. It is the process of altering a metal’s surface by adding, removing, or reshaping. Machinists use metal surface finishing for protective chemical reactions on metal surfaces and to also beautify them.

Choosing the type of metal surface finish to use on metal is just as important as the process itself. The type of surface finishing used is dependent on the end users of the product. For instance, medical-grade and optical instruments require the finest surface finishing. However, other less sensitive industries or application areas may not require such fine finishing.

What Is a Surface Finish?

Surface finish is a term that refers to the process used to alter a metal’s surface by adding, removing, or reshaping. The goal is to protect the metal and improve the aesthetic side.

The result depends on the metal finishing method. Often, there are a few different ways to achieve the same or similar results.

For example, metal finishing that involves a coat of paint can be done through anodizing, powder coating, or wet painting. The results are similar but not the same.

The Importance of a Surface Finish

A proper surface finish ensures that the final product looks better and lasts longer. So the biggest beneficiary is the end-user. At the same time, some surface finishing techniques also help the manufacturers in the production process.

For example, brushing the surface before applying paint increases the metal’s adhesion. This makes a good-quality finish easier to obtain.

Among the many benefits obtained from surface finish processes, we can highlight the following:

Increased corrosion resistance

Helping with the adhesion of paint and other coatings

Elimination of surface defects

Increased resistance to chemicals

Improved conductivity and added surface electrical conduction

Increased strength and resistance to wear while the friction effects are minimized

Enhanced aesthetics

Clearly, surface finishing brings along some great qualities. And this list is not comprehensive, it only includes the most common reasons for applying a surface finish.

What Is the Unit of a Surface Finish?

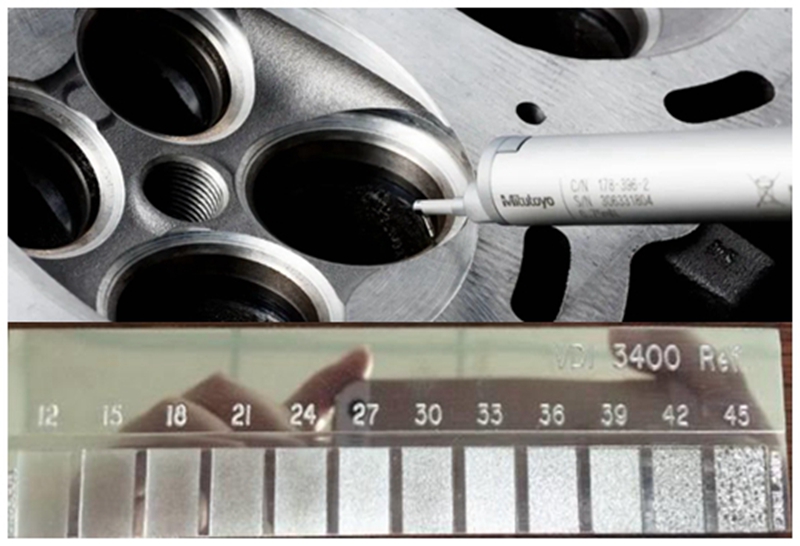

One way to compare surface finishes is by looking at the surface roughness. Roughness represents the smoothness of the surface. But a smoother surface is not always advantageous. Rather, it depends on the use case.

There are several parameters for showing surface roughness. The most common is Ra. This shows the arithmetical mean deviation on the surface.

In essence, a smaller number means a smoother surface. Usually, surface roughness is shown in micrometers. There is also a standardized table for ISO grades that each account for a certain roughness value.

What is meant by Surface Finishing?

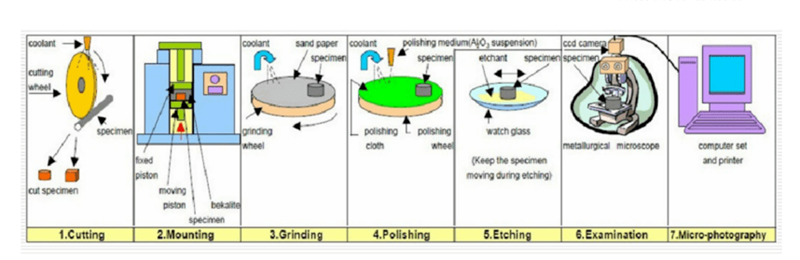

Surface finishing refers to a wide range of industrial processes to obtain certain required properties on the surfaces of manufactured products. Surface finishing is performed by mechanical, chemical, or electrical means and they work by removing, altering, adding, or reshaping the material. The final looks and durability of a product are decided by the surface finish of that part. Surface finishing is applicable to all useful materials like metals, plastics, ceramics, concretes, or any other engineering materials. Surface finish is also known as surface texture or surface topography which represents the characteristics of the surface.