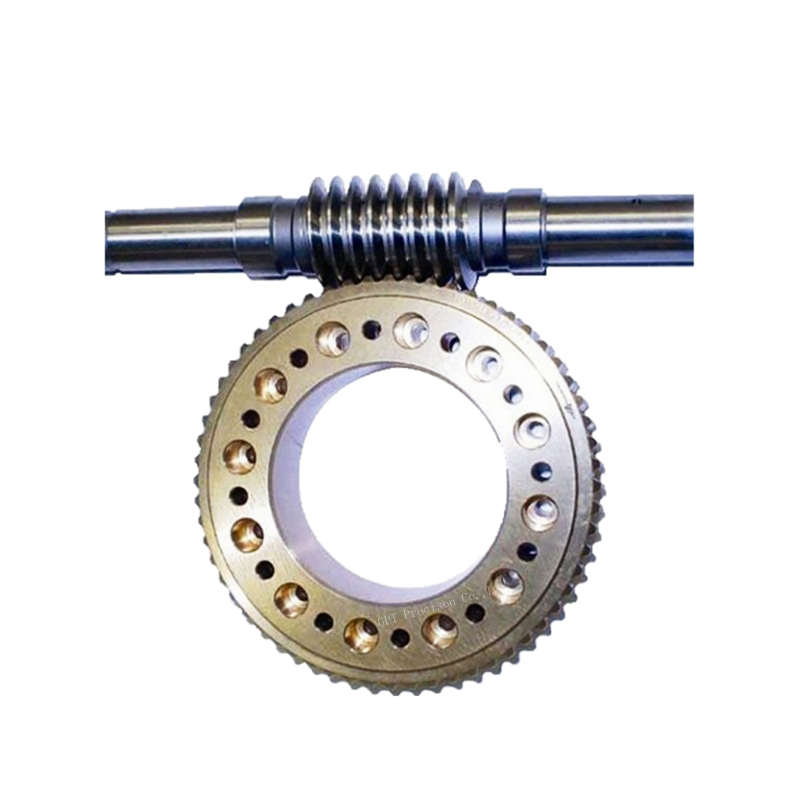

Top Quality brass mini worm gear

Lead Time: Quantity(Pieces) 1 - 100 >100 Est. Time(days) 7 To be negotiated

Customization: Customized logo(Min. Order: 10 Pieces)

Customized packaging(Min. Order: 10 Pieces)

Shipping: Support Sea freight

Application: Machinery

Length: Customized length

Module:M1.25 M1.5 M2 M3

Service: OEM Services

Color: Customers' Demands

Package: Customers Specific Requirement

Support: 1.5 years for machinery warranty|1.5 years for Core Components

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops.

- Specifications

Worm Gear Lubrication

The amount of stress, torque, and motion worm gears deal with requires the use of lubricants to provide good lubricity in metal to metal contact. Mineral based lubricants are commonly used with worm gears; they are made from mineral oil, a product of crude oil. The goal of a worm gear lubricant is to protect the worm drive from friction, corrosion, and inefficiency.

It is impossible for a lubricant to prevent gear wear indefinitely. A combination of natural and synthetic additives provide extra protection and increase the worm gear’s longevity.

The viscosity of a lubricant prevents the worm from touching the wheel in the worm gear assembly. The load and size of the gearing determines the type of lubricant.

There are difficulties associated with lubricating worm gears due to their design. Much of the problem is caused by the sliding motion of the gears as it wipes away the lubricant.

The sliding motion of worm gears is the reason for the use of metals with a low friction coefficient; the worm wheel is a yellow metal such as bronze or brass and the worm gear is a hardened metal such as steel.