How Does Sheet Metal Fabrication Work?

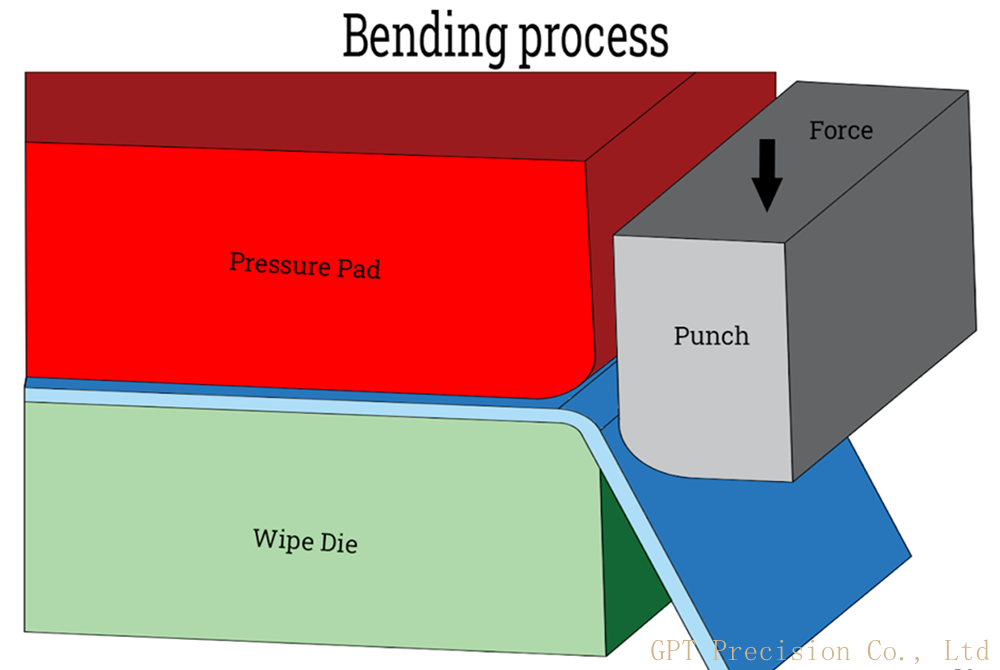

illustration of sheet metal process During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry, a sheet metal punch (2) can form additional features. Once the parts are deburred, they move to the press brake (3) where they are formed …

Sheet Metal Fabrication Finishes

Finishing is a most important step in fabrication. Finishing is the final step in preparing Sheet Metal fabrication products for use. Finishing makes products more resistant to corrosion, adds an extra layer of durability and makes surfaces look their best. Finishing provides higher electrical, chemical or tarnish resistance. A product’s finish is determined by its use. Here are some factors …

metal stamping

Choose the right material for your Stamping Parts. GPT Precision Co., Ltd supplies metal stamped parts ranging from small precision parts to large precision metal stamped components that are used for medical,lighting,automotive,marine and construction filed.We have the capability to work in quantities from prototype runs to full production runs. Our thickness for metals ranges from 0.2mm to 6.5mm.If you have …