How Does Sheet Metal Fabrication Work?

illustration of sheet metal process During the sheet metal fabrication process, thin sheet metal stock is placed on a flat bed where a laser cutter (1) draws programmed part patterns. Depending on the part geometry, a sheet metal punch (2) can form additional features. Once the parts are deburred, they move to the press brake (3) where they are formed …

Metal Finish processes Services

Because finishing processes affect surface finish (and therefore part size), we do not recommend applying secondary finishes to high-tolerance parts, as the finishing process can remove or add enough material to put the finished part out of size tolerance. GPT Precision Co., Ltd offers the following secondary finishes for your machined and Sheet Metal fabrication parts. Chem-Film Coating: Also known …

Sheet Metal Fabrication Services

GPT Precision Co., Ltd have fully-equipped sheet metal shop with welding, shearing, punching facilities. We also carry a large inventory of stainless steel(1-12mm), aluminum(1-10mm), and galvanized sheet (1-20mm) stock in order to continuously provide immediate service. Our custom precision Sheet Metal fabrication services offer a cost-effective and on-demand solution for your manufacturing needs. What is Sheet Metal fabrication? Sheet Metal …

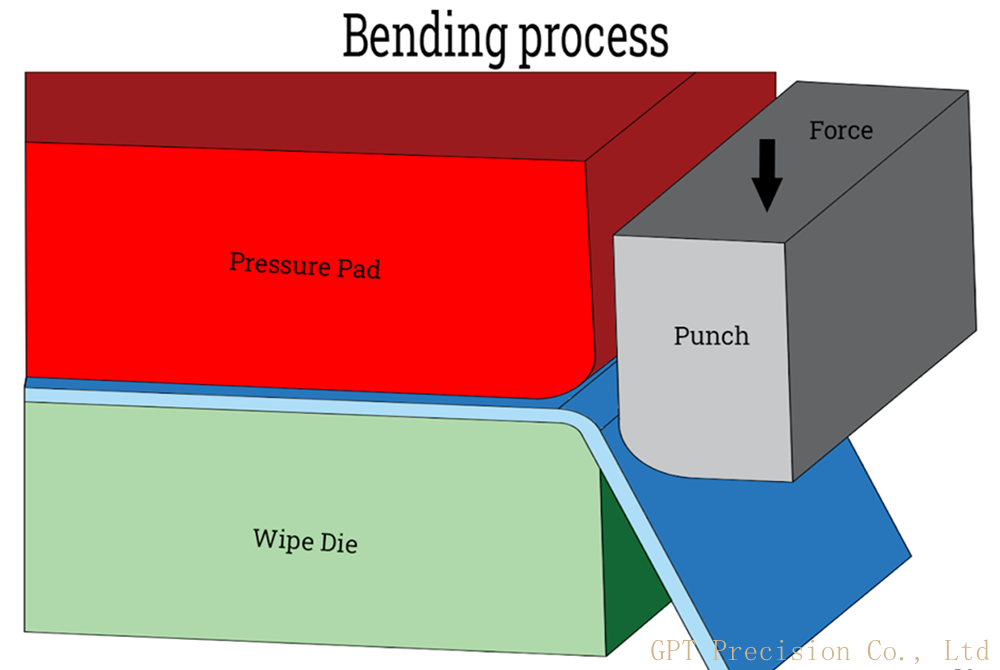

Custom sheet metal stamping

Advanced sheet metal stamping services include numerous types of sheet metal forming manufacturing processes including punching, stamping, blanking, embossing, bending, flanging, and coining. Metal stamping service processes generally involve single stage or multi-stage operations, where the die/tool utilizes a single stroke or multiple strokes to produce the desired form or part from the strip or sheet metal. GPT Sheet Metal …