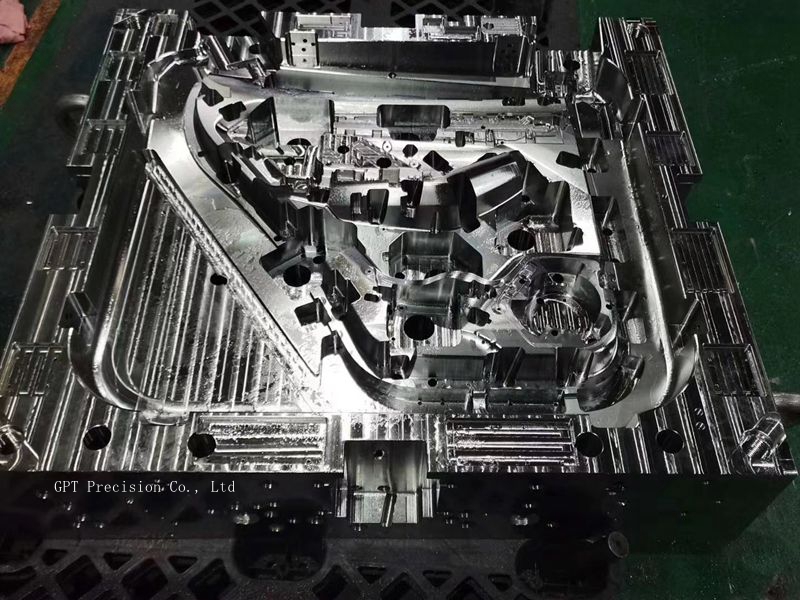

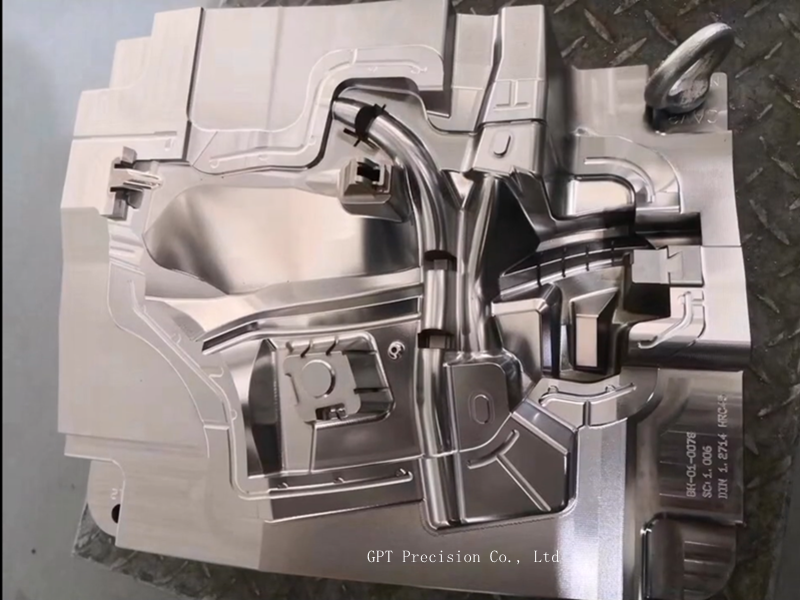

precision automobile mould

Get Latest Price

Min. Order / Reference FOB Price

Port: Shenzhen, China

Production Capacity:100

Payment Terms: L/C, T/T, D/P, Paypal, Western Union

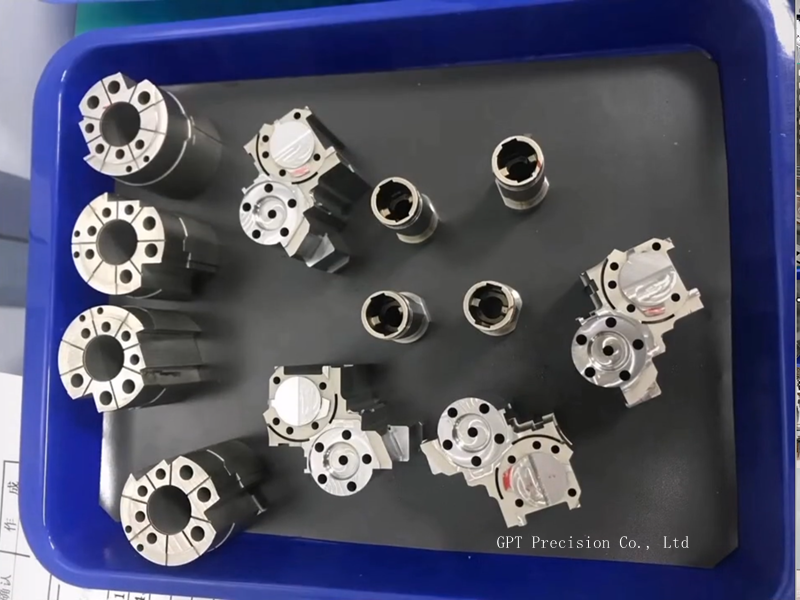

Surface Treatments: Polishing, Texturing, Sandy finish, etc.

Material: steel

CNC Machining or Not:CNC Machining

Transport Package: Wooden Box

Specification: depend on inquiry

Trademark: GPT Precision

Origin: Shenzhen China

- Specifications

GPT MOLD Specializes in Ultra-Precision Injection Molding of Plastic Parts

GPT MOLD, Inc specializes in high precision injection molding of plastic parts. The cornerstone of achieving high precision is the minimization of process variation during injection molding. Process variation can be caused by any external variable that causes change in the resulting plastic part’s dimensions or physical properties. Examples of such external variables include the plastic material’s consistency, the molding machine’s accuracy, and the thermodynamic control of the injection mold.

Advanced State of the Art Facility

Injection Molding Capabilities GPT MOLD has some of the most advanced injection molding capabilities and can take care of all your molding needs from various size capabilities of components, ultra-precision tolerances, our variety of materials, run size limits, and convenient location.

Innovating Manufacturing Technology

For many years, injection molding has been a trusted manufacturing technique for creating all kinds of plastic products and components. Injection molding meets the needs of many industries, but with new technologies, the injection mold part services industry is changing dramatically across countless different vertical markets. Key trends such as mold re-shoring, 3D printing, increased product customization, and new injection materials are sweeping the industry as companies push for lower product and manufacturing costs. Injection molding is sufficient for mass producing a wide range of parts and components, but for highly functional parts, a newer technology is needed—precision injection molding (PIM).

Precision injection molding is used to create specialized parts in industries like electronics, automotive, medical devices, optics, and more. Parts produced through precision injection molding can be used in advanced technical devices, products where small form factors are essential, or as replacements for precision metal sheet stamping parts. As an expert in manufacturing solutions with access to a global network of suppliers and leading-edge technology, GPT MOLD offers customers many ways to maximize product offerings, including the use of precision injection molding etc.

Benefits of Precision Injection Molding

With the innovations in injection mold technology, businesses look to using precision injection molding for more technical applications while enjoying its benefits for a high-volume production process that is also cost effective:

Efficient production – injection molding is faster than other molding techniques, allowing for more parts to be made from a single mold

Strength – the use of fillers and other material blends can give plastics strength while reducing cost

Complex designs – parts with high levels of detail or complex geometries can be made at high volumes

Reduced cost – the use of automation techniques using CNC machine solutions helps reduce labor cost while increasing production efficiency

Customers with complex, high volume part requirements need trusted partners with comprehensive capabilities and effective collaboration. GPT mold combines design for manufacturability expertise, from concept to high-volume manufacturing, that has served global customers for over 15 years.