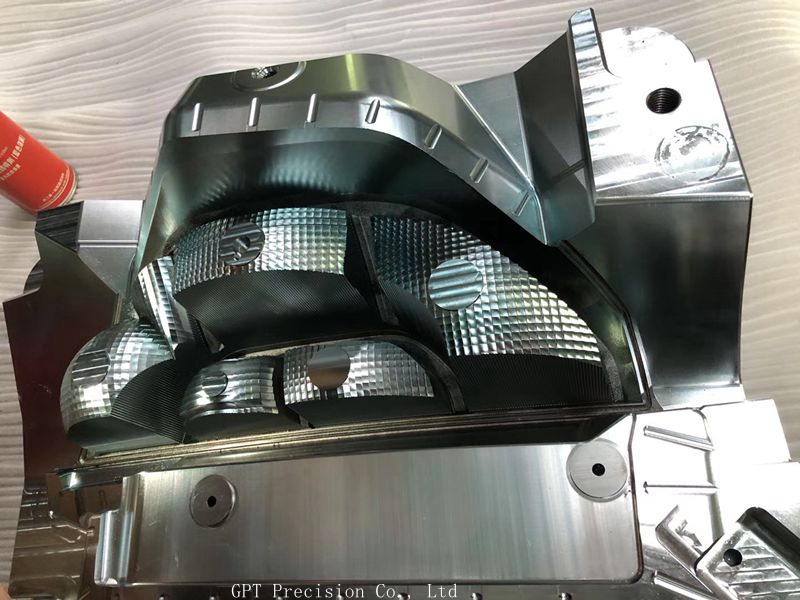

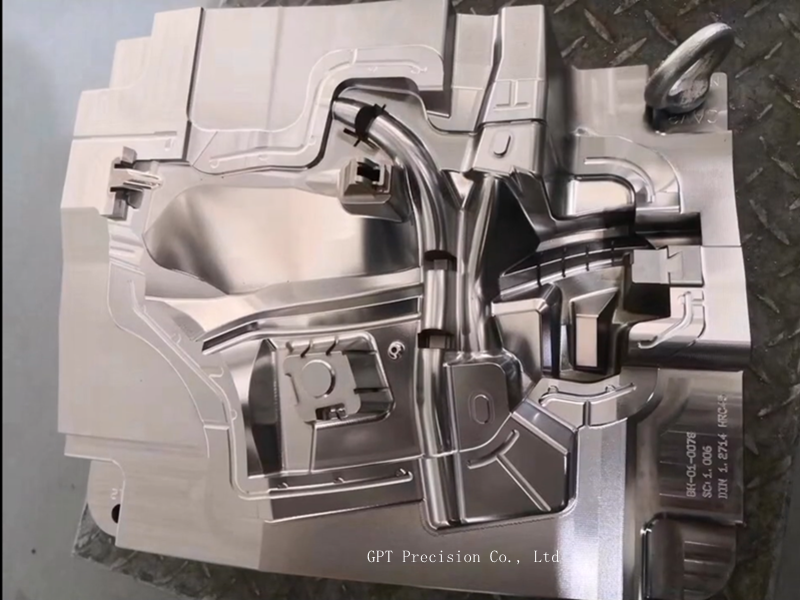

plastic Optics&len mould

plastic Optics len mould

Get Latest Price

Min. Order / Reference FOB Price

Port: Shenzhen, China

Production Capacity:100

Payment Terms: L/C, T/T, D/P, Paypal, Western Union

Surface Treatments: Polishing, Texturing etc.

Application: LED Lighting,Microlenses,Polymer lenses,Life Sciences and medical technology,Automotive.

Material: steel

CNC Machining or Not: CNC Machining

Transport Package: Wooden Box

Specification: depend on inquiry

Trademark: GPT Precision

Origin: Shenzhen China

- Specifications

GPT mold is one of the few manufacturers capable of producing high-precision plastic lenses using injection molding processes. The customer-specific products developed in our facilities, ranging from lighting design to finished lenses, meet the necessary requirements and are highly precise: We combine our interdisciplinary competences in lens and component design, high-tech tool and mold making, process development for plastic replication,.We thus fulfill both quality and economic requirements with highly developed processes and a wealth of experience.

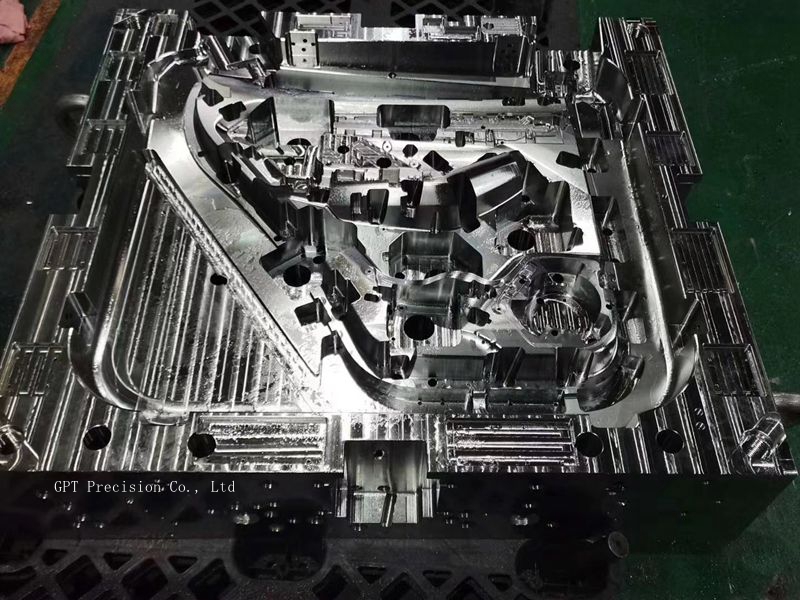

In precision injection molding manufacturing, injection molded optics present special challenges which require innovative methods to meet our customers’ demanding expectations. As today’s technical needs require ever increasing volumes of instant data transfer, the need for near-zero variation in molded optics in opto-electronic devices becomes apparent. Often times, the differentiator between a functional device and a reject is a handful of microns on a lens center location.

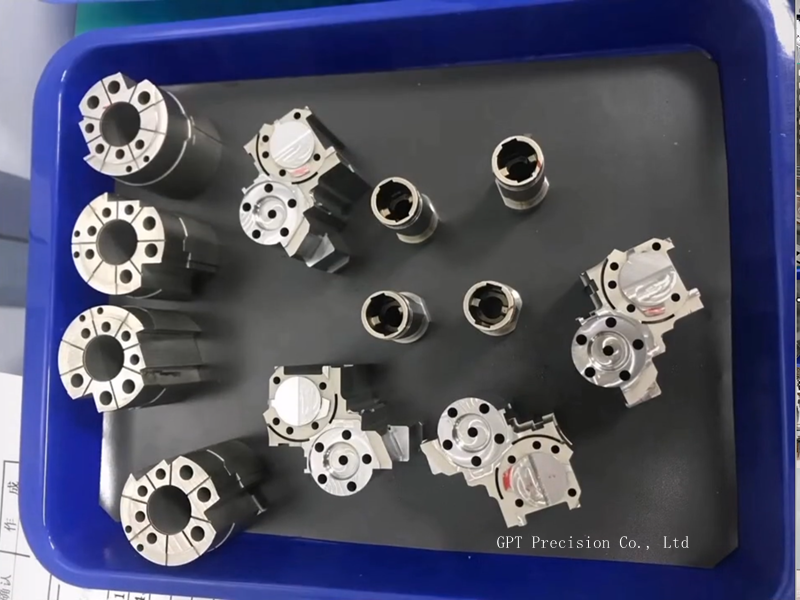

we have refined our polymer molding capabilities over the years – moving from integrated lenses to micro lens arrays, light pipes for military and medical applications and molded prisms for imaging. Specialized mold designs with replaceable optical mold inserts and carefully developed and controlled molding processes ensure the highest quality molded optics again and again.

Molded Optics QA

As part of the custom plastic molding process, quality control is paramount. The performance of our molded optical components is verified using custom-designed test fixtures together with our laser interferometer, laser scanning and profilometry equipment. Advanced vision machine systems are used to check for contaminants and other defects, often times in our Class 100,000 molding cleanroom. We tailor the inspection and handling of the molded optics to meet your specific requirements.

Precision injection molded plastic optics requires special knowledge and capability. Due to tight tolerances and often extreme mold processing conditions, the injection mold designs and fabrication techniques require special knowledge and skills. The injection molding equipment should have advanced control capability and care must be taken to ensure cleanliness. Plastics Optics Molding The molding process parameters (temperatures, pressures, and speeds) are unique to precision optics molding and these processing parameters are generally a closely guarded trade secret. GPT mold’s molding equipment also includes robotics, conveyors, custom degaters, thermolators, vacuum loaders, and dryers.

Recent examples of lenses molded at GPT mold includes: freeform lenses for LED lighting, precision laser collimating lenses, CMOS imaging lenses for robotics and medical devices, eyepiece optics, integrating tunnels, TIR lenses for LED illumination, freeform prisms, fresnels, and a variety of lens arrays. The engineers at GPT mold Optics are experienced in when and how to take advantage of molded plastic optics.

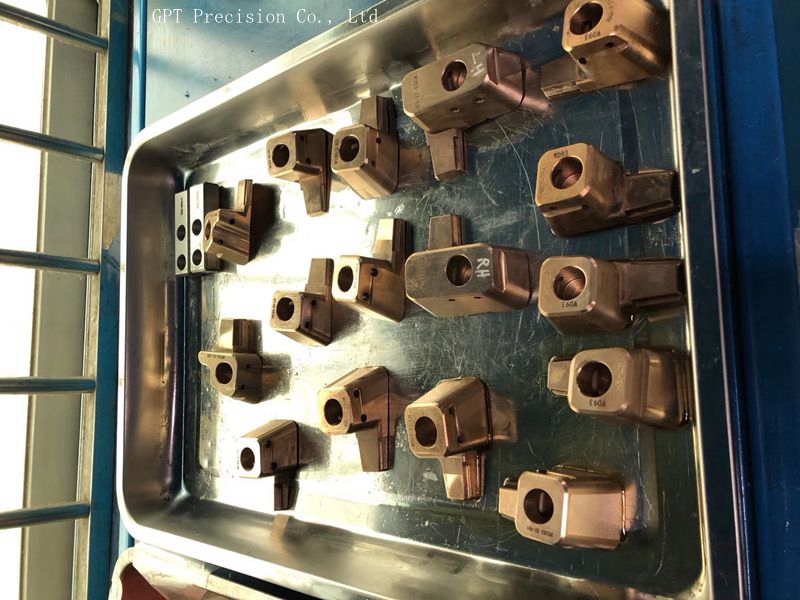

Precision Mount Parts and Injection Molds

With in-house Machining Centers, CNC Lathes, Wire EDM, CAD/CAM software, and experienced machinists and toolmakers, GPT precision mount parts and injection molds.

In order to carry out our mission of providing turnkey optical product development and manufacturing services, GPT mold has invested heavily in CNC machining capability. This includes a high precision GF Mikron vertical machining center with glass scales and advanced thermal control, GF Agie Charmilles Wire EDM capable of holding micron tolerances, Hardinge CNC turning center for precision lens barrels, two Mazak machining center, Prototrak and Haas CNC mills, and FlashCut CNC tabletop mill and lathe. In addition, GPT mold has a complete set of manual machine tools. CNC Machining Equipment alone is not sufficient. GPT mold’s staff includes talented and experienced machinists and toolmakers, each with an average of 15 years experience. GPT mold’s advanced machining capabilities are a critical part of our ability to rapidly and cost-effectively develop new optical products.

We look forward to demonstrating how our polymer know-how and capabilities can provide a winning and world-class solution for your optical project needs.