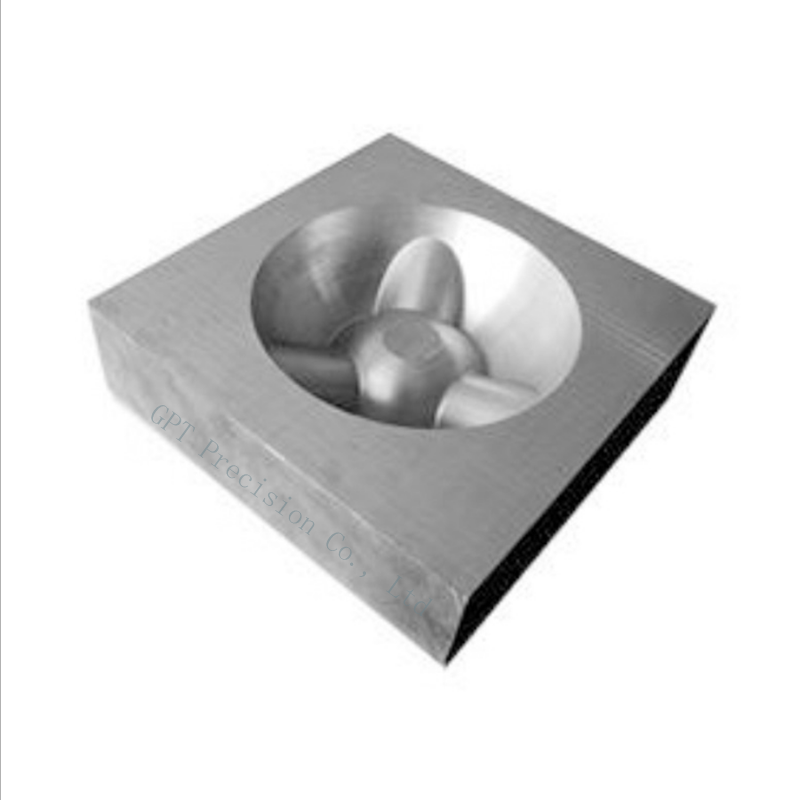

CNC Machined parts

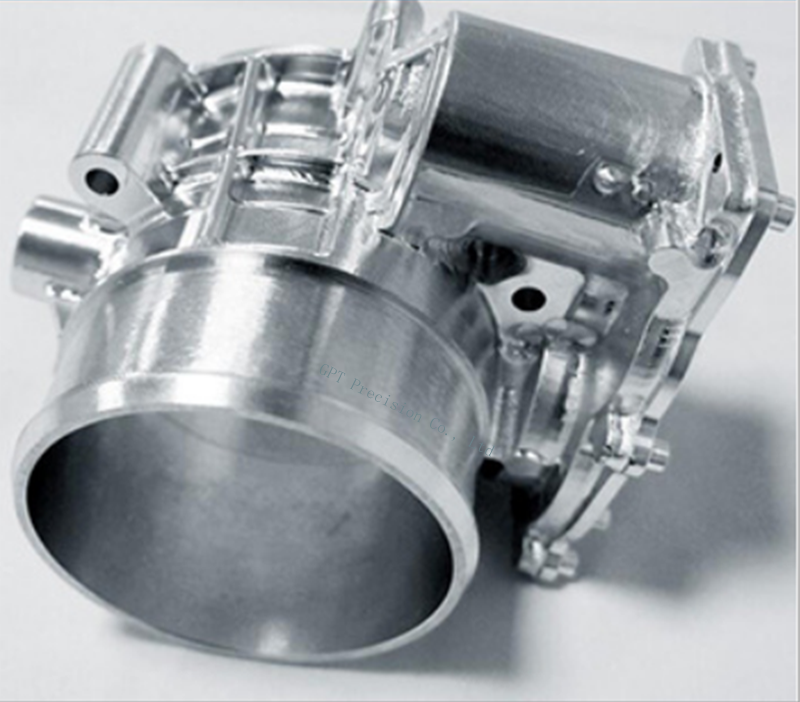

CNC Machining Aluminum Housing Part

Get Latest Price

Min. Order / Reference FOB Price

Port: Shenzhen, China

Production Capacity:10000

Payment Terms: L/C, T/T, D/P, Paypal, Western Union

Surface Treatments: Polishing, Anodizing, Painting, Silk Print, etc

Material: Aluminum

Transport Package: Inner Box/Carton Box/Wooden Box

Specification: depend on inquiry

Trademark: GPT Precision

Origin: Shenzhen China

- Specifications

CNC Machining mill Services and Turning Services – Top China CNC Turn-Mill Parts & Products Manufacturer

GPT Precision Co., Ltd is a leading CNC manufacturing company in China, providing efficient and quick CNC milling and turning services for precision machined components manufacturing and custom machining. We have sophisticated high-performance multi-axis CNC milling-turning center, accomplished workers and operators to provide quality custom CNC turn-mill parts with improved productivity and outstanding flexibility. Our CNC design and engineering team will review your drawings carefully and rigorously, then give you proper advice or start the machining cycle. You can get detailed CNC mill-turning quote fast as long as you sent your metal or plastic parts design drawings. Highly automated CNC programming will speed up and simplify the machining of CNC milling and turning components and achieve tight tolerance, smooth surface and complex geometries to meet your requirements.

CNC milling (computer numerical control milling) is a CNC machining process that involves removing material from the workpiece by rotating and moving a cutting tool, such as a milling cutter, and positioning the workpiece properly, to produce or finish a custom object. CNC milling technique can be used to shape a part from beginning to finish, it’s best to produce features or definition as a secondary or finishing process for machined components. The milling cutting tool can be placed horizontally or vertically, but since the numerically controlled milling machines have evolved strongly, moving on several axis, up to 5 axis, allowing much more to a movement of the cutting item in addition to the repositioning of the piece.