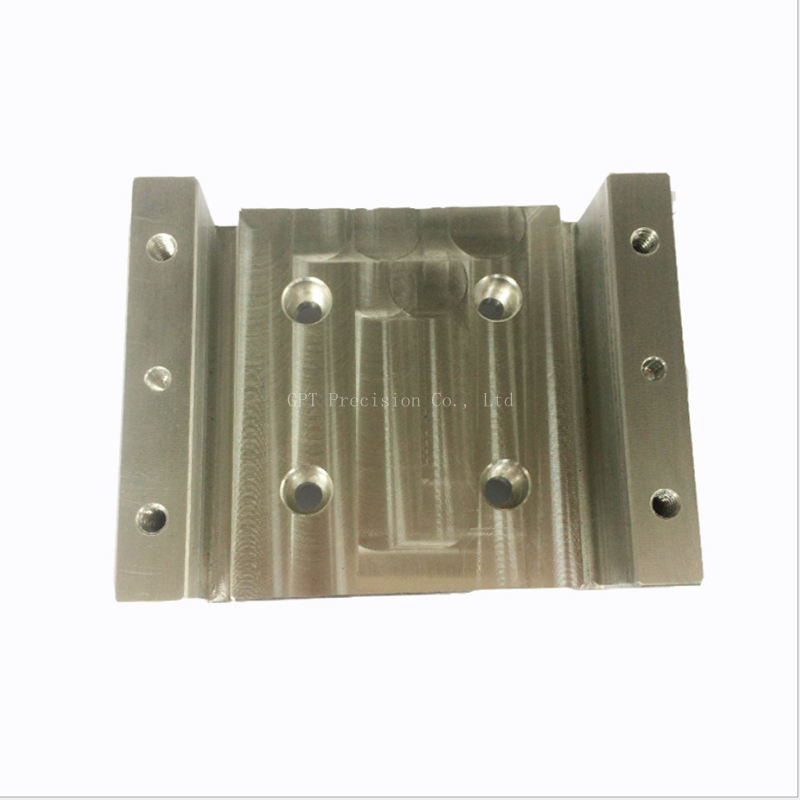

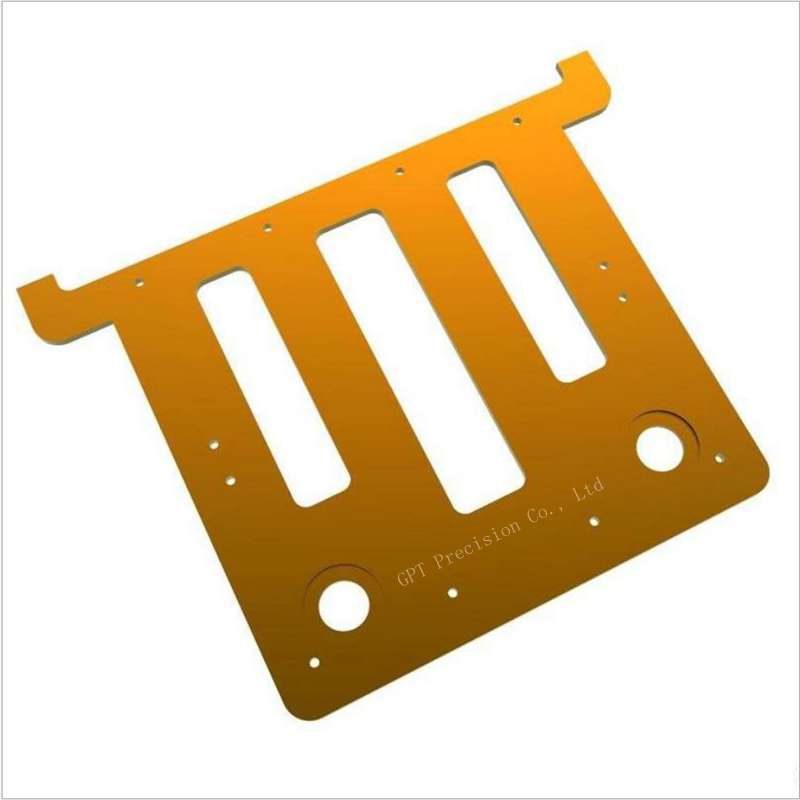

Sheet Metal Fabrication Services

Sheet Metal Fabrication

Min. Order / Reference FOB Price

Production Capacity:10000

Transport Package:Plastic Box /Wooden Box/ Carton Box

Payment Terms:L/C, T/T, D/P, Paypal, Western Union

Fabrication method: Sheet Metal Fabrication

Brand Name:GPT Precision

Color:Any Color as You Requirement

Materials: sheet metal

Place of Origin: Shenzhen China (Mainland)

Lead Time:3-7Days

- Specifications

GPT Precision Co., Ltd have fully-equipped sheet metal shop with welding, shearing, punching facilities. We also carry a large inventory of stainless steel(1-12mm), aluminum(1-10mm), and galvanized sheet (1-20mm) stock in order to continuously provide immediate service. Our custom precision Sheet Metal fabrication services offer a cost-effective and on-demand solution for your manufacturing needs.

What is Sheet Metal fabrication?

Sheet Metal Fabrication is one of the most necessary types of modern industrial manufacturing. It is the process of turning flat sheets of steel or aluminium into metal structures or products, by cutting, punching, folding and assembling. Sheet metal fabrication is used in pretty much every sort of manufacturing field, notably in medical equipment, computers, electronics and appliances.Fabrication services range from low-volume prototype to high-volume production runs with significant cost savings.

Sheet metal can be cut, bent or stretched into nearly any shape, which is generally done by cutting and burning the metal.Special tools, such as band saws and chops saws, can also be used in the Custom sheet metal stamping. These ensure even cutting throughout the process. Cutting torches are capable of cutting large sections of sheet metal with minimal effort.Sheet metal fabrications use press brakes, which ease the process of sheet metal fabrication, by helping to create sharp bends and angles within the metal. There are a variety of different press brakes, which have different functions and are used for different purposes.One of the other main factors in sheet metal fabrication is welding. Once all the components are formed, they are then assembled and tack welded into position. Many welding techniques can be used in sheet metal fabrication in order to prevent warping or any other abnormalities. These techniques include covering the metal with sand during the cooling process, special straightening process, welding in a staggered manner and using a stout fixture.Straightening defected metal can be achieved by using with an oxy-acetylene torch. Heat is applied to the metal in a slow manner to remove any abnormalities.The metal is usually metal finish processes services by being sand blasted, primed and painted. This then ensures the metal looks fantastic.