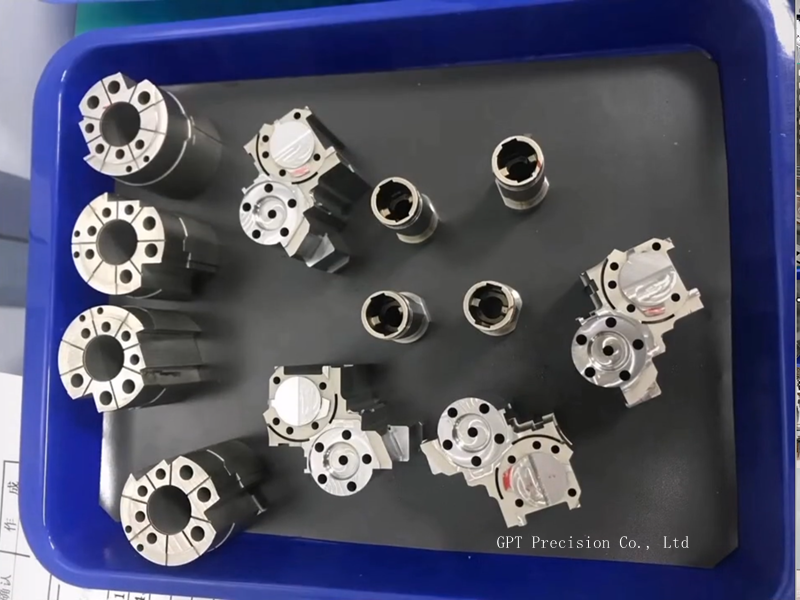

injection molding part services

precision injection molding part

Get Latest Price

Min. Order / Reference FOB Price

Port: Shenzhen, China

Production Capacity:100

Payment Terms: L/C, T/T, D/P, Paypal, Western Union

Surface Treatments: Polishing, Texturing, Sandy finish, etc.

Material: steel

Transport Package: Wooden Box

Specification: depend on inquiry

Trademark: GPT Precision

Origin: Shenzhen China

- Specifications

Precision Injection Molding Specialists

Precision injection molding is a complex process that needs a highly dependable network of machines, designers, and engineers to create the high precision quality components customers need. From parts design, mold design, materials selection and technology, Jabil’s expertise in creating optimized designs with manufacturing in mind helps create more efficient and high-quality solutions throughout all stages of a product’s lifecycle.

GPT mold has advanced our customers’ molding capabilities and accelerated product launches through effective collaboration, data-driven engineering systems, and a comprehensive, end-to-end approach. The pressures to deliver product with advanced designs to market on-time and on-budget

have increased significantly. That’s why GPT mold leverages the latest mold technologies to shave precious seconds off the manufacturing process. In high-volume runs, this leads to savings of hundreds of thousands of dollars a year.

GPT mold Precision Injection Molding Capabilities

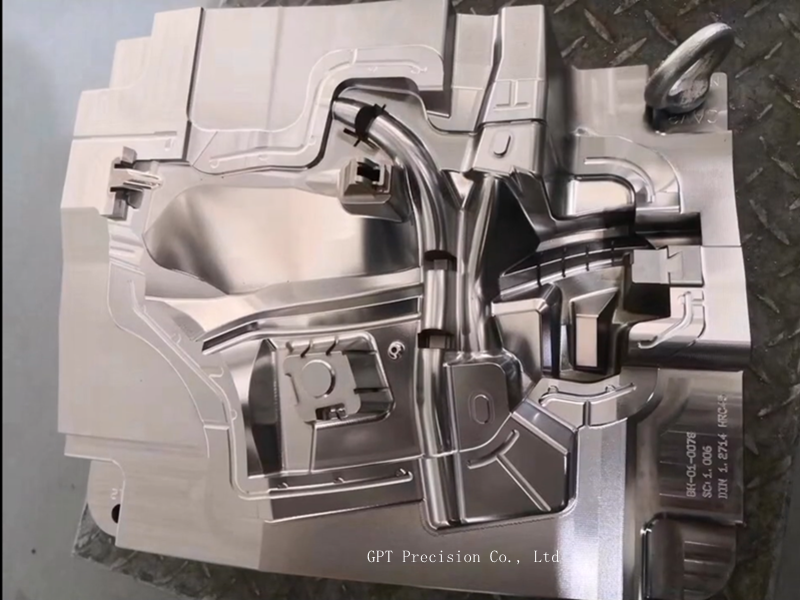

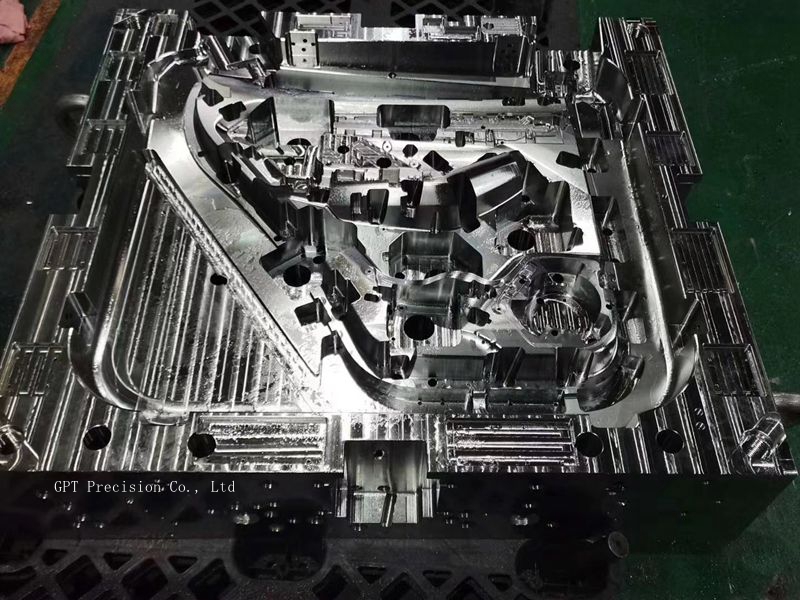

Core Competence: Expertise in precision automobile mould Manufacturing, experienced mold design and Thoroughly Project management; High efficiency lead to Competitive Price and short tooling lead time as well as customer satisfaction.

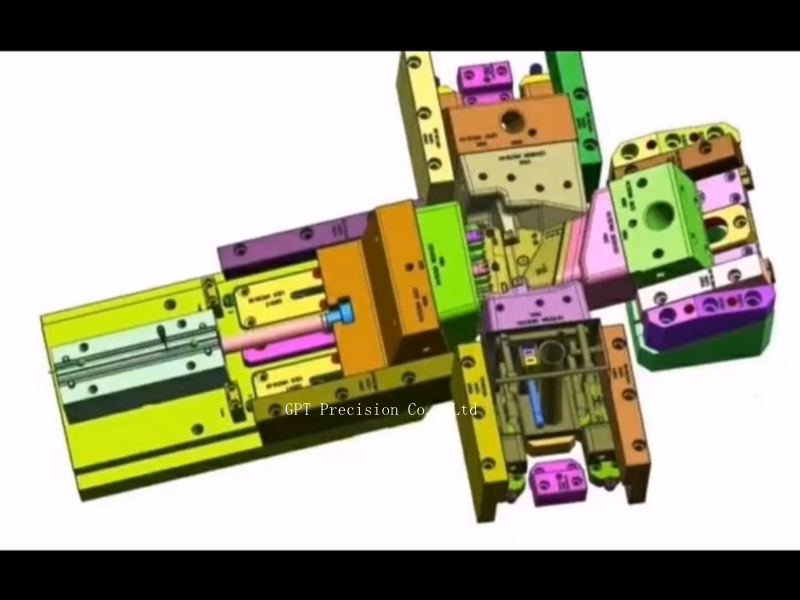

As a trusted partner to the world’s leading brands, GPT mold’s PIM technology allows for companies to create the parts and components needed to meet consumer demand with the quality and efficiency to keep customers competitive. GPT’s custom mold capabilities help build better products from ideation to commercialization:

Plastic part optimization

Mold engineering development

Mold-life asset management

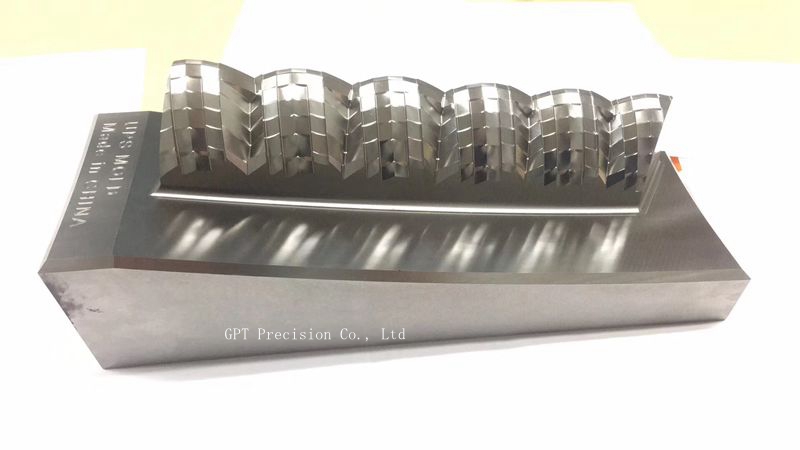

High-precision mold manufacturing

Mold qualification and plastic part validation

GPT mold expertise in precision injection molding improves the reliability and longevity of the manufacturing process, from one cavity to over 100 cavities and beyond, serving the healthcare, packaging, and consumer-electronics markets. Our team of over 150 mold-industry experts uses state-of-the-art engineering tools, machining centers, and in-machine quality systems to guarantee industry-leading accuracy and 100% mold component interchangeability. Additionally, our 3D computed tomography (CT) scanning lets us non-destructively visualize, measure, and analyze precision injection molding parts and assemblies internally and externally. This yields fast, accurate results that save our customers significant time and effort.

Sustainable Solutions

At GPT mold, we believe it is our responsibility to be good stewards of natural resources and positively contribute to global environmental challenges. We do this by managing our own environmental impacts, innovating sustainable technologies and products – and helping our customers do the same. Through reusable packaging solutions, bio-based materials, thin-wall technology, returnable packaging options, energy-efficient operations, and reduced distance logistics, we strive to do all we can to move towards a zero-waste production process.

GPT Precision injection molding services adapt readily to your evolving business and product needs, from design and fabrication through complex integration, validation, and test. Our flexible approach streamlines the entire product lifecycle, empowering you to focus on what matters most to your business — with the peace of mind that GPT mold has the rest covered. Our dedicated precision injection molding team has years of expertise and experience, giving customers access to GPT mold’s strong industry partnerships to be a leading end-to-end solutions provider for the world’s top companies.