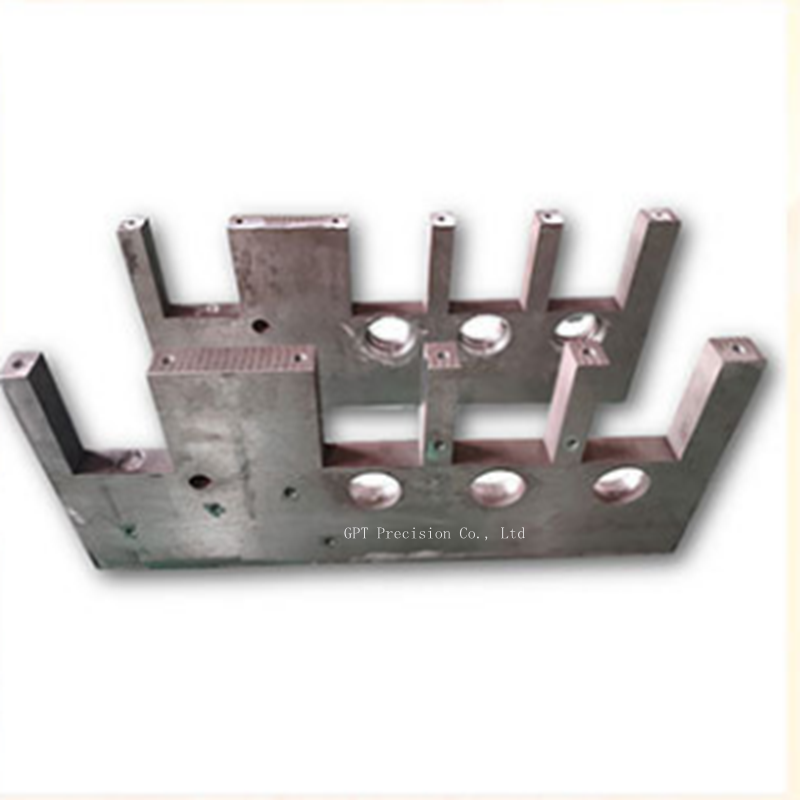

Custom CNC Machining Services

Custom CNC Machining Services

Get Latest Price

Min. Order / Reference FOB Price

Port: Shenzhen, China

Production Capacity:10000

Payment Terms: L/C, T/T, D/P, Paypal, Western Union

Surface Treatments: Polishing, Anodizing, Painting, Silk Print, etc.

Material: Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, Nylon

Transport Package: Inner Box/Carton Box/Wooden Box

Specification: depend on inquiry

Trademark: GPT Precision

Origin: Shenzhen China

- Specifications

GPT Precision provides custom machined services to engineers, product developers, designers. Our highly qualified ASD9100 machine shops can make any custom design, simple or complex. We offer rapid CNC prototypes, small-batch machining, and high-volume production, with all orders serviced by GPT Precision from end-to-end. Simply upload a CAD file to the GPT Precision Instant Quoting Engine℠ to get a price, lead time, and design-for-manufacturability feedback on your custom CNC parts. Our CNC service offers metals and plastics as well as flexible production and shipping options to meet you at the perfect price and product development stage.

Precision, Quality and Affordability at any volume

Our Modern CNC machines can handle small radius cuts and maintain a high quality level whether you want one piece or one hundred. Chamfered edges, multi radius curves, and tapped holes are a few things that make machining a part more workable for any projects. We take pride in making quality, custom, low cost, machined parts.

GPT Precision’s capabilities for Custom CNC machining; our workshop’s flexibility gives us the ability to produce tailored parts in CNC machining meeting our client’s expectations.

Finishing and applications: Our expert craftsmen will apply a high-polishing finishing to ensure a smooth surface aspect result. The latter refers to a basic finishing. However, in order to get very realistic parts, we provide a large choice of finishes such as metal plating/coating, chrome plating, anodizing or water transfer printing. We often do projects requiring perfect visual rendering, aimed at fields such as art, design or marketing. Through the adjusted sandblasting process, we can make Mold-tech texture finishes. To finish, our workshop offers several applications for prototype CNC machined parts, such as tapped holes and heli-coils.

Materials: Our custom CNC machined processes and capabilities include plastic material machining and metal machining. Indeed, we are able to manufacture materials such as ABS, POM or Nylon when it comes to plastics and brass, aluminium or stainless steel regarding metals.

Our team also offers a variety of other machining services to take your unique project all the way from conception to realization with help from our expert engineers. In addition to providing conventional milling, drilling, turning, and sawing, we are well-equipped for the specialty grinding and part-marking processes required by many modern applications. And, if needed, our certified partners can provide heat treating, welding, plating, and painting services before final inspection, assembly, and packaging. This comprehensive package of services helps ensure cost certainty for all of our clients, as well as quality control that competitors simply can’t match.

Our cutting-edge Swiss screw machines are well-suited to fabricating difficult pieces, such as custom precision medical machined parts,long parts, custom complex machining parts with a variety of functions in a single setup, and high-accuracy parts with strict tolerance requirements. For these high-precision components, GPT Precision utilizes electrical discharge machining (EDM). EDM makes use of a thin, electrically charged wire to erode small volumes of material in order to create the desired shape. The ability to cut fine part features into hardened alloys makes EDM particularly useful for fixtures, inspection gauges, and other profile or contour work.

Our advanced turning centers allow for rapid delivery of prototypes, flexible order quantities, reduced tooling costs, and tighter tolerances than traditional machine work, all backed by our skilled engineers. In addition to our standard vertical milling machines, we work with horizontal milling centers for larger runs; this equipment can operate at higher speeds and allows us to optimize for cost-efficiency when needed.