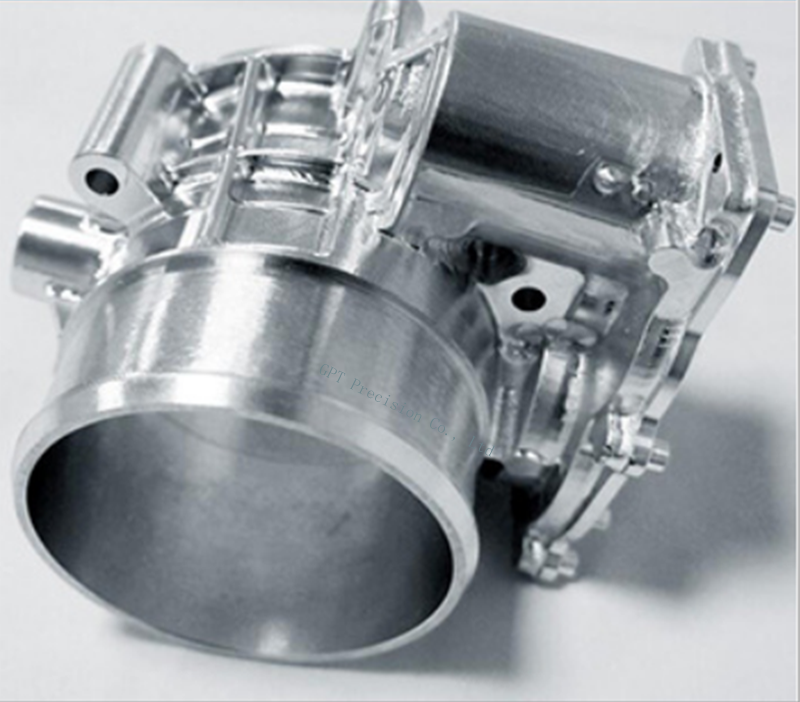

OEM Precision Turned Parts

Process type: CNC turning, milling, drilling, grinding, wire EDM cutting etc.

variety of materials :automatic steel, stainless steel, hardened steel, aluminium, brass, bronze, plastic etc. diverse processing and finishing: quenching and tempering, hardening, sharpening, polishing, nitriding, carbo-nitriding, zinc plating, nickel plating, protecting with Zn/Ni/Ni galvanic plating, TiAn plating etc

Color: As customers' request

Standard: GB, EN, API650, China GB Code, JIS Code

Tolerance : 0.01-0.05mm can also be customized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

Port: Shenzhen China

Delivery time:7-30 days after receive the pre-payments

- Specifications

Introduction to CNC turned parts Machining Technology

CNC precision turned machining is a traditional way of cutting off excess material by division. CNC processing speed, low cost, processing materials with high strength, high temperature resistance, high toughness, and even transparent and other requirements; Moreover, the post-processing mode of CNC model is not limited to one pattern, such as grinding, powder spraying, painting, polishing, silk screen printing, electroplating, etc., whose effect can be completely comparable to or even higher than the samples produced by the mold. In appearance, assembly, functional verification can be hit to the customer's final design intention. Therefore, CNC model making has become one of the mainstream of modern hand plate processing.

CNC turned precision sample processing method: generally, the workpiece is processed on both sides, and under special circumstances, the workpiece will be processed on three sides, four sides, five sides or six sides. In the processing process, we will retain the surrounding frame viscose water on the workpiece, fix the workpiece with the frame bone pulling, and position the workpiece with gypsum inverted, so that there will be no bonding effect between the workpiece and CNC workbench to better ensure that the processed workpiece will not be deformed and the material level of the workpiece is accurate. In addition, gypsum is an indispensable auxiliary material in hand plate processing.In the process of turning over, the cavity has been hollowed out, and the wall thickness of the product is generally relatively thin, so the thin wall shake phenomenon will occur in the processing, which has a great impact on the appearance of the product. After filling gesso is equivalent to added prop, this will make when processing won't appear thin wall jitter, assured processing effect.

Precision CNC Machining.Also known as machining is a process that uses rotary cutters to shape material in a way that will benefit the end user. In most cases, this is a process that removes material from the stock in order to produce the necessary part.