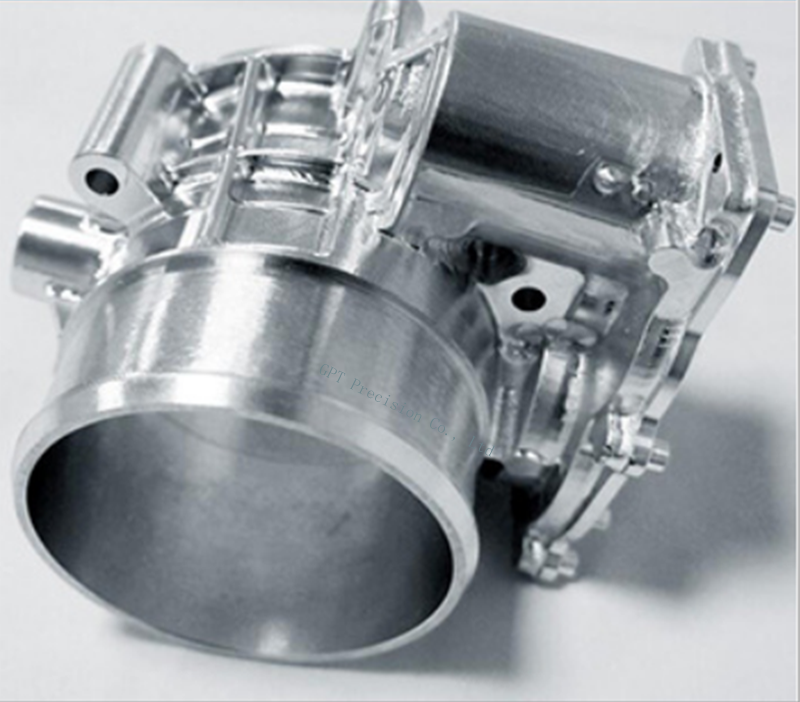

CNC turned Precision spare part

Process type: turning, drilling, milling, growing , tapping, thread turning etc.

variety of materials :automatic steel, stainless steel, hardened steel, aluminium, brass, bronze, plastic etc.

diverse processing and finishing: quenching and tempering, hardening, sharpening, polishing, nitriding, carbo-nitriding, zinc plating, nickel plating, protecting with Zn/Ni/Ni galvanic plating, TiAn plating etc

Color: As customers' request

Standard: GB, EN, API650, China GB Code, JIS Code

Tolerance : 0.01-0.05mm can also be customized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

Port: Shenzhen China

- Specifications

Precision CNC turning parst machining remains an essential service utilized in creating parts, components of many tools and items we use and depend on in everyday life. In fact, China CNC turning machined supports technology where visionary companies are supporting advanced efficiencies on older technology and also creating hardware supporting the very latest developments in technology. But what exactly is precision machining? Here we take a closer look at what precision machining is and how it is utilized to support advances in modern manufacturing.

WHAT IS PRECISION turned MACHINING?

Precision turned machining is a type of technical manufacturing that is essential in creating and designing machines, parts(CNC turning brass parts), tools, and other hardware that are essential in modern manufacturing to maintain process controls and tolerances that function under extremely tight specifications. It is used to make up the many large and small objects and their components that we use in everyday life. If an object is made up of many small parts, these will often need to be made with precision machining to ensure they fit together precisely and function properly. precision machining can be defined as utilizing the highest function of a tool, program, engineering talent or equipment thus pushing the limits of design feature creation and materials science and performing these operations under the tightest tolerances defined by any sub-set of these manufacturing parameters. Obviously, precision machining has evolved over time, and advancements in all related technologies help push the limits that define precision machining and improve performance consistently. The real art in precision machining comes with the marriage of computer controlled design and human engineered design for the creation of unique features and highly controlled output and functionality driven by advancements in fluid dynamics, chemical control, mechanical, climate extremes and durability required in modern hardware technologies. Precision machining is particularly important to create tools and parts in a way that is precise, stable, and can be repeated with consistency, accuracy, and durability.