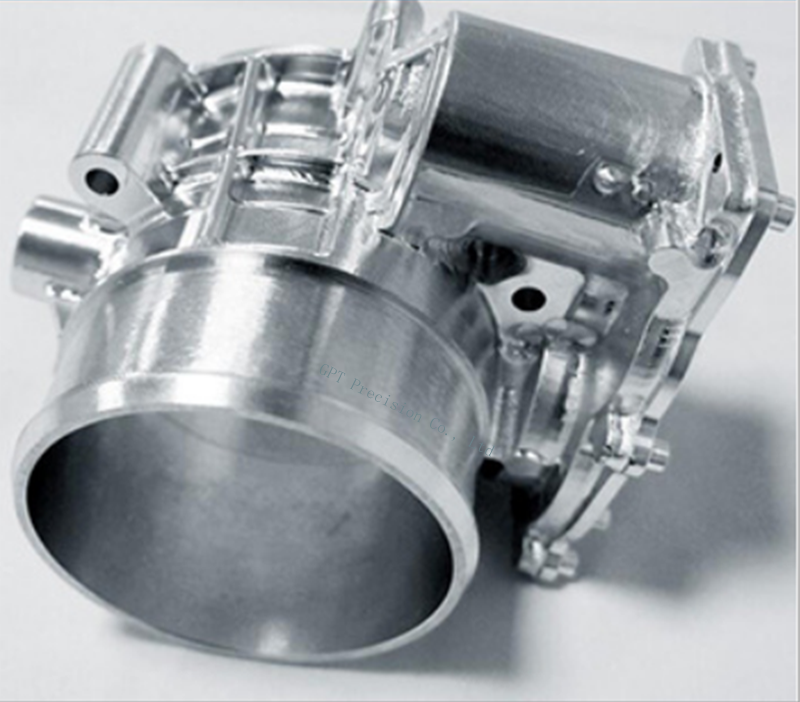

CNC milling services

Material:Stainless steel, mald steel ,zinc alloy ,aluminium alloy,brass ,bronze ,copper ,etc.

Process type: Turning,milling,grinding,lathe,boring,drilling,punching,tapping,wire-electrode-cutting,

machining center, etc.

Surface treatment: Sand blasting, polishing, brush, Anodized

Dimension: As customers' request

Tolerance: 0.01-0.05mm can also be customized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

Applications: Auto parts, Home hardware, Luggage accessories, Machine accessories, chassis, fuel tank, radiator, boiler drum, container shell, bicycle parts, office machinery, etc.

- Specifications

CNC Machining is a process used in the manufacturing sector that involves the use of computers to control machine tools. Tools that can be controlled in this manner include lathes, mills, routers and grinders. The CNC in CNC Machining stands for Computer Numerical Control.

Under CNC Machining, machine tools function through numerical control. A computer program is customized for an object and the machines are programmed with CNC machining language (called G-code) that essentially controls all features like feed rate, coordination, location and speeds. With CNC machining, the computer can control exact positioning and velocity. CNC machining is used in manufacturing both metal and plastic parts.

First a CAD drawing is created (either 2D or 3D), and then a code is created that the CNC machine will understand. The program is loaded and finally an operator runs a test of the program to ensure there are no problems. This trial run is referred to as "cutting air" and it is an important step because any mistake with speed and tool position could result in a scraped part or a damaged machine.

There are many advantages to using CNC Machining. The process is more precise than manual machining, and can be repeated in exactly the same manner over and over again. Because of the precision possible with CNC Machining, this process can produce complex shapes that would be almost impossible to achieve with manual machining. CNC Machining is used in the production of many complex three-dimensional shapes. It is because of these qualities that CNC Machining is used in jobs that need a high level of precision or very repetitive tasks.

we could reach very tight tolerances,0.001mm is possible for us.

Specializing in metals such as aluminum, steel, and titanium, we are also adept at working with nickel, magnesium, and other exotic alloys. We also have the capability to manufacture from various raw material types including bar stock, castings, forgings, and sheet metal. Secondary services include assembly, welding (fusion/resistance), fabrication, epoxy painting, cleaning, hot forming, and EDM. We offer fluorescent penetrant and magnetic particle inspection and have several coordinate measuring machines for detailed inspection.

GPT Precision Co., Ltd has earned its reputation for manufacturing the highest quality custom machined parts for our customers and is committed to providing each customer with a custom solution for their application. Call today to see how we can help you.