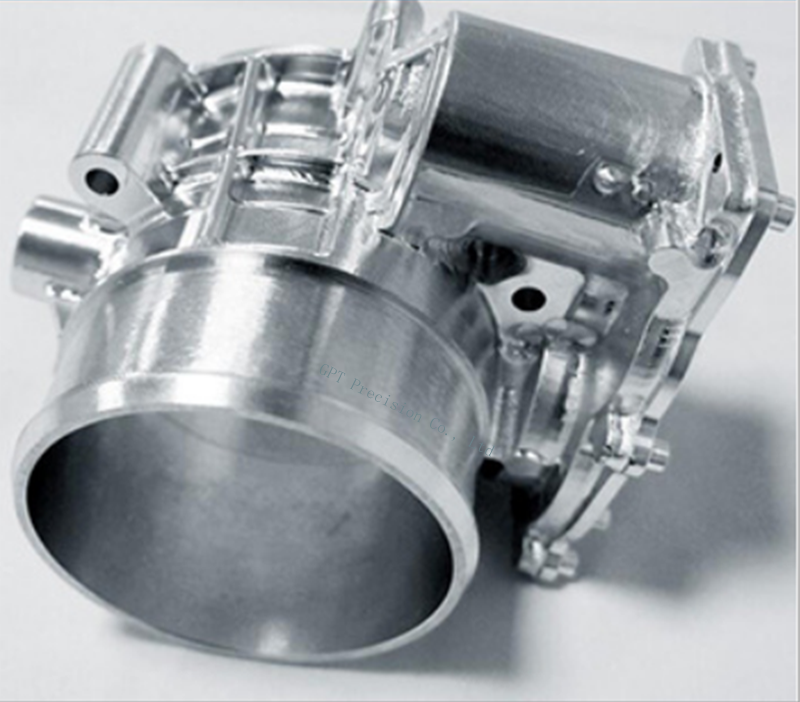

CNC lathe China Services

Port: Shenzhen, China

Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram

Application:Auto and Motorcycle Accessory, Machinery Accessory, Medical

Standard: GB, JIS Code, TEMA, ASME

Surface Treatment: Zinc plating, chrome palting ,nickel plating ,painting ,sand blasting ,powder coating ,polishing ,anodized ,baking finish ,oxidation ,electroplate ,passivate.

Production Type: Batch Production

Machining Method:CNC lathe Machining

Material: Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, Nylon

- Specifications

Advantages of Our Chinese CNC lathe Services

High efficiency: We can produce 1-1000 CNC milling and as fast as one day with our equipment.

Excellent Precision: Based on customer demands, GPT will provide precise and accurate measurement and production for each product.

Exact Specifications: Automatic CNC milling-turning center will perform the designed motions to get required parts with exact sizes, shapes and other parameters.

Competitive Prices: With advanced CNC turning machining services and increased productivity, we can bring you the most cost-effective and affordable custom solutions.

Quality Guaranteed: Carefully picked raw materials and strict quality control system throughout the whole project, ISO9001:2015 certification.

Fast Delivery: Average 7 days turnaround time and 99.85 on-time delivery rate.

What is CNC Milling and Turning Service (CNC Turn-Milling Compound)

CNC turning or CNC milling allows to manufacture CNC parts in single handling, while CNC milling-turning is a compound machining technology, to execute designed multiple kinds of tasks with the computer numerical control when the cutting tool and workpiece are both rotating. With CNC milling and turning services, complex curved or special-shaped parts can be produced through the processing of multiple surfaces on the CNC milling-turning center. CNC turn-milling machine can reach any surface of the components. Most of the CNC turn-milling compound process can be completed on the CNC turning center. There are two different CNC turning-milling types:

Contour machining when the workpiece is parallel to the cutter axis

Surface machining when the workpiece is vertical to the cutter axis.

Features of CNC Milling and CNC precision Turning

Shorten manufacturing process chain and higher efficiency

Reduced clamping times and improved machining accuracy

Free-moving worktable and high precision built-in spindle

Mainly for mass production of small parts or complex components in high speed and diversified processing.

Designed parts can be produced in one-time processing

Suitable for cutting copper, iron, aluminum, stainless steel, brass, plastics and more materials.

More precise products, faster speed and decreased cost than single machining