What is CNC Engraving?

April 16, 2014

Engraving is the art of carving a design into a hard surface.CNC engraving is a computer-controlled method of cutting designs into metal and plastic surfaces. Applications of engraving include logos, text, serial numbers, QR codes and more.

Types of Engraving

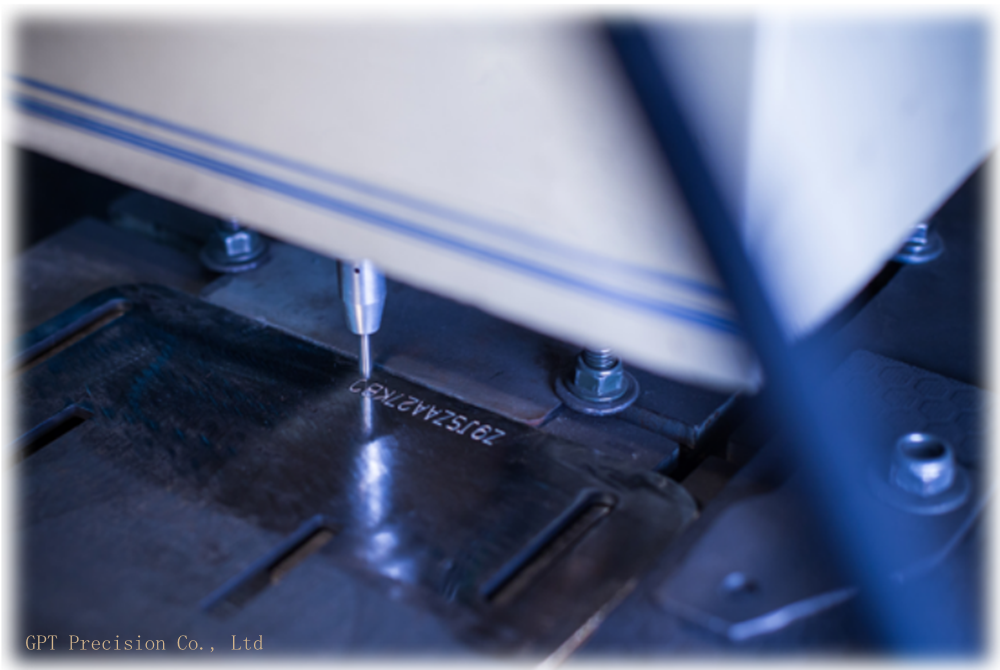

Dot peen engraving, also known as “pin marking,” is performed utilizing a probe that rapidly indents dot-shaped marks into a surface.

Laser engraving is often confused with laser marking. The two differ with engraving removing material while marking is using a laser to leave marks via color change, charring, melting and more.

Most CNC mills used for part production can also engrave when equipped with an engraving endmill.

CNC Engraving is one of the most interesting and artistic things you can do with a CNC. In this guide, you’re going to learn everything you need to know to tackle your own CNC engraving work.

Sometimes CNC engraving is purely utilitarian, for example to add a serial number to a part. Other times it is an artistic embellishment. The type of CNC Engraving Machine you have will determine most of what’s needed to engrave.

Many materials can be cnc engraved by laser including:

Wood: The laser carbonizes or burns many natural materials like wood and leather.

Leather

Plastic

Metals: Metal requires a lot more power and sometimes specific laser types that operate a frequencies that work more efficiently with metal.

Coated Materials: Sometimes it’s easier to engrave with a laser that burns away or discolors a particular coating. There are specialty coatings made for exactly this purpose.

Engrave your custom parts with GPT Precision Co., Ltd’s engraving service. Request a quote, or design engraved parts with GPT Precision Co., Ltd’s CAD.