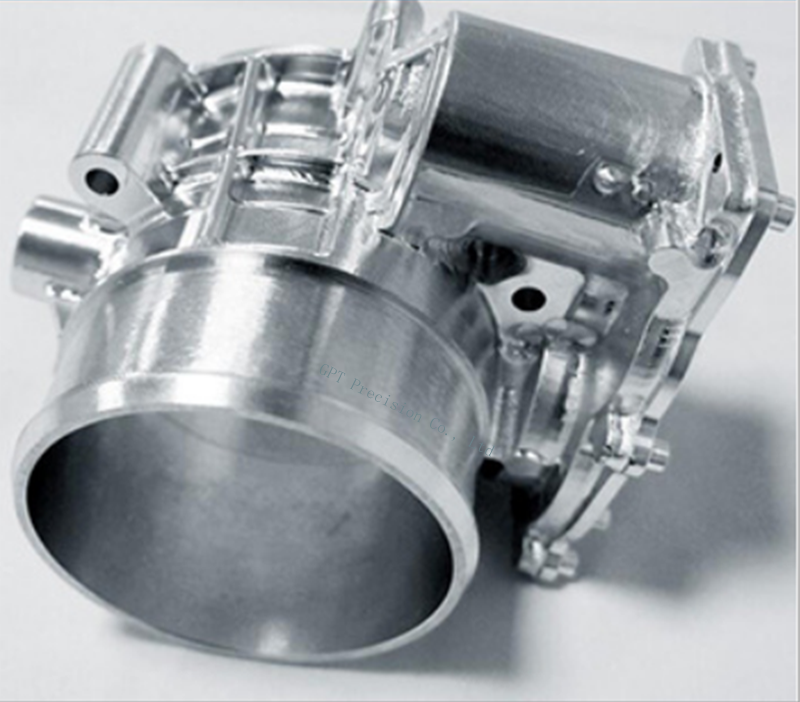

China CNC turning spare parts service

Technique: Turning, drilling, milling, planning, boring. Grinding, gear-hobbing, wire-cutting, sawing, reaming, screwing, EDM machining, assembling and etc.

Precision: Average level: ±0.01mm, depending the part size and thickness and material

Quality System: 100% inspection(offer QC report)

Color: As customer's specific requirements

Process type: Stamping Surface treatment: Sand blasting, polishing, brush, Anodized

Standard: GB, EN, API650, China GB Code, JIS Code

Material: Stainless steel, mald steel ,zinc alloy ,aluminium alloy,brass,bronze,copper,etc.

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

Origin: Shenzhen City, China

Delivery time: 7-30 days after receive the pre-payments

- Specifications

There are many types of CNC turning operations for CNC turning parts services can be performed on a live tooling lathe in CNC turning factory, including Hard turning, Parting, Facing, Boring, Reaming, Taper turning, Drilling, Knurling, Threading, Grooving,Cold Forging etc., comes in varying tools, cost and set-up time.

Tapered turning: produce a cylindrical part of which diameter decrease from one end to another.

Hard turning: suited for materials with a Rockwell C hardness greater than 45, typically performed after heat treated.

Spherical generation: create a spherical finished surface, turning around fixed rotary axis.

Facing: a turning operation in which the workpiece is machined to its center.

Parting: create deep grooves that remove a completed or part-complete component from its parent stock.

Grooving: similar to parting, but only cut to a specific depth from outside or inside of workpiece.

Drilling: remove materials to drill holes from the inside of a workpiece with drill bits held stationary in the tail stock or tool turret of the lathe. Boring: enlarge or smooth an existing hole.

Knurling: cut serrated pattern onto the surface of workpiece with knurling tool, to change or enhance visual effect or hand grip.

Reaming: remove a small volume of materials from a drilled hole, for highly accurate diameters.

Threading: turn standard and non-standard screw threads, generally means single-point threading.

Polygonal turning: non-circular forms CNC machining operation without interrupting the rotation of the raw material.

CNC Turning Materials – Materials Used for CNC Lathes

CNC turning service can be applied on a wide variety of materials, including metal, plastic and wood. Different lathes are needed for turning metal and wood. According to the types of materials machined, certain maintenance and safety precautions may be required for the lathe. Here are some common materials for CNC turning manufacturer as below.

Metals: aluminum, magnesium, steel, stainless steel, brass, copper, bronze, titanium, nickel alloy, etc.

Plastics: nylon, polycarbonate, POM, ABS, etc.