precision Machining Parts

Precision machining is a subtractive process used in cases where material needs to be removed from a raw product to create the finished product. Precision machining can be used to create a wide variety of products, items, and parts for any number of different objects and materials. These parts usually require tight tolerances variation from nominal dimensions and from part to part, which means that there is not much room for error in the production of the piece. Repeatability and well-controlled tolerances are hallmarks of precision machining.

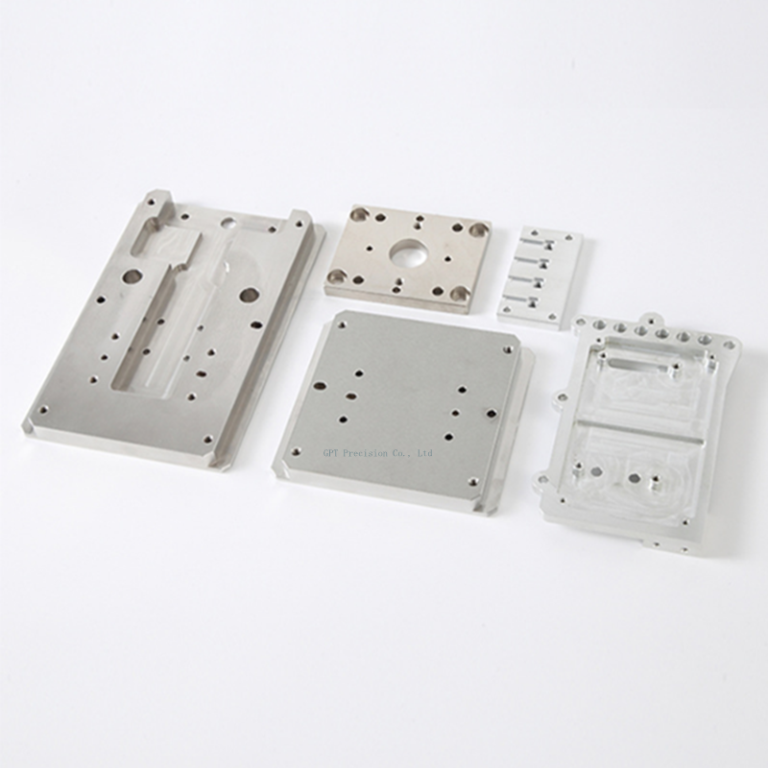

Components, parts and finished durable products that are designed to maintain extremely tight tolerance margins and a high degree of durability are essential and common drivers for utilization of precision machining. For example, parts that need to work together as part of a machine may need to always align within a certain margin of 0.01mm to 0.05mm. Precision engineering and machining help to ensure these parts can not only be made precisely but can be produced with this level of accuracy over and over again.

Precision CNC machining can be used with a number of raw starter materials including (but not limited to) plastic, ceramic, metal, composites, steel, bronze, graphite, and glass. In order to make precise cuts and intricate removal of the raw material, a combination of tools may be used.These tools vary depending on the raw material.Frequently used tools include precision CNC milling machines, precision CNC turning, Electric Discharging Machine (aka. EDM’s), saws, and grinders.Most commonly used manufacturing equipment is computer controlled heavy machinery that is designed and utilized to remove substrate material creating finely detailed components and piece parts.

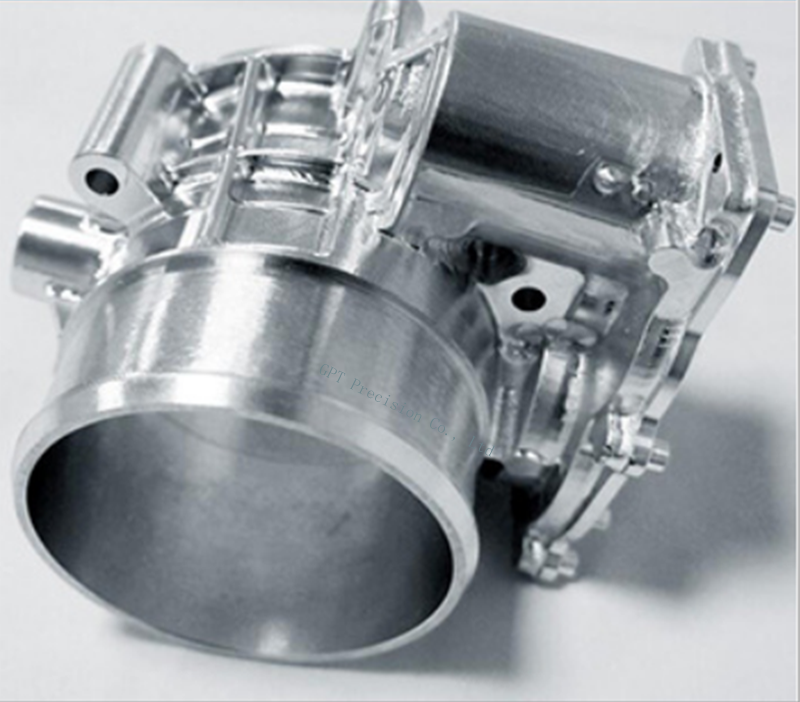

Precision machined parts often require intricate features and require precise specifications. These parts may include CNC milling

precision CNC mill,CNC turning,threads, holes, grooves, or tapers that must provide an exact fit with other components.

Precision machining is typically used to produce metal parts that require precision for the product to function properly. For example, the components that make up an automobile engine require precise specifications for optimal performance.

There is less room for error, requiring machinists to use specialized equipment for a closer tolerance. By using computer numerically controlled machines (CNC machines), lathes, and presses, our team manufactures a wide range of intricate metal parts that require keen attention to detail.

The Precision Machining Process

The precision machining process often starts with an initial sketch, which is rendered using computer-aided design (CAD) software. Engineers use CAD software such as AutoCAD to create a 3D diagram of a hand-drawn sketch.

Machinists may then enter the design into computer-aided manufacturing (CAM) programs or CNC machines. Computers automate the removal of material to produce precise parts.

Precision machining processes allow for greater accuracy. Each cut is completed by a machine that receives instructions from the computer software.

Precision machining is a vital part of the production of components that you likely use every day. The auto, electrical, electronics, medical, and aerospace industries all rely heavily on precisely machined parts to produce products that meet quality and safety standards.

Precision machining can be used to design tools, precision aluminum products, custom precision medical machined , High Precision Laser Cutting parts and other essential hardware.These parts require a tighter tolerance to ensure a proper fit with other components.

Precision machining is also useful as a means of maintaining consistency when mass-producing components. This is especially common when producing things like fittings. Precision machined parts manufacturers ensure repeatable, consistent results.

GPT Precision has delivered high-quality precision machining to customers in a wide range of industries. We can provide a custom quote based on your specific requirements. Our engineers can also help determine the specifications for your project.