CNC Rapid Prototype Service

Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram.

Application: Auto and Motorcycle Accessory, Machinery Accessory, Medical

Standard: GB, JIS Code, TEMA, ASME

Surface Treatment: Spray Paint

Production Type: Batch Production

Machining Method: CNC Milling

Material: Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron

Port: Shenzhen, China

- Specifications

- Packaging

- Others

- Our Company

Available materials:Metal--Aluminum,Copper, Brass, Stainless Steel Sheet Metal.

Plastic--ABS, PC, PV, PMMA, POM, PA(NYLON), RUBBER,Silicone

Other--Rubber, Silicone, Foam, Resin, etc

Core and cavity material: 718, 718H, S136, NAK80,P20, SKD61, etc

Process :Design moulds→CNC→Manual processing→polish→painting(surface

finish)→finish→inspection→confirmation→package

Main processing equipment: CNC, wire cutting, Grinding machine, Lathe,

Drill Press, EDM center

Detection Equipment:Hexagon CMM, TESA Height Gauge, Two dimensional

image measuring instrument,Projector, Micrometer,etc...

Team work: Specialized sales and Experienced engineers working together, controlling the whole production quality.

QC System:100% Inspection before shipment

Practicable software: Pro/engineer, Solidworks, UG, AUTcad,DRW.

Format:DWG, PDF, IGS, STEP, SLDPRT, SLDDRW, PRT, DRW, DXF,X_T,etc...

Lead time: 3-7days,depend on products and quantity.

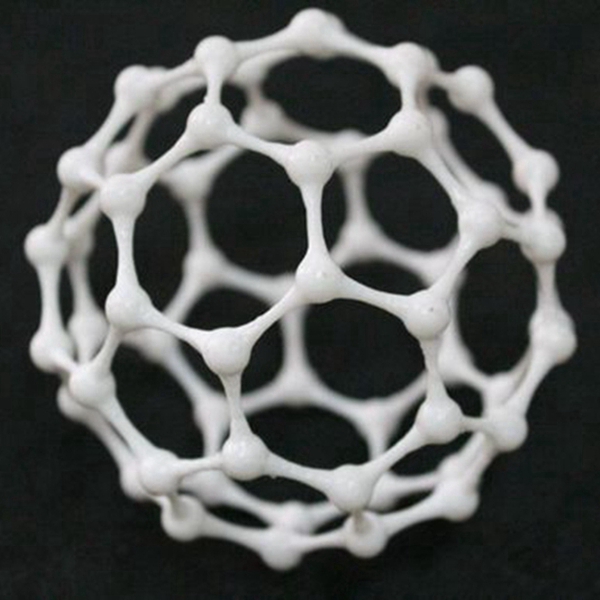

Available rapid prototyping processes: Prototype design, CNC rapid

prototype, 3D Printing service SLA/SLS prototypes, Silicone mould

and vacuum casting(Rapid Tooling)

Main Business range: 1.Auto parts: dashboard, car lamp, bar, car door,

motorcycle, scooter, bike and etc.

2.Medical decives, B Ultrasound scanner case,Ultrasonic diagnostic imaging care, and etc.

3. Electronic, digital camera,mp3/mp4,coffe oven,hair dryer, LED light case, television,

calculators, GPS electronics, DVD/VCD player and etc

4.Household appliance: Cooker, air conditioner, TV,fan, shower, fridge, coffee machine and etc

5.Kitchenwares,crafts,perfume bottle ,lighter,kitchenware ,cookie molds, and etc.

6.Telecommunications: micro phone, speaker, monitor case, computer and Etc.

7.Toys,game handle/controller, toy plane and etc.

surface treatment : Paint, polish, silk-screen printing, anodize,

transparent surface, translucent surface, brush,rubber oil, electroplate

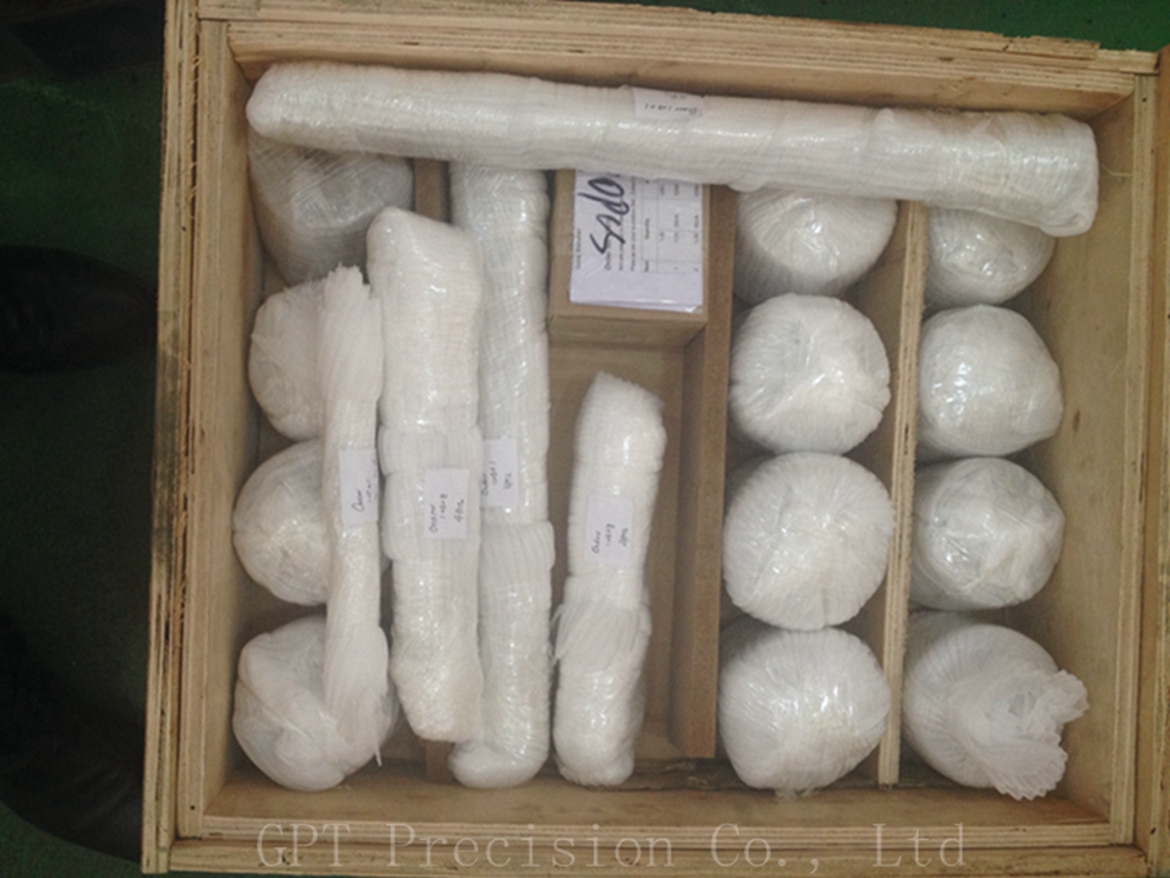

Packing:1. Prevent from damage.

2. As customers' requirements, in perfect condition.

Note: All parts are custom made according to customer's drawings or

samples, no stock.If you have any parts to be made, please feel

free to send your kind drawings/samples to us.

Our Safe Packing:

First, all the material we used is 100% real. We could supply the material certificate and SGS report, also together with the raw material for checking.

After samples approved, before packing and shipping, all the parts will be 100% inspected by our QC.

In the shipping stage, we will track the shipment including the air ship and sea ship, and then inform our customers pay attention to them.

Finally, once the customers received the goods, if there is a quality problem, no worry, show us the evidence and we will stand behind our customers for forever. Because we are seeking the long-term cooperation,Feedback and visiting from our customers.

There are two main materials for 3D printing, namely SLA and SLS, both of which are the raw materials for rapid prototyping of 3D printing.Different materials have different application characteristics. Choosing the right material is the premise of making a good product. Next, the basic characteristics of relevant materials are introduced for easy selection:

SLA material: high temperature resistance of about 40 ℃;The appearance of the product is bright and can be directly colored or primary color;The reference range of high accuracy is 0.05mm to 0.08mm.Mainly used in product appearance accessories, assembly decoration parts, toy models, car dolls, crafts, architectural models and other models with higher appearance requirements;

SLS material: high temperature resistance of about 150 degrees Celsius;The product appearance is general, relatively rough, high strength, strong structure;Applicable product precision reference range 0.1mm to 0.2mm;Mainly used in power tools, functional test accessories, internal parts of products without appearance requirements of the product accessories;

1. 3D printing is usually realized by digital technology material printer.

2. Compared with traditional manufacturing techniques, 3d drawing and precise and Rapid Prototyping printing of special materials are more accurate and faster than original techniques.

3. Solved the problem of 3D 3D complex model making that could not be completed by original manual technology.

4. Realize complex reality printing for art creators and bring physical reference experience for dream designers.

5. It brings fast, efficient and accurate convenience for the traditional handboard industry and model grinding tool industry.

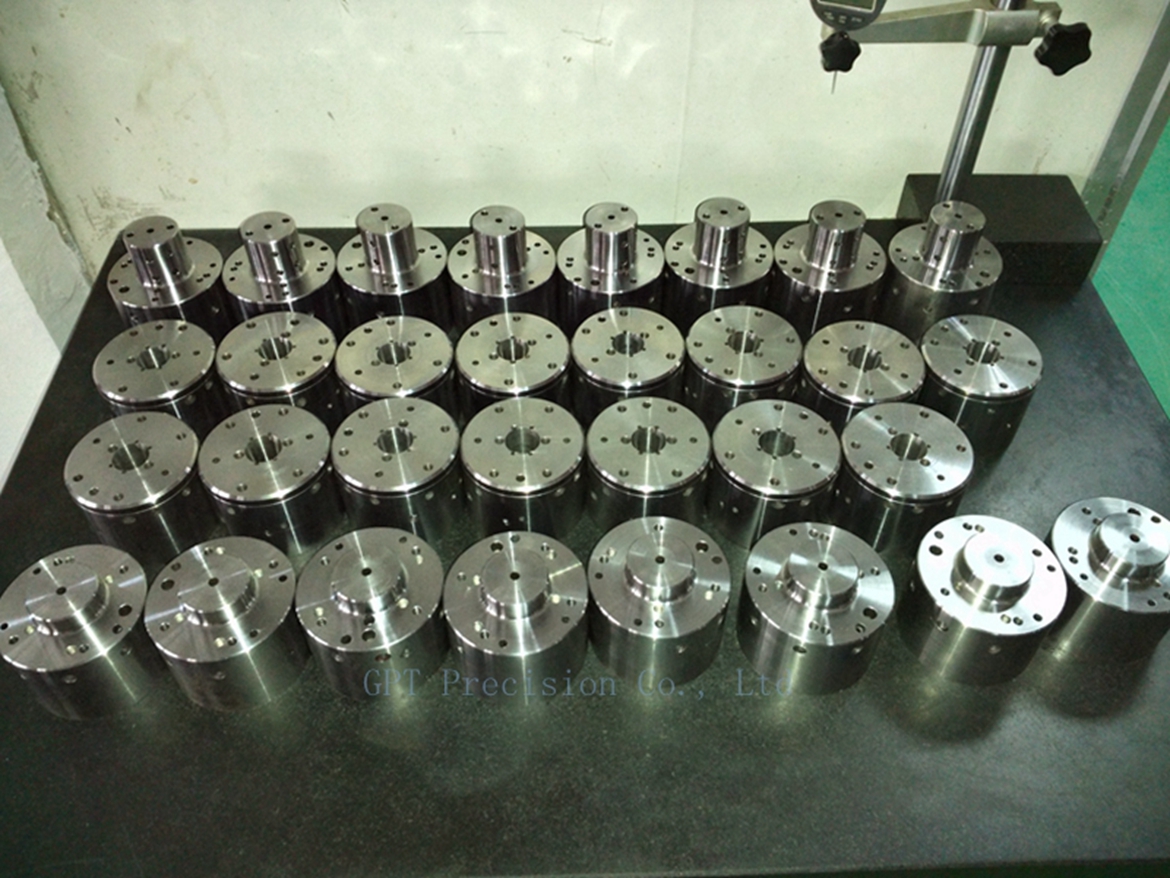

CNC rapid prototype custom manufacturer are generally according to the actual needs of customers to make prototype .Good quality prototypes have strong reliability and are more conducive to verifying the research of new products. You may wonder how the CNC rapid prototyping manufacturer guarantees the quality of the processing?

First, the CNC rapid prototyping manufacturer will start with the selection of materials, and the choice of materials is very important. Considering the strength, toughness and environmental performance of the material.

The second is the processing process. Under the strict and confidential production system, the skilled and experienced CNC rapid prototyping masters follow up the whole process to ensure stable processing quality.

Finally, the surface finish selects the appropriate process, and the steps are carried out to control the details. When the parts finished and it will be sent to our quality department for inspection. Key dimensions are measured and recorded on our FAI report. Each batch includes a FAI or OQC report. Then the parts will be packaged and sent to you

GPT Precision Co., Ltd has more than 10 years of combined experience in prototype machining, CNC manufacturing, vacuum casting service. and has a high-level technological group of 26 peoples. The processing quality of the rapid manufacturing is stable, the processing precision is high, and the appearance is exquisite. GPT Precision Co., Ltd has been providing high quality rapid prototype manufacturing services for major enterprises.

GPT Precision Co., Ltd .we use 3D printing to prototype your ideas and turn them into a reality. Thanks to advancements in 3D printing technology, the process has never been easier, more affordable or more accessible. At GPT Inc. we have many years of experience in 3D printing technologies and can walk you step by step through everything you need to start designing, printing, prototyping, and mass producing your product ideas. Get in touch today and we can help you refine and create your design so you’ll have a physical prototype in your hands in a week!