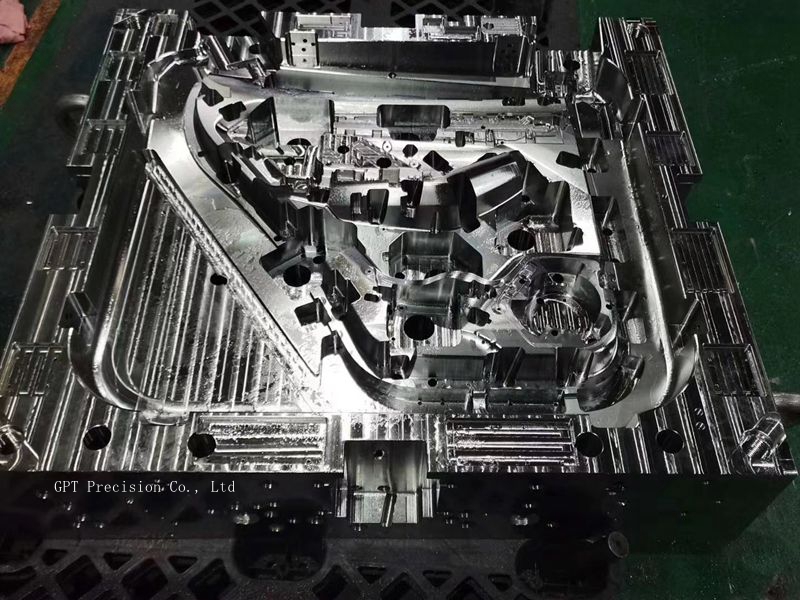

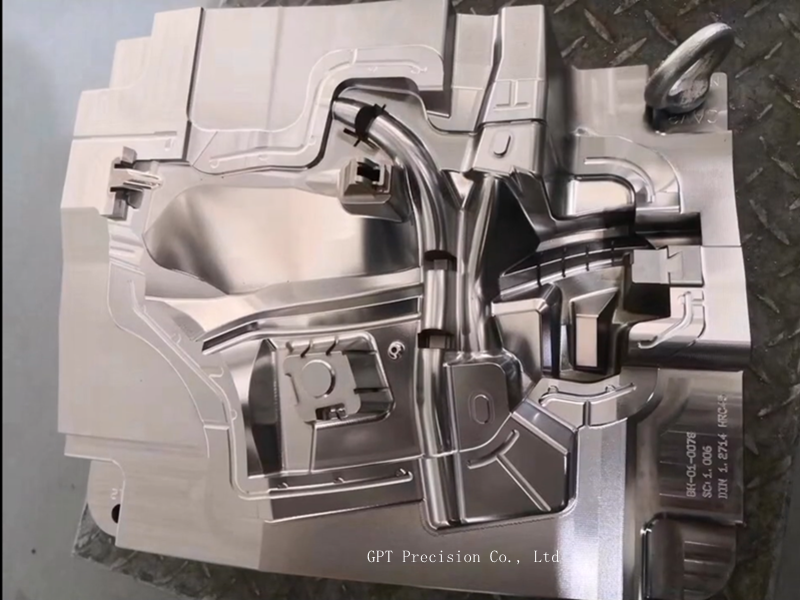

aluminium die casting mold

Get Latest Price

Min. Order / Reference FOB Price

Port: Shenzhen, China

Production Capacity:100

Payment Terms: L/C, T/T, D/P, Paypal, Western Union

Surface Treatments: Polishing, Texturing etc.

Application: Auto and Motorcycle Accessory, Machinery Accessory, Hardware Tool

Material: steel

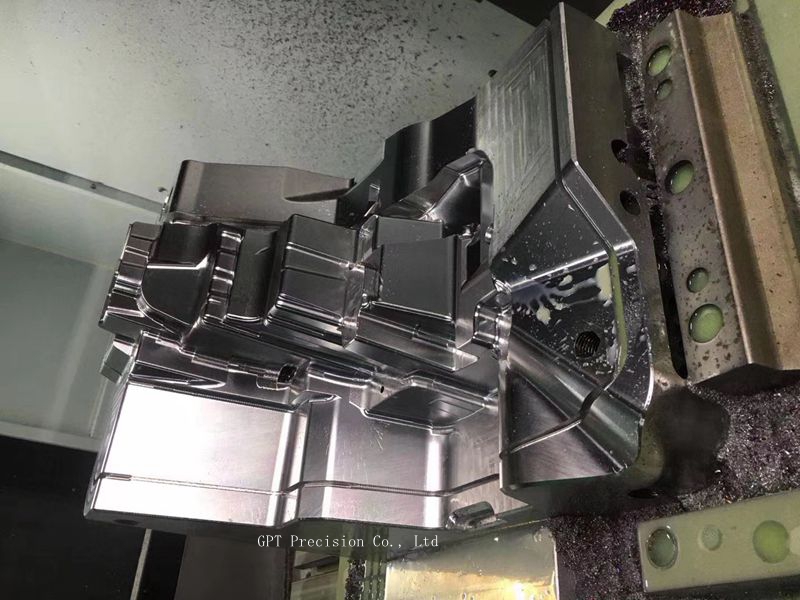

CNC Machining or Not:CNC Machining

Transport Package: Wooden Box

Specification: depend on inquiry

Trademark: GPT Precision

Origin: Shenzhen China

- Specifications

The mould to make the die-cast Aluminum molding is made of steel and consists of two shells to allow the extraction of the die-cast part. The materials used to make the various parts of the mould are always metals with higher melting points than the injected material, such as Aluminum.

The injection pressure of the molten material may vary depending on the weight of the piece to be obtained, but also the type of melting material used. It is important that the pressure is kept constant throughout the melting process until the workpiece solidifies. In the meantime, hydraulic presses ensure perfect and complete closing of the mould: once the piece has solidified, the presses allow the two semi-molds to open so that the die-cast part can be extracted.

Process of die-casting aluminum molding

The process of die-casting aluminum molding is automatized and computerized and therefore lends itself to high productivity. The constant control of the casting process ensures the best possible quality of die-cast parts and maximizes the production efficiency of their plants.

Thanks to the high technological and quality standards achieved today by equipment and machinery, the pieces produced by die casting ensure better minimum dimensional tolerances and surface finishes than other foundry processes.

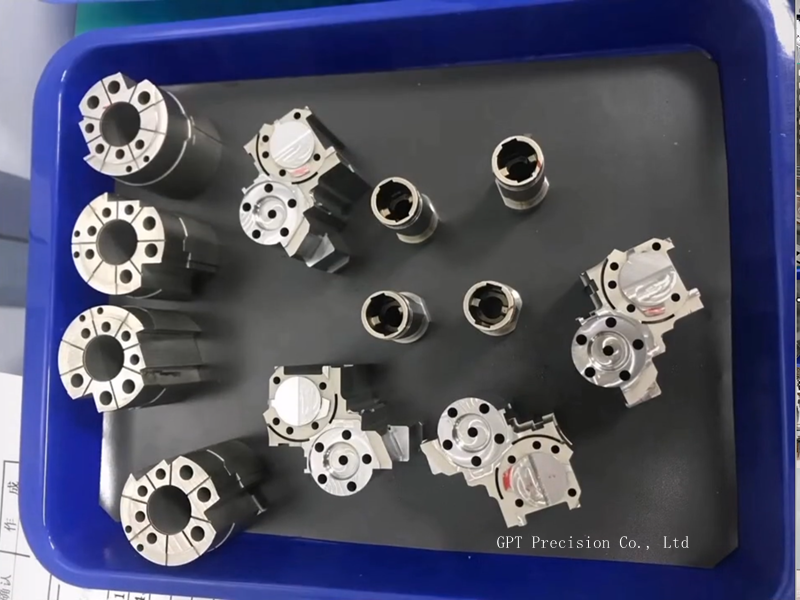

Thanks to the modern die-casting systems of aluminum and zinc alloys with capacities ranging from 100 to 1400 tonnes, GPT mold is able to manufacture high-tech items with weights ranging from 4 grams to 15 kilos, either in small, medium or large scale production.

Die casting tools made from hot work steels are one of our specialties. Thanks to decades of experience and close cooperation with our customers (die casters, producers of die casting machines), we tailor our products to match requirements such as: High wear resistance;High temperature strength;High temperature toughness;High temperature fatigue resistance;Low adhesion tendency;DIE CASTING ADVANCED STEEL GRADE;High Pressure Die Casting Mold.

Die casting molds from GPT mold Die Casting and Machining utilize aluminum alloys and zinc alloys to produce small to large run part identical castings for your manufacturing needs. Die cast mold development is a versatile process that enables the production of a large quantity of small to medium-size castings.

Contact GPT mold Die Casting and CNC Machining for Die Casting Molds Today

Contact us for more information regarding our aluminum and zinc alloy die cast molds and die cast molds processes, or request a quote for further pricing details today. We are an industry-leading provider of advanced die casting and CNC machining services.