Metal Surface Finishes

February 17, 2023

Below is some common metal surface finishes:

Anodized Metals

Machinists use this electrolytic passivation process to increase the thickness of the natural oxide layer on the surface of metals. Machinists anodize metals to increase their resistance to wear and corrosion. It also helps primers and glues adhere more easily to metal surfaces than ordinary metals do. If you anodized a metal, you would have altered the microscopic texture of the surface of the metal. Anodized metal surfaces seem to be harder than ordinary metal surfaces.

Powder Coated Metal Surface

This method requires the use of electricity to deposit a dry powder on the metal surface. After depositing powder on the surface electrostatically, the machinist moves the metal into an oven to obtain better adhesion of the powder on the metal surface through a chemical reaction.

This metal surface finish is widely used in the military industry, automotive industry, and tools manufacturing industry.

Pickling

This is a metal finishing process that can eliminate impurities and irregularities from a metal’s surface. This method requires the use of pickle liquor, an acidic substance. The liquor serves several purposes, including as additives that help to prevent metal corrosion. Therefore, machinists use pickling in almost all metal manufacturing processes. During the metal fabricating process, if a metal passes through a hot process, it may have an oxide layer on it.

This is where pickling comes in. It helps to clean up the surface, rendering it smooth by descaling. However, as a result of the acidic process of pickling, it may also cause corrosion by itself. Therefore, pickling is usually performed before other surface treatment processes. They will help to eliminate whatever problem that arises during pickling.

Polished Metal Surface

Polishing is the production of a shiny metal surface by using either physical rubbing or chemicals. It helps to produce a metal surface that has an excellent specular reflection surface. Another added advantage of finishing is that it can be used on new and used parts.

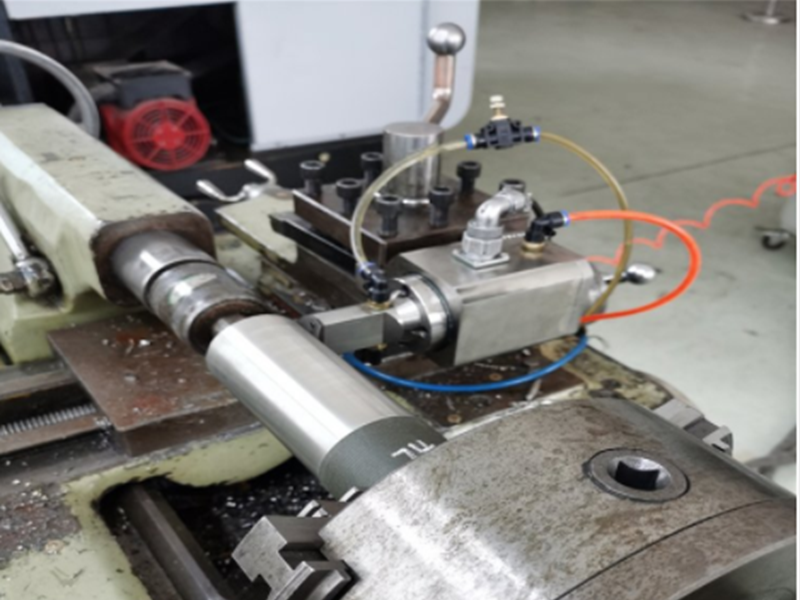

Grinded Metal Surface

This is a typical machining process that helps to remove irregularities on a metal surface. Machinists use this process after construction and before painting or coating. Grinding helps smoothen the metal surface, and it is done using a hand-held machine called a grinding wheel or grinder.

Some common metals that often pass through the grinding process are aluminum, mild steel, cast iron, and stainless steel.

Lapping

This precision technique is usually adopted when a metal surface is required to have a high degree of surface refinement and flatness. Skilled artisans use lapping as a metal finishing technique. The process involves using a soft iron tool with a mild abrasive slurry to work the metal surface gently. Lapping doesn’t require a special machine; it is usually done on small metal parts and by hand. A correctly done lapping will help to fill microscopic spots and flattens irregular surfaces.

At GPT, we offer quality surface finishing at reasonable prices. With us, you can save 30% of your budget. We know that you want quality finishing for your parts production without breaking the bank to get it; Just contact us through email, and we’ll attend to your needs. You can also upload your CAD file to get a quotation.