CNC lathing China services

Port: Shenzhen, China

Payment Terms: L/C, T/T, D/P, Western Union, Paypal, Money Gram

Application:Auto and Motorcycle Accessory, Machinery Accessory, Medical

Standard: GB, JIS Code, TEMA, ASME

Surface Treatment: Zinc plating, chrome palting ,nickel plating ,painting ,sand blasting ,powder coating ,polishing ,anodized ,baking finish ,oxidation ,electroplate ,passivate.

Production Type: Batch Production

Machining Method:CNC lathe Machining

Material: Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, Nylon

Transport Package:Plastic Box /Wooden Box/ Carton Box

- Specifications

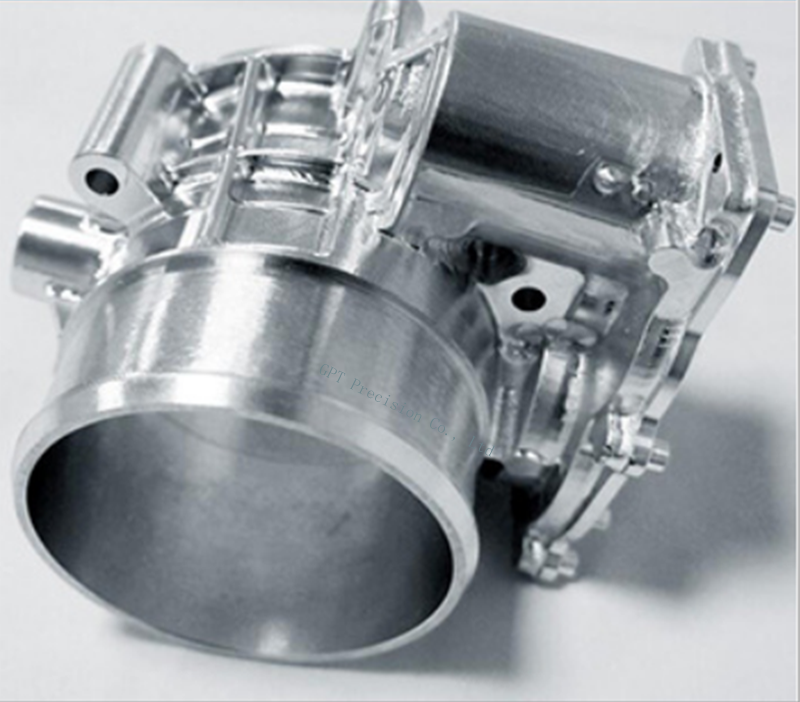

GPT Precision CNC Milling and Turning Surface Finishes

There is a wide range of metal finishing services available here for your CNC milling and CNC turning parts to improve the parts appearance, surface smoothness, corrosion resistance and other performance.

Painting: refers to an altering surface finishing process, spraying paint, pigment, or color to a solid surface as a colored protective layer, and can be done on metal or non-metal precision CNC turning components of any shapes, usually applied on aluminum, stainless steel , steel alloy parts and CNC lathe brass compenents. The purpose is to improve aesthetic appearance and prevent corrosion or oxidation.

Passivation: a common chemical surface treatment method for steel and stainless steel, to remove ferrous contaminants or use a light coat of protective material to create a shell for enhancing the corrosion resistance or reducing the chemical reactivity.

Electroplating/Plating: a process of using an electric current to reduce dissolved metal cations so that they form a thin coherent metal coating on an electrode, to change the properties of the metal surface or build up thickness for undersized parts.

Powder coating/Powder coat: a functional and decorative finish, which is applied as a free-flowing, dry powder, employs electrostatically and then cured under heat, to create a hard finish that is tougher than conventional paint. The main applications including household appliances, aluminum extrusions, drum hardware, automobile, motorcycle, and bicycle parts.

Anodizing/Anodized:an electrolytic passivation process of forming a thin layer of aluminum oxide on the exterior of aluminum CNC machined parts to increase the thickness of the natural oxide layer and protect the metal, as the layer has higher corrosion and abrasion resistance than aluminum.