OEM Custom Brass turning Services

Tolerance : 0.01-0.05mm can also be customized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Color: As customer's specific requirements

Standard: GB, EN, API650, China GB Code, JIS Code

Material: Stainless steel,mald steel,zinc alloy,aluminium alloy,brass,bronze,copper,etc.

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

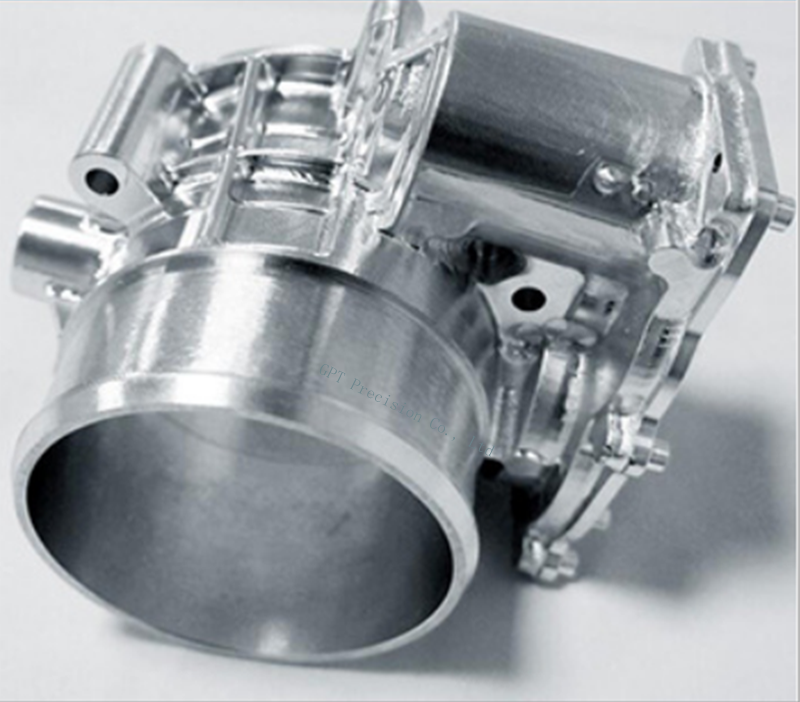

Precision Cnc Machining: 5/4/3 Axis 7075 Aluminum/304 Stainless Steel/brass Parts

Surface treatment: Zinc plating,chrome palting,nickel plating,painting,sand blasting,powder coating,polishing,anodized,baking finish,oxidation,electroplate,passivate

Delivery time: 7-30 days after receive the pre-payments

- Specifications

Brass is a kind of copper alloy with zinc as the main additive element, presenting beautiful yellow color. Brass is one of the easiest metals to machine with CNC machining, drilling, milling and turning tools, such as brass 360, brass 308. Brass CNC drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in the brass materials or parts, it’s often used to produce round holes for machine screws and bolts. The drill bit is pressed against the brass workpiece and rotating with speed at hundreds to thousands of revolutions per minute. CNC drilling can drill holes and other shapes at certain diameter and length, while achieving precision and productivity at the same time. Brass drilling is not a separate process, but often working with CNC Swiss turning and milling. CNC drilling brass parts applying in Jets, Aerospace, Pipe Fittings, Jewelry, Architectural, Marine Hardware and more industries with its low coefficient of friction, good malleability, wear resistance and high corrosion resistance.

GPT Precision is a top China custom CNC drilling services supplier, based on accomplished technicians with rich expertise and manufacturing staff with extensive experineces, our brass CNC turning machining and drilling capabilities enable us to deliver quality brass CNC turning parts and CNC turning steel components with high accuracy and precision and are consistence with customer design or drawings specifications. Our multi-function machining center can offer milling and turning services for CNC drilling brass parts. Multiple spindles in turrets with drills of various diameters have been mounted for fastest drilling. To ensure the safety, quality, reliability and performance of our product, design review and production inspection will be implemented strictly.

Benefits of Our OEM Custom Brass turning Services & Parts

– Multi-function machining center provides cost-effective brass milling parts

– High accuracy, precision, versatility and reproducibility

– One-stop service from quotation, design review, production, inspection to shipment

– Custom CNC drilling brass parts with specific hole sizes and diameters

– High production flexibility whether for a handful of prototypes or full production runs with large amounts

– Stable production capability for high efficiency and quality guaranteed

Features Of Brass Milling Parts

– Long shelf life

– Strong wear resistance

– Good malleability

– Flexible and rustproof

– Easy to shape

– Excellent tensile strength, rustproof