CNC Swiss turning services

Technique: Turning, drilling, milling, planning, boring. Grinding, gear-hobbing, wire-cutting, sawing, reaming, screwing, EDM machining, assembling and etc.

Precision: Average level: ±0.01mm, depending the part size and thickness and material

Quality System: 100% inspection(offer QC report)

Process type: Stamping Surface treatment: Sand blasting, polishing, brush, Anodized

Applied Software : PRO/E, Auto CAD, Solid Works,IGS,UG, CAD/CAM/CAE

Color: As customer's specific requirements

Standard: GB, EN, API650, China GB Code, JIS Code

Material: Stainless steel,mald steel,zinc alloy,aluminium alloy,brass,bronze,copper,etc.

Packing detail: Eco-friendly pp bag / EPE Foam /Carton boxes or wooden boxes

Delivery time: 7-30 days after receive the pre-payments

- Specifications

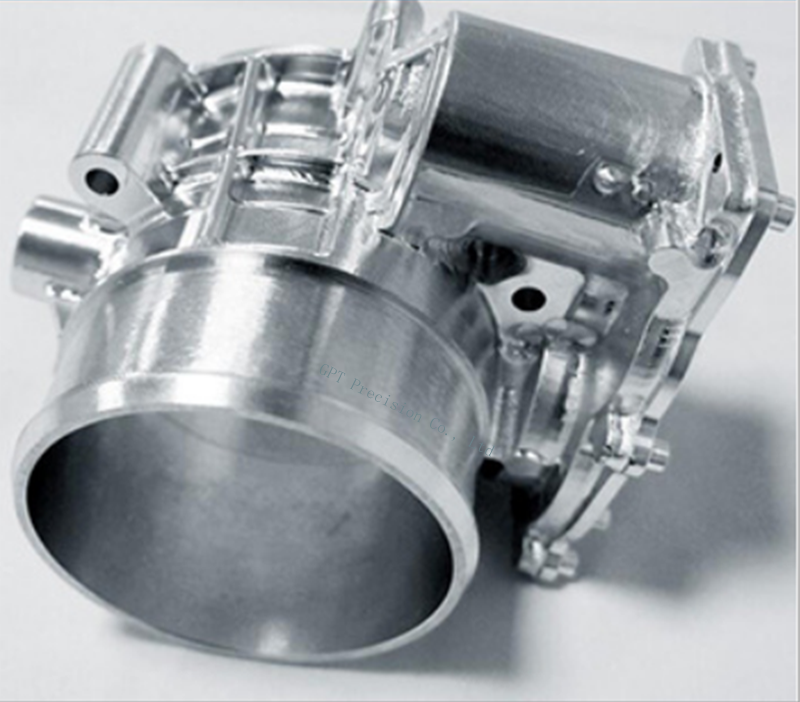

Custom CNC Turning parts Services – OEM China CNC Turning steel Parts Manufacturer & Company

GPT Precision is an experienced precision CNC turning services supplier, manufacturer, exporter in China, has been specialized in offering best OEM Custom Brass turning Services for superior quality cheap CNC turning parts, CNC lathe parts or high precision machined components with the operation of an impressive range of state-of-the-art turning machines, such as washers, bolts, shafts, rivets, spacers, sleeves, nipples, stainless steel fittings, pipe fittings, light fittings, wheel studs, etc. Our advanced CNC turning center routinely works with a wide variety of materials, ranging from copper, brass, stainless steel, carbon steel, aluminum, and titanium. We can always choose a suitable precision turning process to reach your requirements. Our custom CNC machining services ensure that our customers receive the highest quality CNC turned parts.

Benefits of Swiss Machining

The piece is held steady in the position near the operation point and not affected by the force of tools, the precision can be maintained in tight tolerance.

Small parts with complex profiles and configurations can be manufactured, including thin walls, deep cuts, and more intricate features.

Because the Swiss machine can perform multiple operations at once, the production speed is much higher than common lathes.

Fewer needs for secondary processing and treatment, a shorter cycle of the production run.

What is Swiss Machining?

Typically, Swiss machining refers to a precision manufacturing process in which parts are produced using specialized Swiss type CNC lathes, on the Swiss machines, the part is rotated in a radial motion when being cut. Because of the unique design of the Swiss machine, CNC Swiss turning services allow multiple operations are executed simultaneously in several zones in a short time. Therefore, its machining speed is greatly improved. This type of CNC machining technology often used for small precision CNC turned parts projects.

How Does a Swiss Lathe Work?

A Swiss machine (Swiss CNC machine), also known as Swiss screw machine, Swiss lathe, Swiss automatic and sliding headstock lathe, which is developed in 19th century Switzerland, its initial function is to support the mass production of micro screws. Swiss type machines can achieve higher precision and accuracy than traditional lathes, especially when producing extremely small parts. On a traditional CNC turning lathe, the part is held firmly at one or both ends, and can only rotate in a fixed position, so the machine can only perform one operation at once, while with a Swiss lathe, the workpiece can both turn and move back and forth along the Z-axis, it can perform multiple operations at one time. The bar stock is feed through a guide bushing and tools are mounted to the face of the guide bushing, so the force is right where the material is emerging from the bushing, which minimizes the tool force effects of the part, then ensures greater precision. In addition, Swiss turning machines can not only manufacturing turned parts but also applicable to the use of producing complex profiles without turned surfaces.