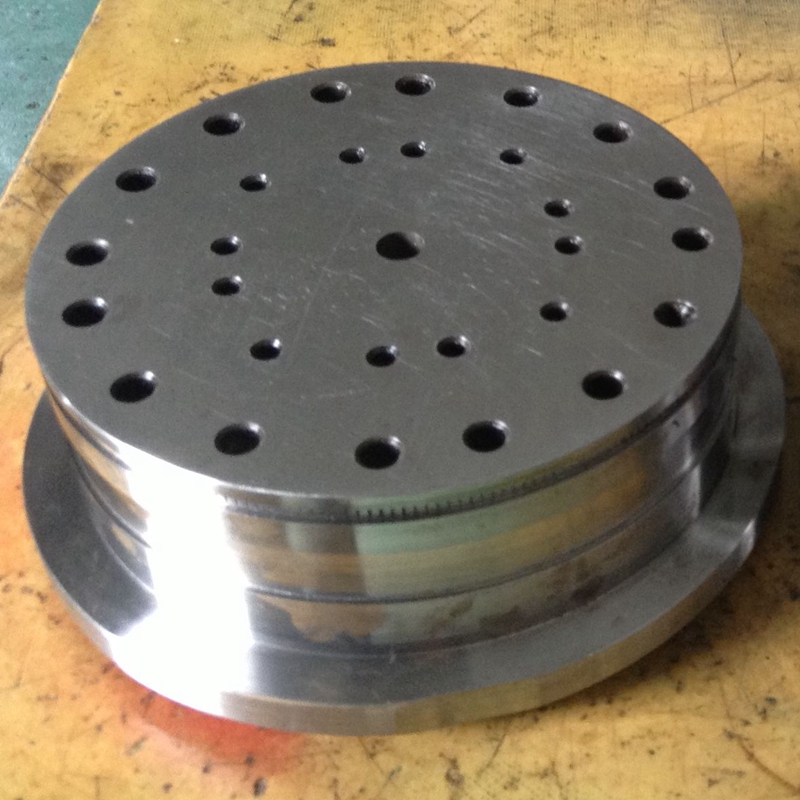

Custom machined parts

■ In-house tooling design (we have more than 17 rich-experience mold designer)

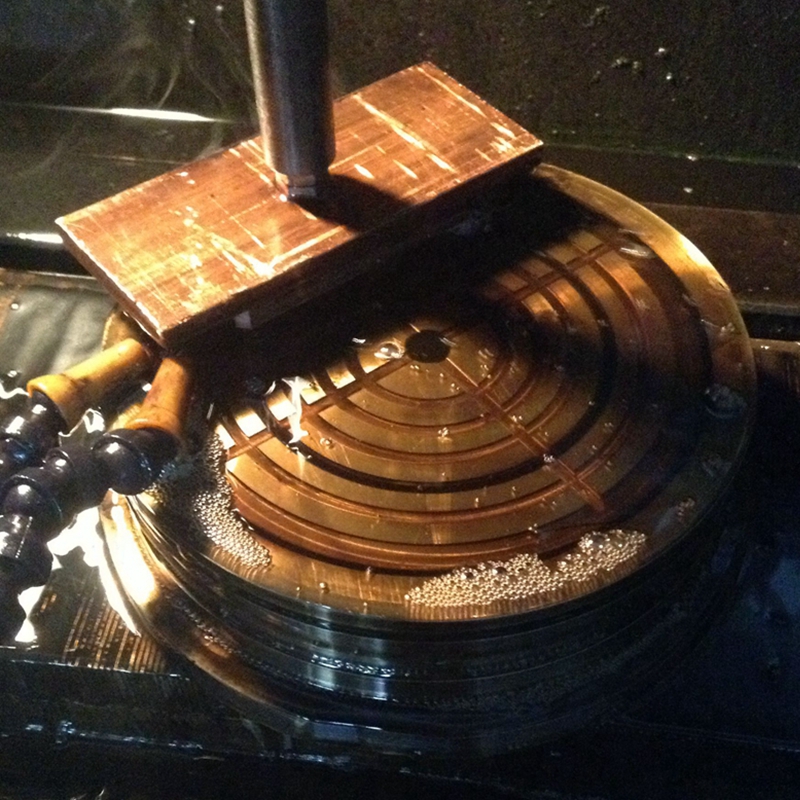

■ High precision Wire cut EDM

■ Mirror polishing EDM

■ Mold flow Analysis (before mold design, we should run mold flow analysis to avoid the potential trouble-shot on mass production, optimize the mold design to benifit plastic injection mold making.

- Specifications

Our GPT CNC machining centers are ideal for working with steel, aluminum, brass, carbon steel, and other specialty materials. We can provide a number of custom finishing services, such as full anodizing, carbon blacking, hard coating for aluminum custom CNC machined parts, and electrogalvanizing for steels and ferric materials.

Our team also offers a variety of other machining services to take your unique project all the way from conception to realization with help from our expert engineers. In addition to providing conventional milling, drilling, turning, and sawing, we are well-equipped for the specialty grinding and part-marking processes required by many modern applications. And, if needed, our certified partners can provide heat treating, welding, plating, and painting services before final inspection, assembly, and packaging. This comprehensive package of services helps ensure cost certainty for all of our clients, as well as quality control that competitors simply can’t match.

Our cutting-edge Swiss screw machines are well-suited to fabricating difficult pieces, such as long parts, custom complex machining parts with a variety of functions in a single setup, and high-accuracy parts with strict tolerance requirements. For these high-precision components, GPT utilizes electrical discharge machining (EDM). EDM makes use of a thin, electrically charged wire to erode small volumes of material in order to create the desired shape. The ability to cut fine part features into hardened alloys makes EDM particularly useful for fixtures, inspection gauges, and other profile or contour work.

Our advanced turning centers allow for rapid delivery of prototypes, flexible order quantities, reduced tooling costs, and tighter tolerances than traditional machine work, all backed by our skilled engineers. In addition to our standard vertical milling machines, we work with horizontal milling centers for larger runs; this equipment can operate at higher speeds and allows us to optimize for cost-efficiency when needed.

Common CNC Parts and Applications

Beyond basic custom metal components, GPT Precision also machines specialty plastic parts for critical applications in the medical and telecommunications industries. For medical device machining, which require the utmost precision and a painstaking design process, we can ensure optimal performance, longevity, and safety, providing peace of mind for practitioners and patients alike.

Our expert team has produced surgical and dental instruments, anesthetic and therapy components, diagnostic devices, catheters, mandrels, orthopedic, cardiac implants, and other implantable devices. We’ve also produced custom CNC parts for cable and satellite companies, as well as customers in the optics industry.