Rapid Prototype Machining

Port: Shenzhen, China

Production Capacity:50000PCS/Year

L/C, T/T, D/P, Western Union, Paypal, Money Gram

Application: Auto and Motorcycle Accessory, Customized Prototype

Standard: GB, EN, API650, China GB Code, JIS Code, TEMA, ASME

Surface Treatment: Polishing, Anodizing, Painting, Silk Print, etc

Production Type: Samples to Low Quantity Production

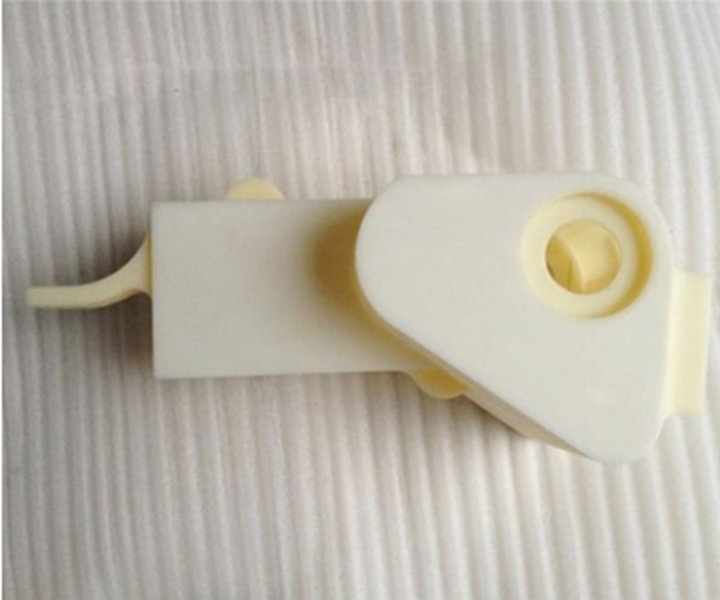

Machining Method:3D Print

Material: Plastic

- Specifications

CNC COMPUTER NUMERICALLY CONTROLLED MACHINING

cnc milling rapid prototype part

In machining, a solid block (or rod stock) of plastic or metal is clamped into a CNC mill or lathe respectively and cut into a finished part through a subtractive process. This method generally produces superior strength and surface finish to any additive manufacturing process. It also has the complete, homogenous properties of the plastic because it is made from solid blocks of extruded or compression molded thermoplastic resin, as opposed to most additive processes, which use plastic-like materials and are built in layers. The range of material choices allows parts to be made with the desired material properties, such as: tensile strength, impact resistance, heat deflection temperatures, chemical resistance, and biocompatibility. Good tolerances yield parts suitable for fit and functional testing, jigs and fixtures, and functional components for end-use applications. A number of CNC rapid prototype factory, use 3-axis milling and 5-axis indexed milling processes along with turning to manufacture parts in a range of engineering-grade plastics and metals.

Pros

Machined parts have good surface finishes and are quite strong because they use engineering-grade thermoplastics and metals. Like 3D printing, custom Rapid Prototyping can be delivered in as fast as one day at some suppliers.

Cons

There may be some geometry limitations associated with CNC machining, and it is sometimes more expensive to do this in-house than 3D printing processes. Because the process is removing material instead of adding it, milling undercuts can sometimes be difficult.